Furnace-front quick evaluation method of structure and performance of gray cast iron

A technology of microstructure performance and gray cast iron, which is applied in the field of rapid evaluation of the microstructure and performance of gray cast iron before the furnace, can solve the problems of increasing difficulty and the role of subjective factors, and achieve the effect of avoiding human factors and strong self-adaptation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

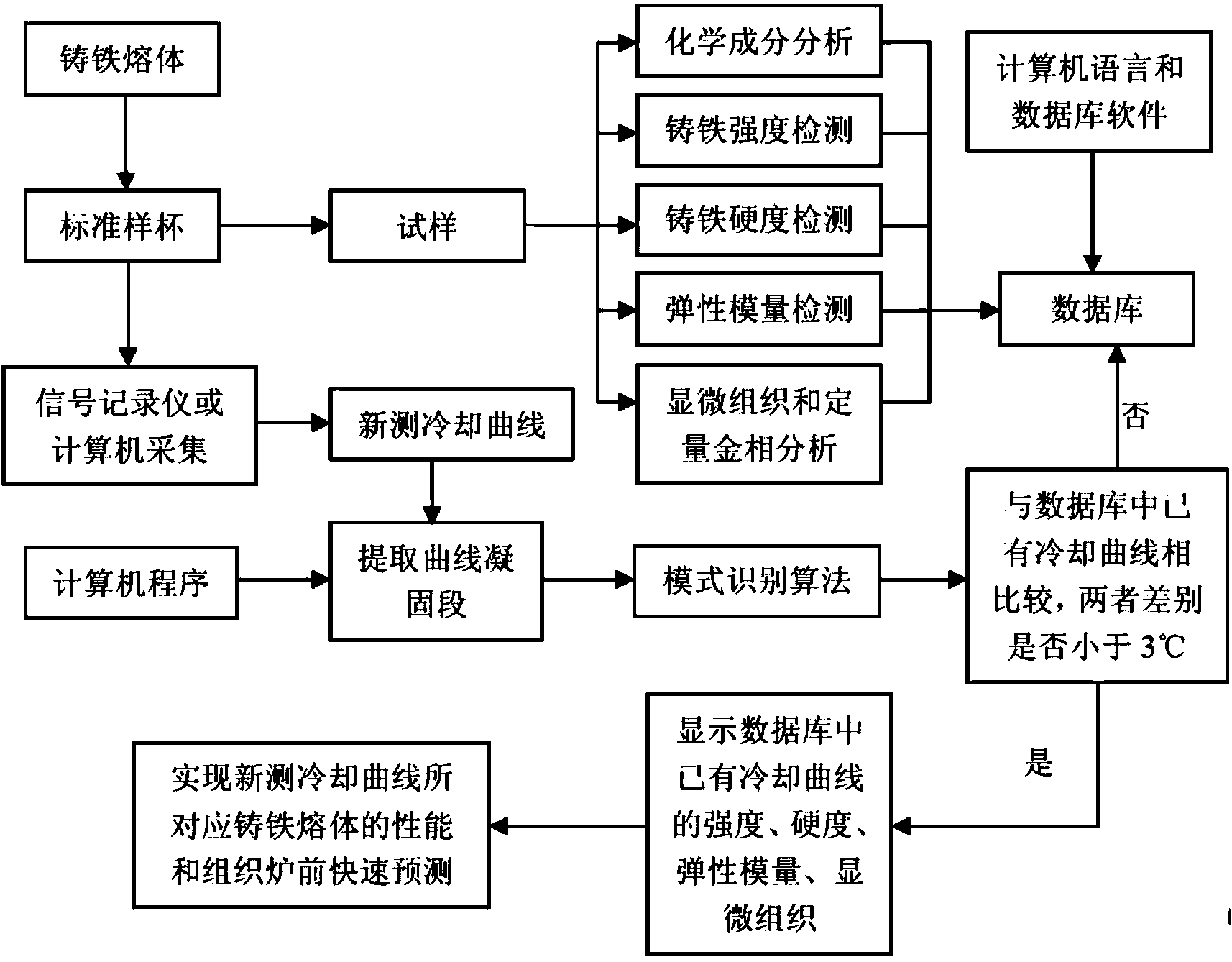

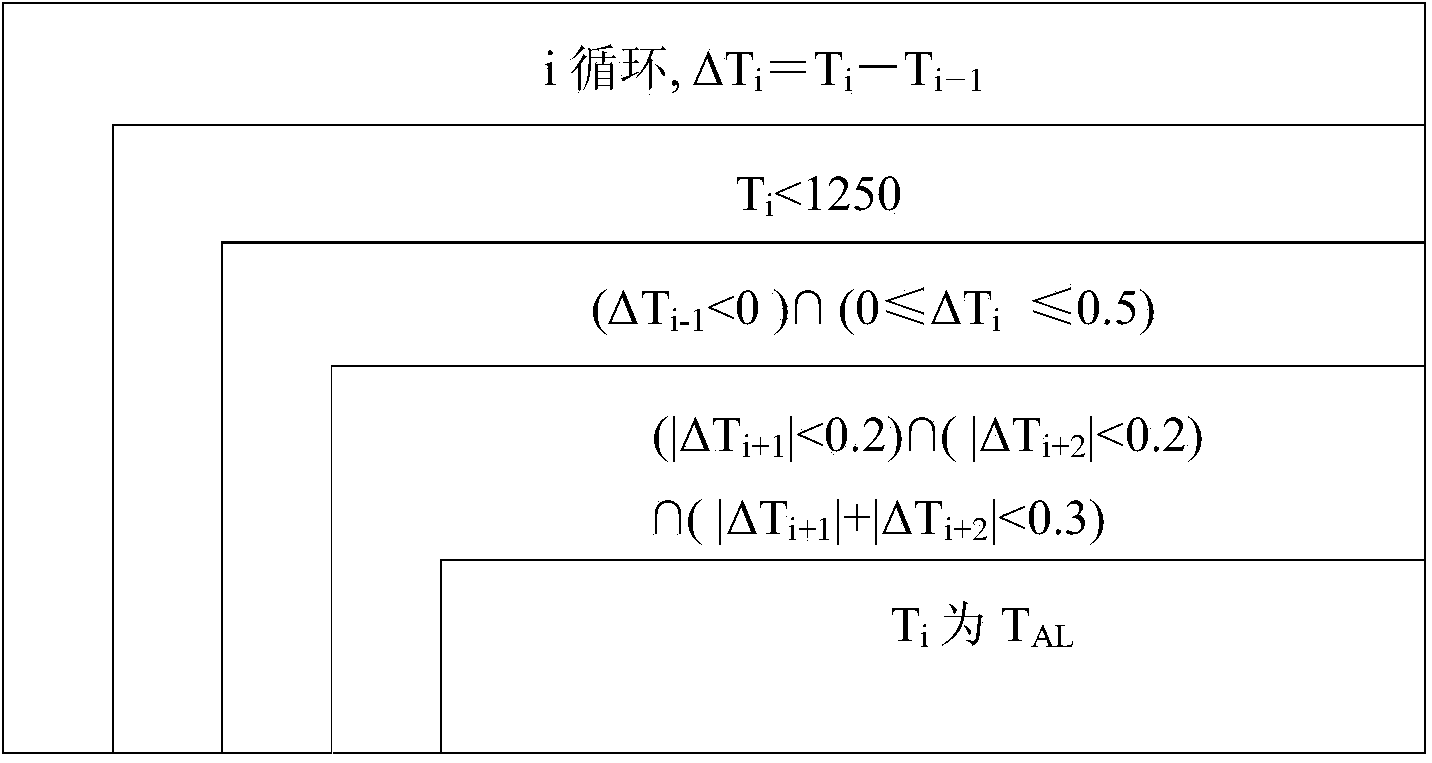

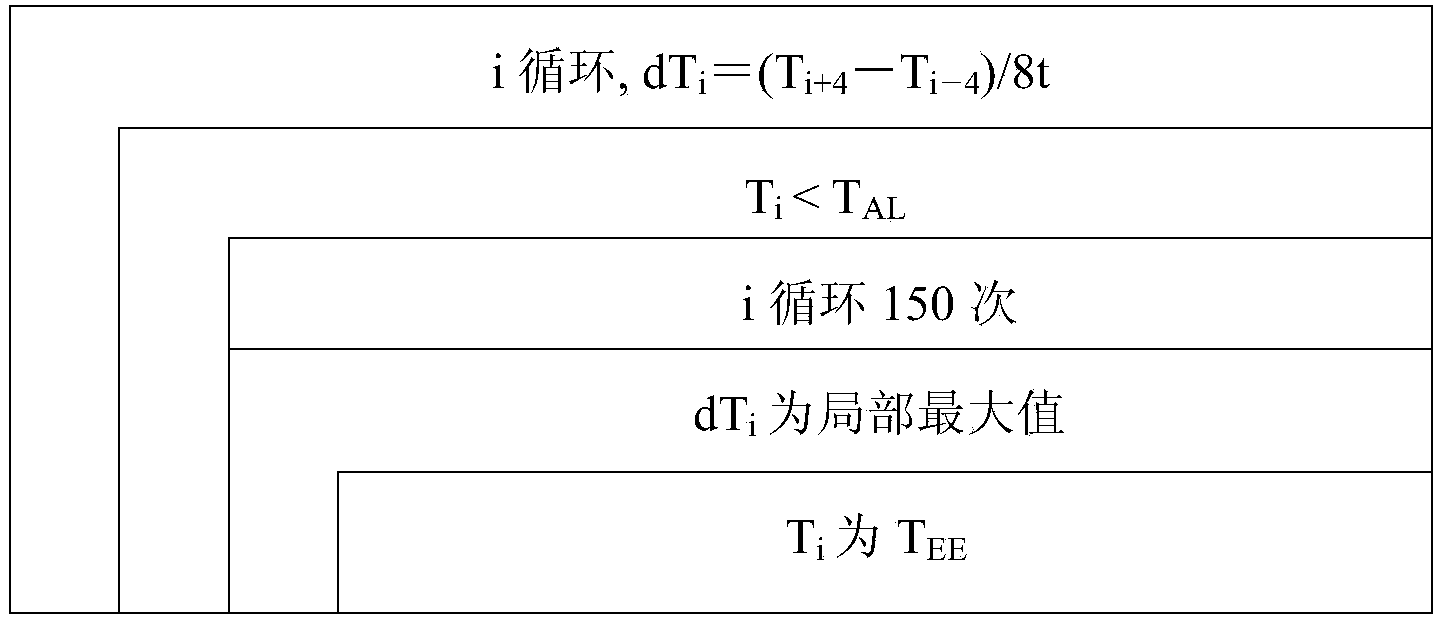

Method used

Image

Examples

Embodiment 1

[0084] The industrial frequency induction furnace is used to smelt molten gray cast iron, and the cast iron grade is HT250. The ingredients are cast pig iron, scrap steel, reclaimed materials, and intermediate alloys; the tapping temperature is 1460-1480°C, 0.25% of SiFe alloy is added to the tapping trough to inoculate with the flow, and the pouring temperature fluctuation range is controlled at 60°C. The thermal analysis sample cup is used to collect the cooling curve of gray cast iron during solidification, and at the same time, the composition test block used by the spectrometer, the round bar sample for testing mechanical properties and the microstructure analysis sample are cast.

