A hybrid drive type shape memory alloy linear drive device

A technology of memory alloy and hybrid drive, which is applied in the direction of machines/engines, mechanisms for generating mechanical power, mechanical equipment, etc., can solve the problems of intelligent materials such as refractory periods, and achieve the effects of light weight, improved compactness, and high speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

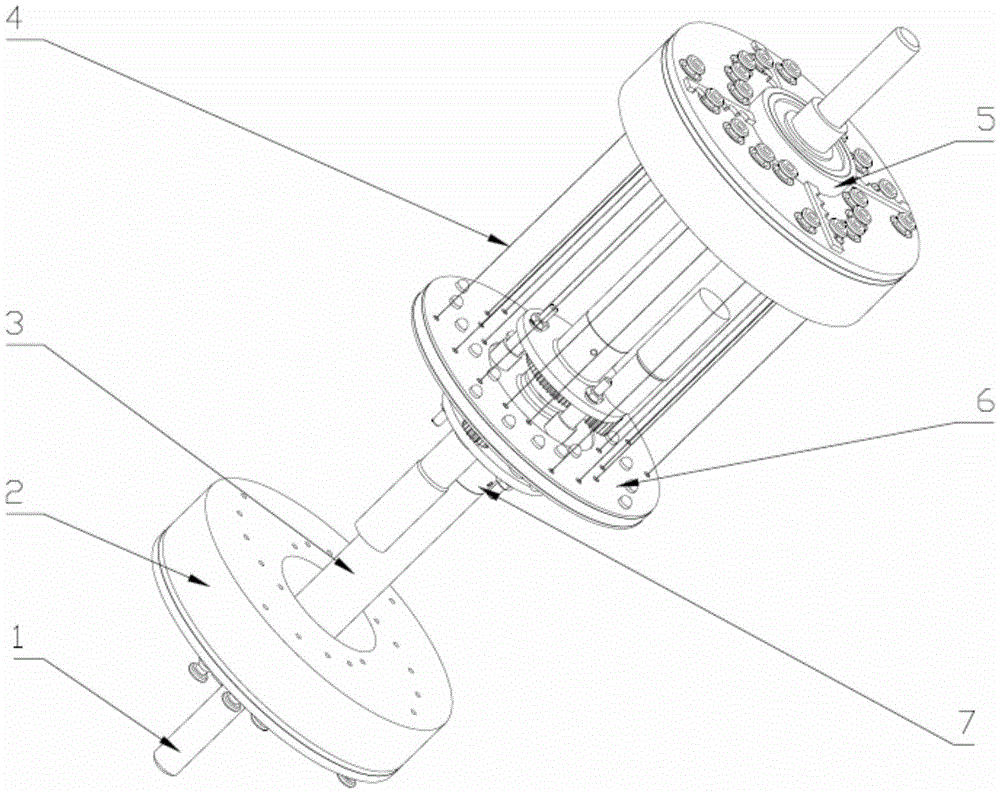

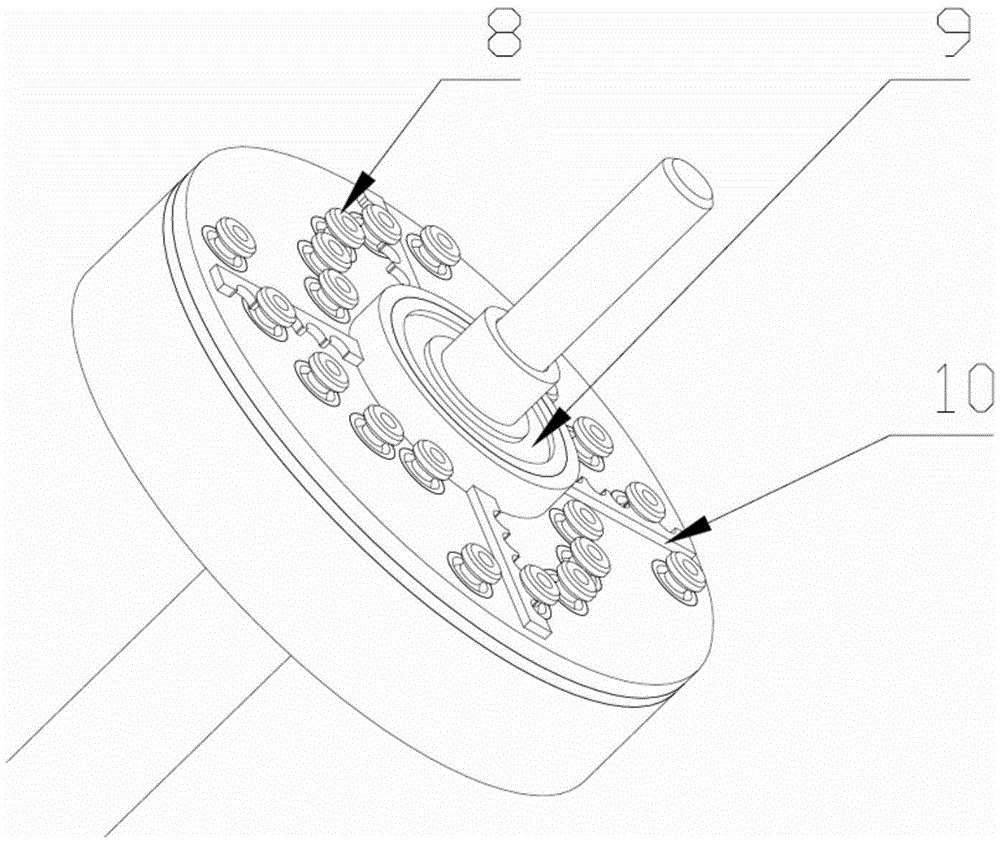

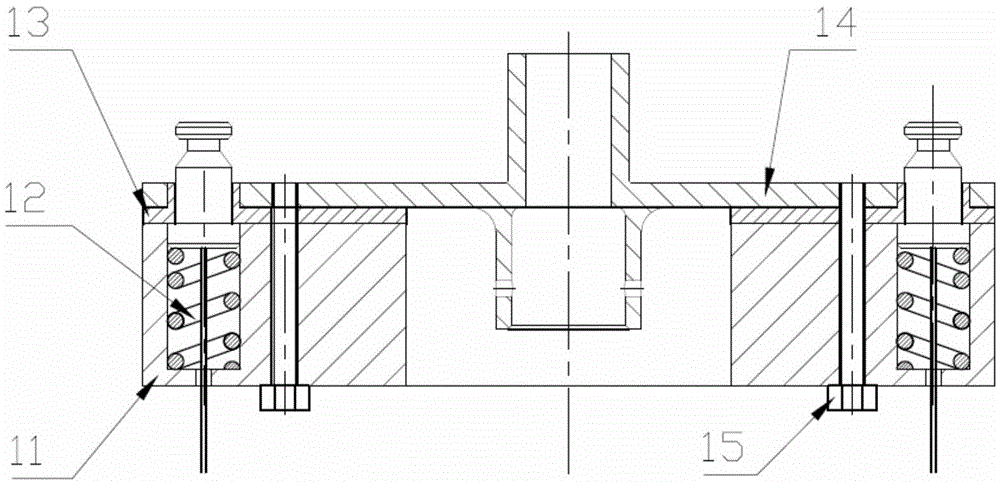

[0040] Such as figure 1 Shown is a schematic structural diagram of a hybrid drive shape memory alloy linear drive device provided by the present invention. The structure constituting the linear drive device includes two end caps and end block assemblies 2, two sleeves 3, two small end caps 7 and Figure 4 The frame formed by the connecting rod 16, spring washer 17 and nut 18 shown in the frame has a lead screw 1 passing through the center of the frame, and a cumulative displacement output assembly 6 is provided between two small end caps 7. The end cover and end block assembly 2 at both ends of the frame are provided with a piston and a conversion chuck device 5 to realize the work rotation of the SMA wire 4, and are distributed at corresponding positions between the cumulative displacement output assembly 6 and the piston and conversion chuck...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com