A multi-layer composite anti-eccentric wear continuous sucker rod and its preparation device and method

A multi-layer composite and device preparation technology, applied in drill pipes, layered products, earth-moving drilling, etc., can solve the problem of low hardness of thermoplastic wear-resistant layer, poor temperature resistance and wear resistance, and unlimited left and right directions. Position and other problems, to achieve the effect of increasing radial strength and axial compressive strength, excellent corrosion resistance and eccentric wear resistance, and improving continuous stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

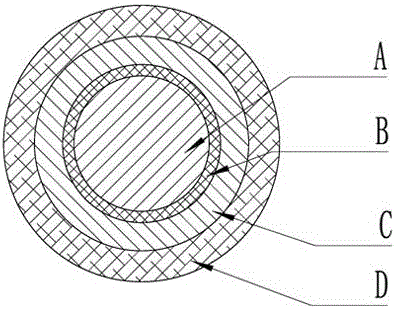

[0040] The preparation method of multi-layer composite anti-eccentric wear continuous sucker rod, the longitudinal fiber A of the inner layer is carbon fiber, the longitudinal fiber C of the outer layer is high-strength glass fiber, and the middle winding layer B of the inner and outer layer is high-strength glass fiber, and its preparation method includes the following step:

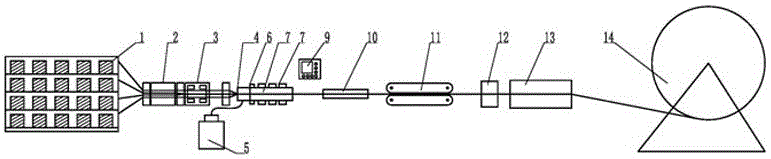

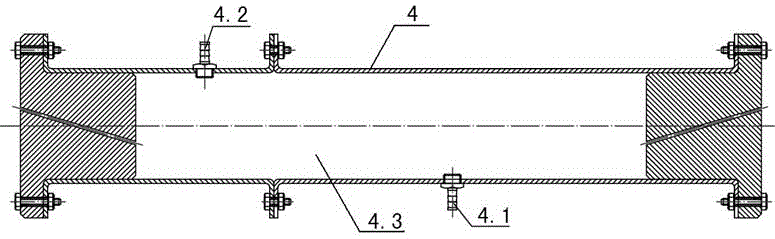

[0041] The multi-bundle carbon fiber filaments in the inner layer enter the surface treatment furnace through the wire hole of the wire rack. The furnace temperature is between 80 and 150 °C, the pulling speed is between 0.08 and 1.5 m / min, and the passing time is 1.0 to 12.5 minutes , the carbon fiber after heat treatment, after the wrapping layer of glass fiber, enters the injection mold together with the wrapping layer and the outer layer of high-strength glass fiber, and the injection mold is filled with the resin glue injected by the injection machine. The ratio of the resin glue is polyol: Isocyan...

Embodiment 2

[0043]The preparation method of fiber-reinforced composite anti-eccentric wear continuous sucker rod, the inner layer longitudinal fiber A and the outer layer longitudinal fiber C are high-strength glass fibers, and the middle winding layer B uses high-strength glass fiber. The preparation method comprises the following steps:

[0044] The traction speed is 0.2 m / min, and the injection resin is changed to epoxy resin, wherein the parts by weight of epoxy resin E-51: methyltetrahydrophthalic anhydride: DMP-30: zinc stearate are 100:85:2.0:1 , the pultrusion die is heated in two stages, the temperature is 120°C and 160°C; the length of the die is 1000mm, and the formed sucker rod is treated by a post-curing treatment furnace with a temperature of 160°C and a length of 3m; after cooling, it is continuously sprayed with thermosetting resin A fluorocarbon coating with a thickness of 2 mm was sprayed as a wear-resistant layer. After sufficient curing, the fiber-reinforced composite c...

Embodiment 3

[0046] The preparation method of the preferred fiber-reinforced composite anti-eccentric wear continuous sucker rod, the inner layer longitudinal fiber A and the outer layer longitudinal fiber C are basalt fibers, and the middle winding layer B is also basalt fiber, and the preparation method comprises the following steps:

[0047] The furnace temperature for fiber heat treatment is 120°C, the traction speed is 0.38 m / min, and the injection resin is changed to vinyl ester resin, wherein the weight parts of Atlac 430: MEKP: BPO: zinc stearate are 100: 1.5: 1.5: 1 , the mold is heated in three stages, the temperature is 95°C, 115°C, and 145°C; the formed sucker rod is processed by a post-curing furnace with a temperature of 140°C and a length of 3m; after cooling, it is continuously extruded by thermosetting resin spraying equipment. 10mm modified epoxy resin is used as the wear-resistant layer. After sufficient cooling, the fiber reinforced composite continuous sucker rod with w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com