[0085] Figure 4 The solidification section of the two relatively similar cooling curves of gray cast iron in Example 1 has a comprehensive deviation Cd of 2.17°C.

[0086] Figure 5 It is the metallographic structure corresponding to the two gray cast iron cooling curves with the integrated deviat...

Embodiment 2

[0089] The industrial frequency induction furnace is used to smelt molten gray cast iron, and the cast iron grade is HT250. The ingredients are cast pig iron, scrap steel, reclaimed materials, and intermediate alloys; the tapping temperature is 1460-1480°C, 0.25% of SiFe alloy is added to the tapping trough to inoculate with the flow, and the pouring temperature fluctuation range is controlled at 60°C. The thermal analysis sample cup was used to collect the cooling curves of the molten iron at the end of the inoculation treatment steel and the end of the incubation treatment for a long time, and the microstructure analysis samples were cast at the same time.

[0090] Image 6 These are two solidified sections of gray cast iron cooling curves with large differences in Example 2, which are the cooling curves corresponding to good and poor inoculation.

[0091] Figure 7 It is the metallographic structure corresponding to the cooling curve corresponding to good inoculation (A) and poo...

Embodiment 3

[0094] The industrial frequency induction furnace is used to smelt molten gray cast iron, and the cast iron grade is HT250. The ingredients are cast pig iron, scrap steel, reclaimed materials, and intermediate alloys; the tapping temperature is 1460-1480°C, 0.25% of SiFe alloy is added to the tapping trough to inoculate with the flow, and the pouring temperature fluctuation range is controlled at 60°C. The thermal analysis sample cup was used to collect 30 cooling curves of gray cast iron during solidification, and at the same time, round rod samples for testing mechanical properties and microstructure analysis samples were cast.

[0095] Figure 8 It is the relationship between the comprehensive deviation value Cd and the percentage difference of type A graphite in Example 3.

[0096] Picture 9 It is the relationship between the comprehensive deviation value Cd and the difference in tensile strength in Example 3.

[0097] Picture 10 It is the relationship between the comprehensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com