Capacitance voltage division type direct current voltage reduction technology

A technology of DC step-down and capacitive voltage division, which is applied in the direction of conversion equipment without intermediate conversion to AC

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

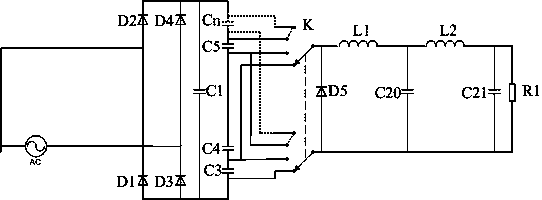

[0045] figure 2 The invention is further described as a specific implementation manner of the capacitive voltage-dividing DC step-down technology. It should be noted, figure 2 It is only one of the specific implementation modes, and the present invention also has other specific implementation modes.

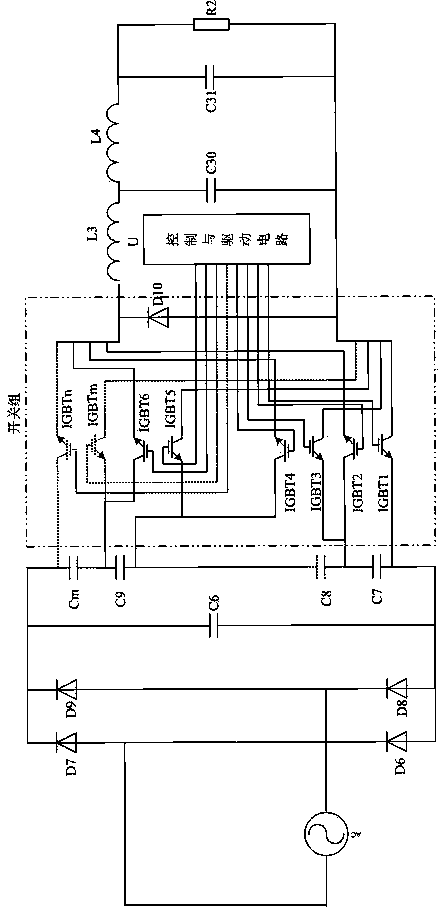

[0046] exist figure 2 In, use IGBT to form a switch group to realize figure 1 The function of the switch K in the switch, and the control and drive of the IGBT are constructed using corresponding hardware and software as required.

[0047] exist figure 2 , the power supplies power to the capacitor C6 and the series capacitor branch through the rectifier circuit. When the series capacitor branch is fully charged, the switches of the switch group are turned on and off in sequence through the control signal, so that each capacitor in the series capacitor branch discharges the low voltage circuit in turn, thereby realizing the power from the high voltage side to the low vol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com