Converter vanadium extraction process of low silicon low temperature vanadium-containing molten iron

A low-temperature, molten iron technology, applied in the manufacture of converters, etc., can solve problems such as weak stirring ability, difficult temperature control, and application effects that need further verification and improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

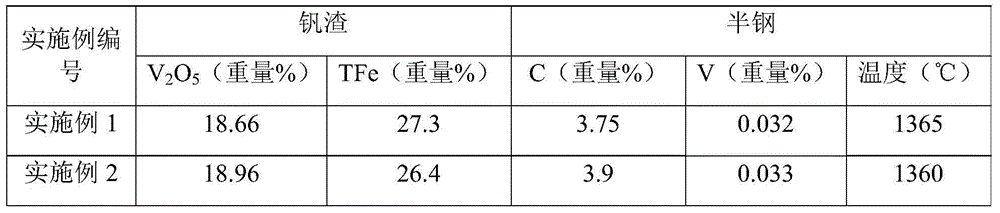

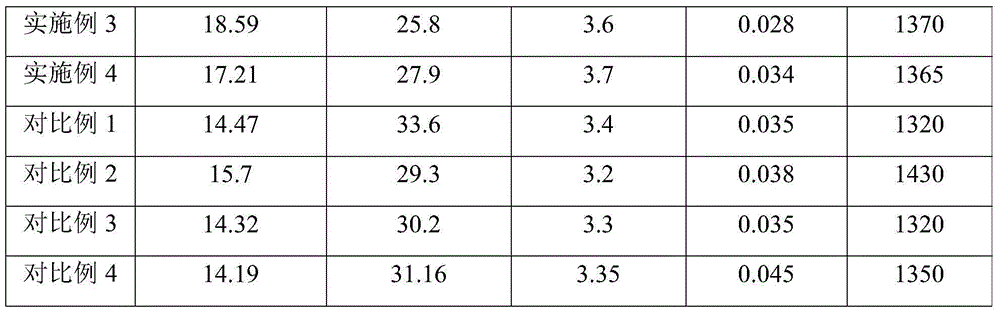

Embodiment 1

[0032]Put 140t of low-silicon and low-temperature vanadium-containing molten iron into the vanadium-extracting converter. The low-silicon and low-temperature vanadium-containing molten iron contains 4.55% by weight of C, 0.05% by weight of Si, 0.29% by weight of Mn, 0.26% by weight of Ti, and 0.25% by weight of Ti. % of V, 0.064% by weight of P and 0.005% by weight of S, and the rest is Fe. The temperature of the low-silicon and low-temperature vanadium-containing molten iron entering the furnace is 1225°C. Through the oxygen lance (when the oxygen blowing volume is 88%, the control gun position is 1.7m) Blow oxygen into the converter for blowing, the total amount of oxygen blowing is 11.8m 3 / t Low-silicon and low-temperature vanadium-containing molten iron, the temperature at the end of blowing is controlled at 1365°C (the blowing time is 5 minutes). When blowing 1min, add coolant (containing 30% by weight of Fe 2 o 3 , 45 wt% FeO, 5 wt% SiO 2 , 2% by weight Al 2 o 3 ...

Embodiment 2

[0034] Put 140t of low-silicon and low-temperature vanadium-containing molten iron into the vanadium-extracting converter. The low-silicon and low-temperature vanadium-containing molten iron contains 4.45% by weight of C, 0.1% by weight of Si, 0.26% by weight of Mn, 0.27% by weight of Ti, and 0.28% by weight of Ti. % of V, 0.068% by weight of P and 0.006% by weight of S, and the rest is Fe. The temperature of the low-silicon and low-temperature vanadium-containing molten iron entering the furnace is 1250°C. Through the oxygen lance (when the oxygen blowing volume is less than 10%, the control gun position is 1.8m; when the oxygen blowing volume is 10-88%, the control gun position is 2.1m; when the oxygen blowing volume is >88%, the control gun position is 1.6m ) blowing oxygen into the converter for blowing, the total amount of oxygen blowing is 12.8m 3 / t Low-silicon and low-temperature vanadium-containing molten iron, the temperature at the end of blowing is controlled at 1...

Embodiment 3

[0036] Put 140t of low-silicon and low-temperature vanadium-containing molten iron into the vanadium-extracting converter. The low-silicon and low-temperature vanadium-containing molten iron contains 4.45% by weight of C, 0.035% by weight of Si, 0.30% by weight of Mn, 0.28% by weight of Ti, and 0.29% by weight of Ti. % of V, 0.069% by weight of P and 0.005% by weight of S, and the rest is Fe. The temperature of the low-silicon and low-temperature vanadium-containing molten iron entering the furnace is 1205°C. Through the oxygen lance (when the oxygen blowing volume is 88%, the control gun position is 1.7m ) blowing oxygen into the converter for blowing, the total amount of oxygen blowing is 10.9m 3 / t Low-silicon and low-temperature vanadium-containing molten iron, the temperature at the end of blowing is controlled at 1370°C (the blowing time is 4.8min). When blowing 1min, add coolant (containing 45% by weight of Fe 2 o 3 , 30 wt% FeO, 7 wt% SiO 2 , 3% by weight Al 2 o ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com