Automatic cleaning device for aluminum electrolyzed anode scrap

An automatic cleaning and anode butt technology, which is applied in the field of aluminum electrolysis equipment components, can solve the problems of high performance requirements of guide rods and carbon blocks, high noise, and low cleaning efficiency, so as to improve the operating environment of employees, and the barrier effect is obvious. The effect of cleaning speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

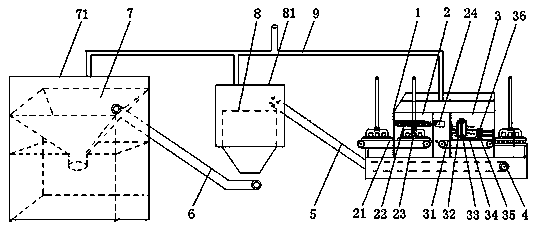

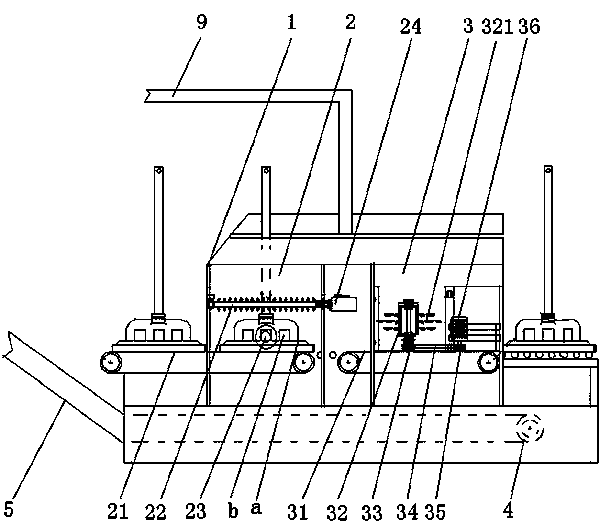

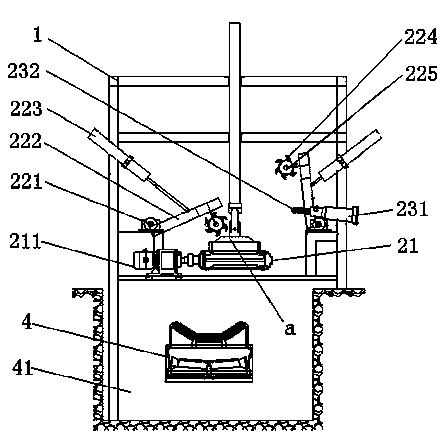

[0031] Such as figure 1 , figure 2 , image 3 , Figure 4 .

[0032] The aluminum electrolysis residual anode automatic cleaning device provided by the present invention includes a cleaning machine and a conveyor. The cleaning machine includes a frame 1, and a rough cleaning mechanism 2 and a fine cleaning mechanism 3 are arranged on the frame 1 in turn, and are arranged on the coarse and fine cleaning mechanisms. The first conveyor 4 below the mechanism 2, 3, wherein:

[0033] Described coarse cleaning mechanism 2 comprises the second conveyor 21, and this second conveyor 21 is a conveying chain, and the second conveyor 21 is driven by motor 211, and the swing type that is located at the front and rear sides of the second conveyor 21 picks up material Device 22, a telescopic scraper 23 located on the front side of the second conveyor 21; said swi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com