Light path precise adjusting and converting device in ultra-high vacuum test cavity

An ultra-high-vacuum, precision-adjusted technology, applied in the exposure device, installation, optics, etc. of the photo-engraving process, it can solve the problems of reducing system output, affecting the uniformity of engraving, reducing the reflectivity of optical surfaces, etc., and achieving fast and accurate positioning and focusing , high positioning accuracy, and the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

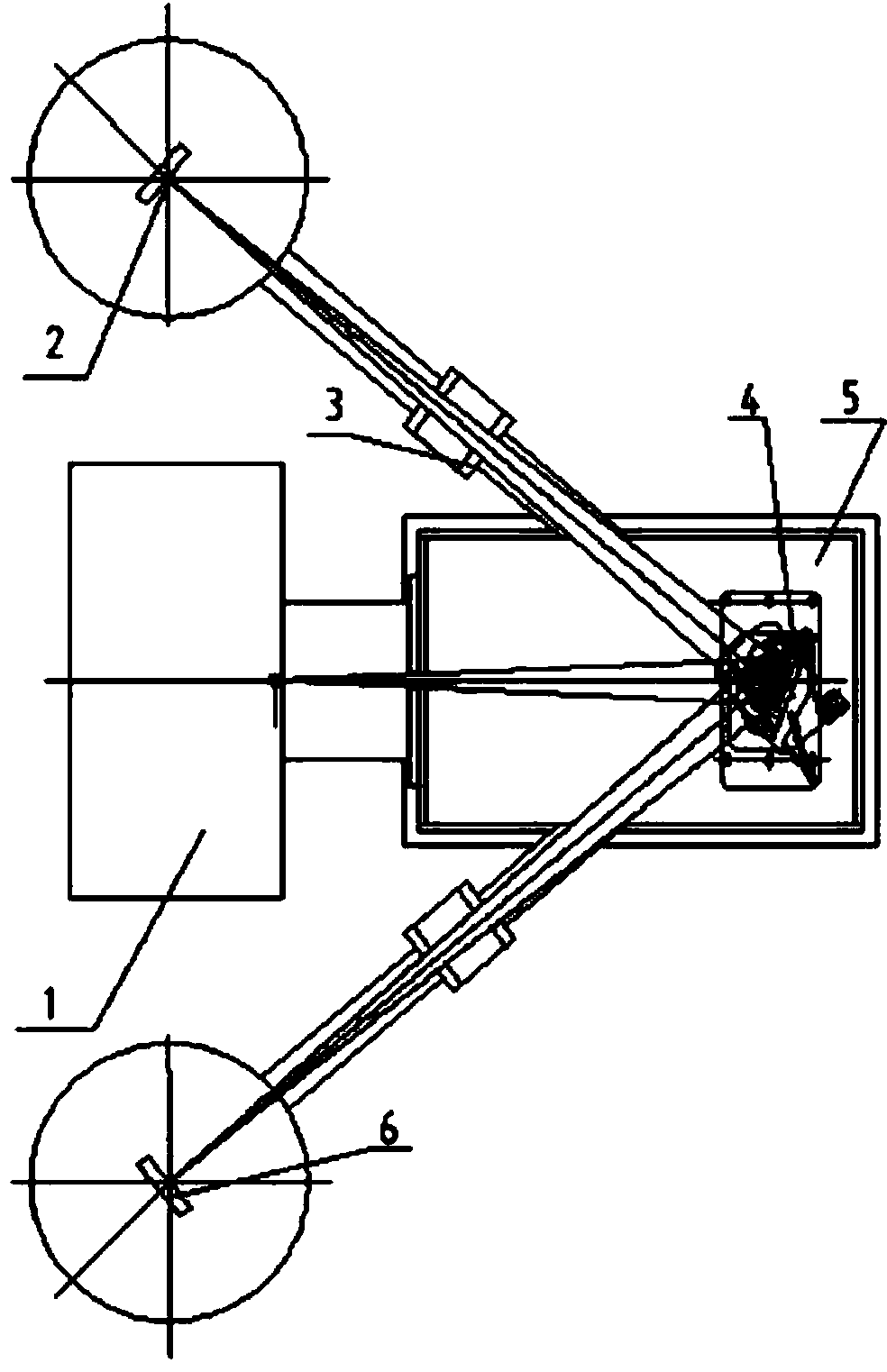

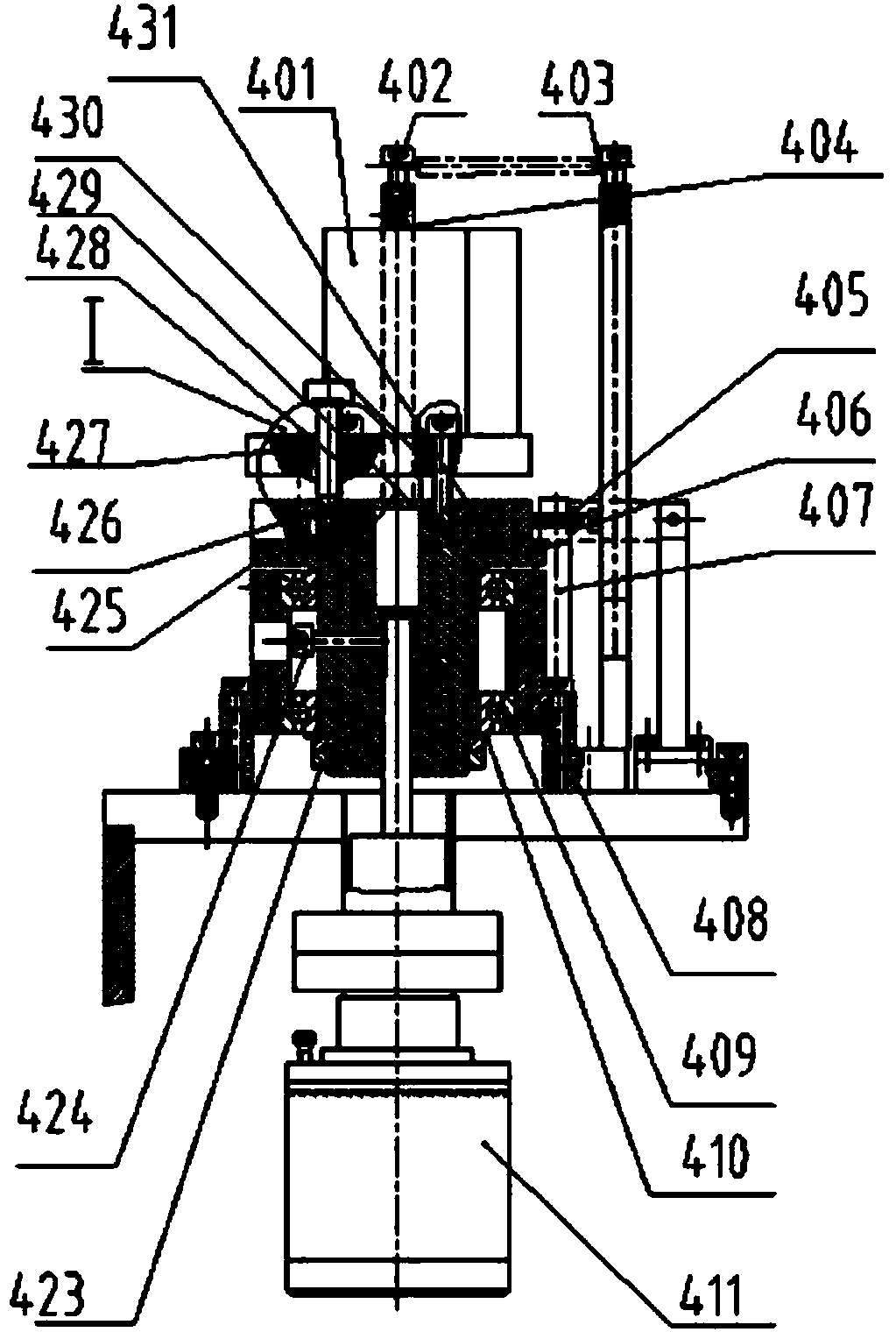

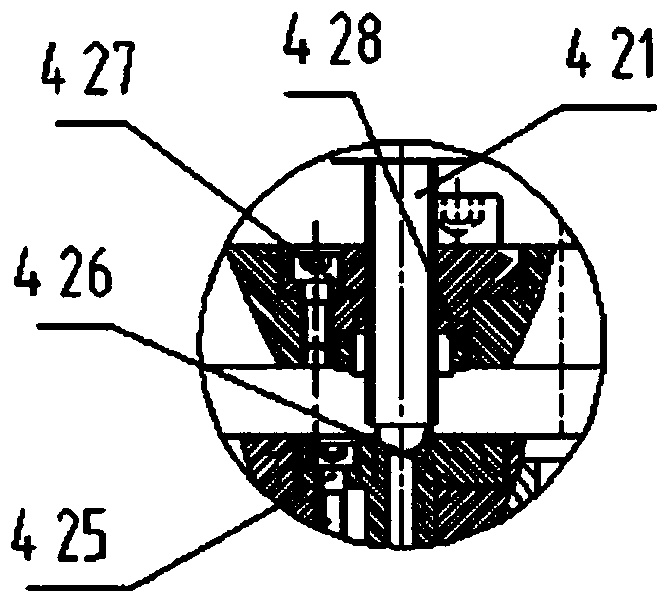

[0021] Such as figure 1 As shown, the assembly of the optical path fine adjustment and conversion device 4 is firstly assembled and the reflector 412 is adjusted and positioned, and the combination of the optical path fine adjustment and conversion device 4 is installed in the mirror group vacuum chamber 5 through the bottom plate 420 of the assembly And fix it with screws; and ensure that the angle required by the design of the rotation makes the light of the EUV light source 1 focus on the samples in the sample contamination chamber 2 and the exposure chamber 6 respectively; use the gate valve 3 to separate the mirror group vacuum chamber 5 according to the design requirements It is connected and sealed with the sample contamination chamber 2 and the exposure chamber 6; finally, the EUV light source 1 is coaxially connected and sealed with the mirror group ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com