Soil vapor extraction volatile organic pollutant tail gas clarification system

A volatile organic and exhaust gas purification technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of reduced removal efficiency and difficulty, and achieve the goal of overcoming poor effects and increasing the probability of photocatalytic degradation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to have a deeper understanding of the present invention, a specific embodiment is listed below, and the present invention is further described in detail in conjunction with the accompanying drawings.

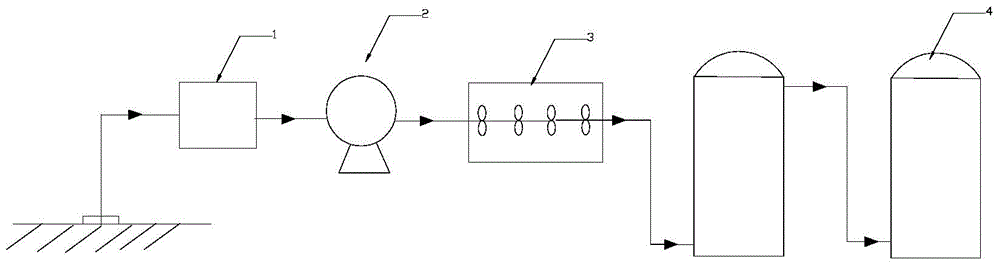

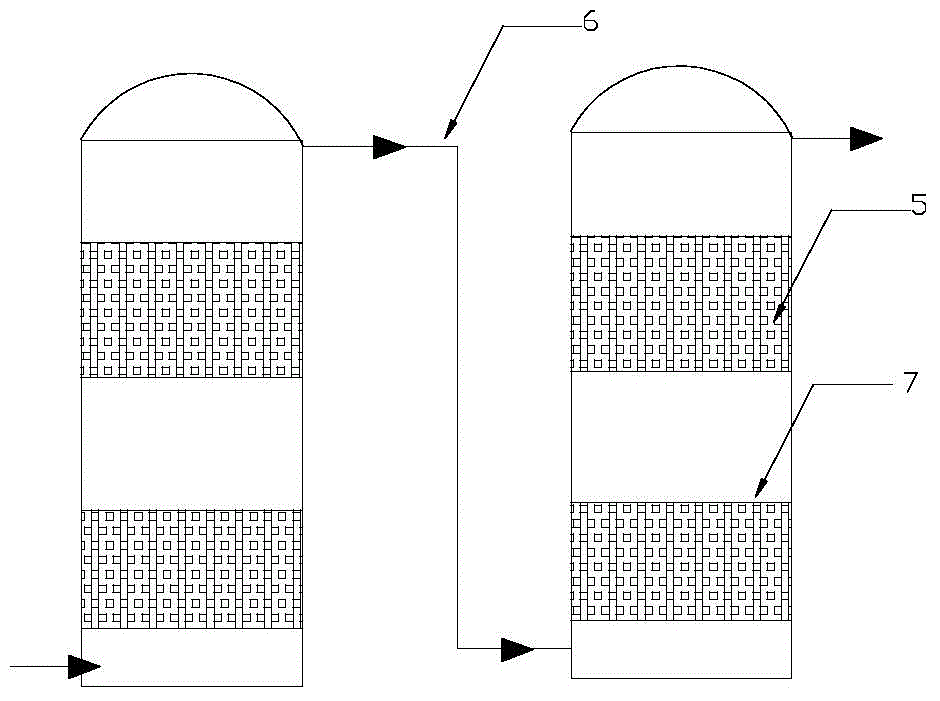

[0024] see figure 1 , a soil gas-phase extraction volatile organic pollutant tail gas purification system and device, its composition includes: its composition includes a gas-liquid separator 1, a vacuum pump 2, a solid-mounted photocatalytic pretreatment reactor 3 and a 2-stage bio-carbon purification Tower 4.

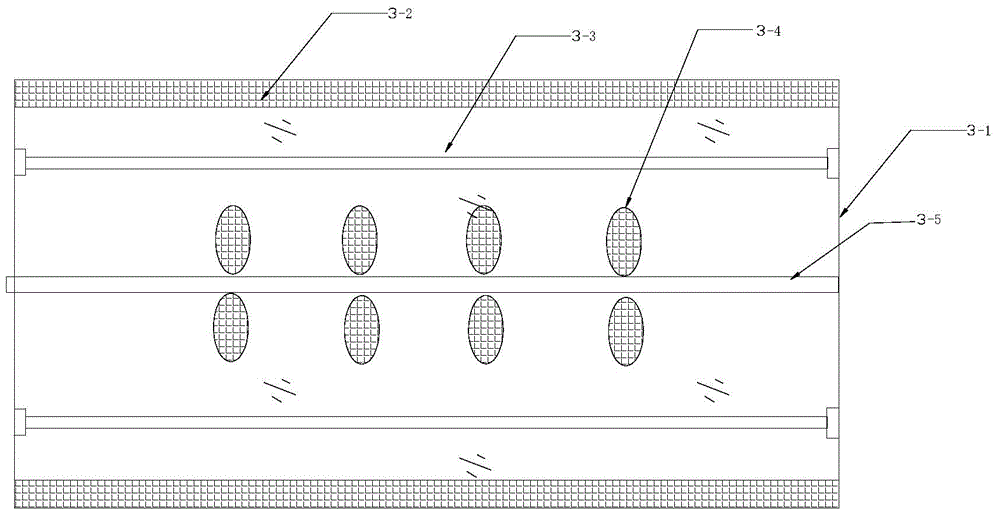

[0025] figure 2 It is a schematic diagram of the structure of the photocatalyst catalytic pretreatment reactor in an example of the present invention. The photocatalyst catalytic reactor is a closed shell, and an ultraviolet light source and a propeller type agitator 3-5 are installed in the shell. The ultraviolet light source used in the ultraviolet light source It is the ultraviolet light in the band between 185nm-172nm, and the ultraviolet light so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com