Construction method for bored pile

A technology of bored piles and construction methods, applied in sheet pile wall, foundation structure engineering, construction and other directions, can solve the problems of high production cost, environmental pollution, large proportion of mud, etc., to simplify construction steps, reduce production costs, The effect of reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A construction method for bored piles, comprising the steps of pre-construction preparation, drilling construction, implanting wall protection bags, hoisting reinforcement cages and pouring concrete;

[0024] (1) Preparation before construction: Locate the position of the bored pile, clear the obstacles within the influence range of the pile foundation construction, bury the steel casing, the wall thickness of the steel casing is 5mm, and the length is 5m. The depth of the casing is about 40cm deep, and the diameter of the casing is 30cm larger than the diameter of the preset borehole;

[0025] (2) Drilling construction: install the drilling rig, such as figure 1 As shown, the pile hole 1 of the cast-in-place pile is drilled;

[0026] (3) Insert the retaining bag: move the drilling rig out of pile hole 1, such as figure 2 As shown, a cylindrical wall protection bag 2 with a diameter equal to the inner diameter of the pile hole 1 is implanted in the pile hole 1, the w...

Embodiment 2

[0031] (1) Preparation before construction: Locate the position of the bored pile, clear the obstacles within the influence range of the pile foundation construction, bury the steel casing, the wall thickness of the steel casing is 16mm, and the length is 8m. The depth of the casing is about 60cm deep, and the diameter of the casing is 50cm larger than the diameter of the preset borehole;

[0032] (2) Drilling construction: install the drilling rig and drill the pile holes of the cast-in-place piles;

[0033] (3) Inserting the retaining bag: move the drilling rig out of the pile hole, implant a cylindrical retaining bag with a diameter equal to the inner diameter of the pile hole in the pile hole, seal the retaining bag, continue to inflate the retaining bag, and fully expand the retaining bag, so that The retaining bag is attached to the inner wall of the pile hole;

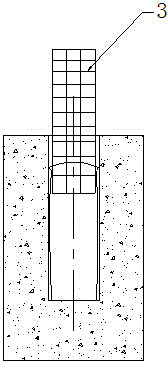

[0034] (4) Hoisting the reinforcement cage: open the sealed wall protection bag, hang the reinforcement cage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com