Polypropylene composition toughened by elastomer and preparation method of composition

A polypropylene composition and elastomer technology, applied in the field of elastomer toughened polypropylene composition and its preparation, can solve problems such as insufficient toughness of polypropylene, and achieve the effects of good fluidity, lower cost and better compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

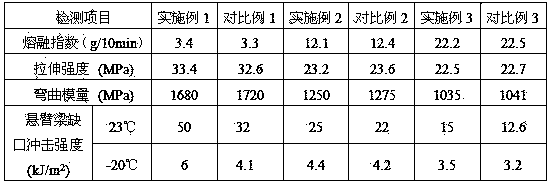

Embodiment 1

[0038] Put 50 parts of homopolypropylene, 5 parts of metallocene propylene-ethylene elastomer, 20 parts of talc, 0.1 part of antioxidant 1010, and 0.2 part of antioxidant 168 into a high-speed mixer for 3-5 minutes. The mixed raw materials are melt-extruded with a twin-screw extruder and pelletized. The temperature of the feed section is 160°C, the temperature of the compression section is 180°C, the temperature of the plasticizing section is 200°C, the temperature of the homogenization section is 200°C, and the temperature of the die opening is 190°C.

[0039]

Embodiment 2

[0044] Put 70 parts of random copolymer polypropylene, 3 parts of metallocene propylene-ethylene elastomer, 12 parts of calcium carbonate, 0.15 parts of antioxidant 1010, and 0.3 parts of antioxidant 168 into a high-speed mixer and dry mix for 3-5 minutes , melt and extrude the mixed raw materials with a twin-screw extruder, and granulate. The temperature of the feed section is 180°C, the temperature of the compression section is 220°C, the temperature of the plasticizing section is 220°C, the temperature of the homogenization section is 220°C, and the temperature of the die mouth is 220°C.

[0045]

Embodiment 3

[0050] Put 90 parts of block copolymer polypropylene, 1 part of metallocene propylene-ethylene elastomer, 5 parts of barium sulfate, 0.2 parts of antioxidant 1010, and 0.4 parts of antioxidant 168 into a high-speed mixer and dry mix for 3-5 minutes , melt and extrude the mixed raw materials with a twin-screw extruder, and granulate. The temperature of the feed section is 170°C, the temperature of the compression section is 200°C, the temperature of the plasticizing section is 210°C, the temperature of the homogenization section is 210°C, and the temperature of the die mouth is 200°C.

[0051]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com