A voltage equalizing circuit with supercapacitors in series

A supercapacitor, series voltage equalization technology, applied in battery circuit devices, circuit devices, current collectors, etc., can solve the problems of large circuit structure, reduced reliability, increased cost, etc., to reduce operating frequency, reduce switching loss, and even The effect of fast pressing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

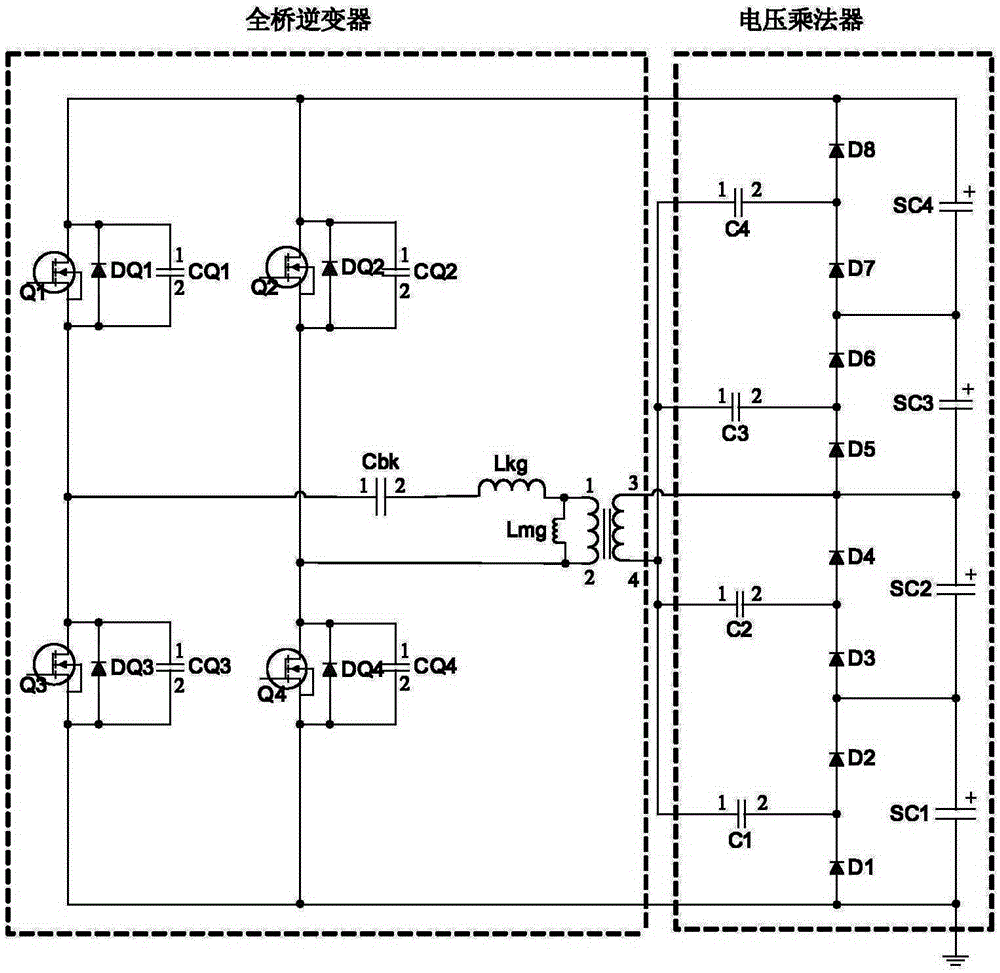

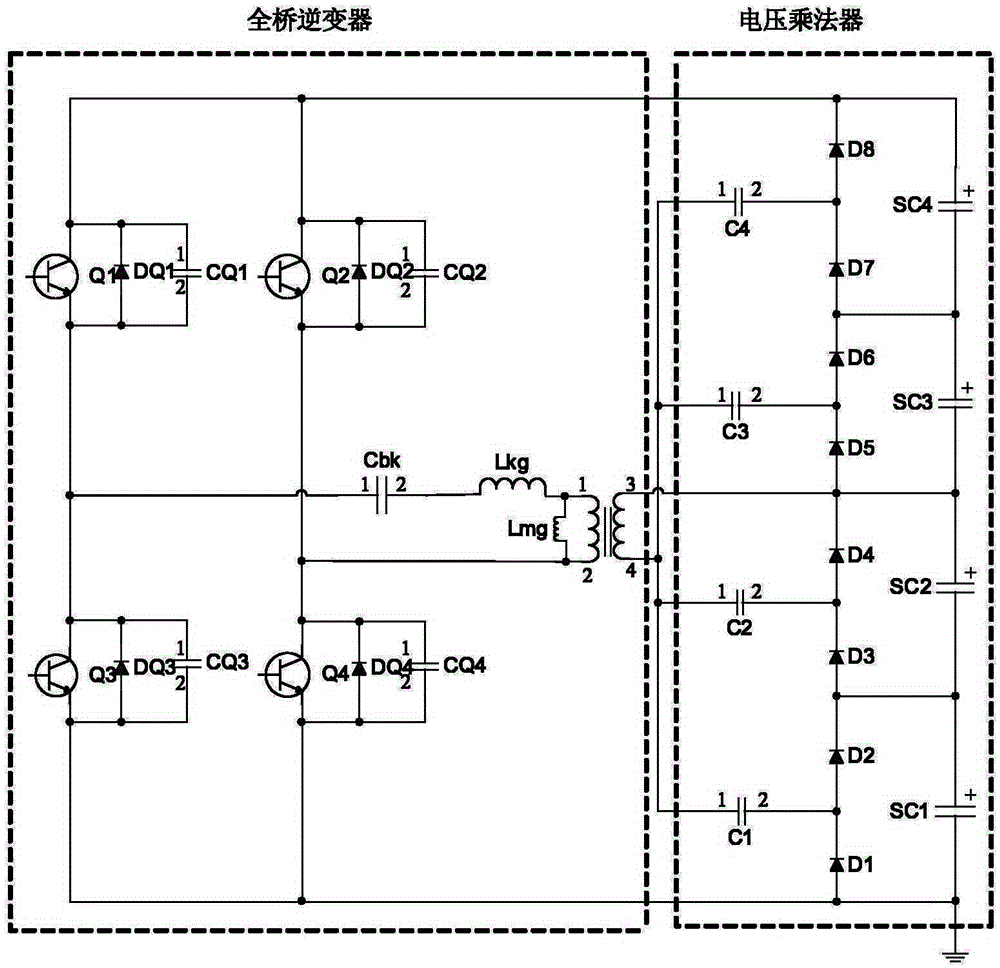

[0020] The invention can be divided into two functional blocks: a full bridge inverter and a voltage multiplier. The input of the full-bridge inverter is connected to the output of the voltage multiplier, so that the energy stored in the supercapacitor can circulate and flow, and all the supercapacitor voltages are automatically balanced during the energy circulation process. As shown in Figure 1(a) and Figure 1(b).

[0021] The full-bridge inverter consists of four fully-controlled devices Q1, Q2, Q3, Q4, four diodes DQ1, DQ2, DQ3, DQ4, five capacitors CQ1, CQ2, CQ3, CQ4, Cbk and a transformation ratio of 4: 1 Transformer, in which the fully controlled device can be a common N-channel PMOSFET or IGBT; the drain (or collector) of the fully controlled device Q1 is respectively connected to the cathodes of diodes DQ1 and DQ2, and the terminals of capacitors CQ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com