Liquid-hydrogen temperature zone vibration test heat insulation method for cold-helium pressurization system of rocket tank

A technology of pressurization system and vibration test, which is applied in vibration test, test of mechanical parts, test of machine/structural parts, etc., to achieve good thermal insulation effect, good protection effect, simplified thermal insulation construction procedure and the effect of required tooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

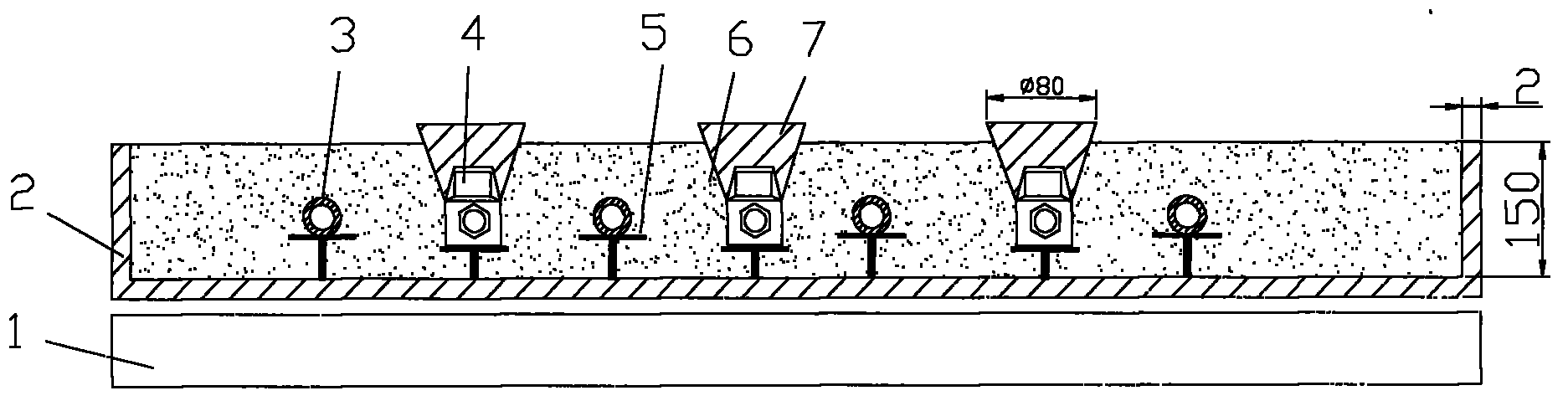

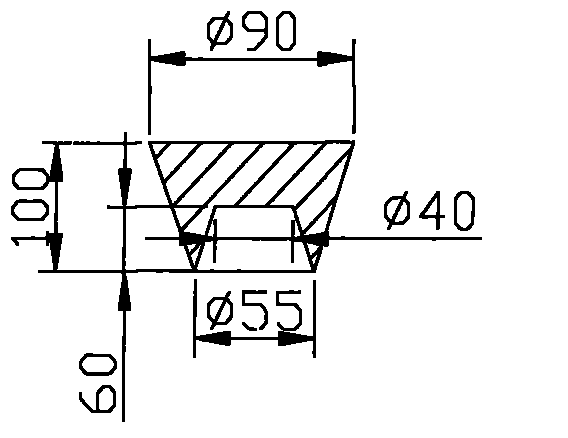

[0014] Such as figure 1 As shown, the main devices and materials used in the present invention are: a stainless steel box 2, a supporting fastener 5, a polyurethane insulation material 6, and an electromagnet protective cover 7. The stainless steel box is made of 2mm thick stainless steel plate. The bottom area is 1000mm×800mm. The size is the same as the horizontal sliding table 1 plane of the vibrating table. The bottom surface is provided with installation through holes corresponding to the horizontal sliding table 1 plane. The height of the four sides is 150mm; the lower end of the support fastener 5 is welded to the inner bottom surface of the stainless steel box 2, and its height ensures that the distance between the center of the cold helium pipeline 3 and the cold helium solenoid valve 4 and the inner bottom surface of the stainless steel box 2 is 60mm; the appearance of the electromagnet protective cover 7 is inverted Round table, such as figure 2 As shown, there are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com