Non-addictive pure grain health black ice cream and production method thereof

An additive-free, ice cream technology, applied in frozen desserts, food science, applications, etc., can solve the problems of low dietary fiber, high energy, low protein, etc., and achieve the effect of good fluidity, high nutritional value, and optimized sensory quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

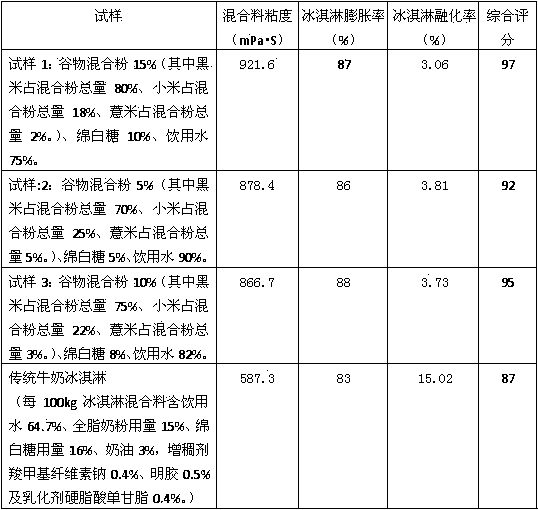

Examples

Embodiment 1

[0022] (1) Small molecule anti-retrogradation treatment of raw materials of black rice, millet and barley

[0023] Black rice, millet, and barley grains are crushed into powders with a particle size of 120 mesh, added with drinking water to adjust the water content to 40%, sealed and anaerobic, soaked at 30°C for 30 minutes to make the plant fibers stretch and loose, and extruded at one time with a single screw respectively. Gelatinization and granulation, the extrusion temperature is 175°C, and the particles with a particle size of 6mm are obtained, and the microwave small molecule anti-retrogradation treatment is carried out immediately, the microwave frequency is 2450MHz, and the microwave energy supply is 0.5kw / kg·h. The test material does not contain macromolecular starch, the reaction of iodine is brownish yellow, and there is no retrogradation of starch. Then be pulverized into particle size and be the small molecule grain powder of 160 purpose for subsequent use;

[002...

Embodiment 2

[0031] (1) Small molecule anti-retrogradation treatment of raw materials of black rice, millet and barley

[0032] Black rice, millet, and barley are crushed into 140 meshes, adding drinking water to adjust the water content to 50%, airtight and anaerobic, and infiltrating at 35°C for 40 minutes to make the plant fibers stretch and loose. Single-screw extrusion, gelatinization and granulation , the extrusion temperature is 180°C, and the particles with a particle size of 10mm are obtained, and the microwave small molecule anti-retrogradation treatment is carried out immediately, the microwave frequency is 2450MHz, and the microwave energy supply is 2kw / kg·h. After the treatment, the water content of the material is 6%. Molecular starch, iodine reaction is brownish yellow, no starch retrogradation phenomenon, and then crushed into small molecular grain flour with a particle size of 200 mesh for later use;

[0033] (2) Flavor optimization

[0034] Grain flours treated with smal...

Embodiment 3

[0040] (1) Small molecule anti-retrogradation treatment of raw materials of black rice, millet and barley

[0041] Black rice, millet, and barley are crushed into 120 meshes respectively, adding drinking water to adjust the water content to 45%, airtight and anaerobic, soaking at 32°C for 35 minutes to make the plant fibers stretch and loose, single-screw extrusion, gelatinization and granulation , the extrusion temperature was 178°C, and the particles with a particle size of 8mm were obtained. They were immediately subjected to microwave small molecule anti-retrogradation treatment. The microwave frequency was 2450MHz, and the microwave energy supply was 1.5kw / kg·h. Macromolecular starch, iodine reaction is brownish yellow, no starch retrogradation phenomenon. Then be pulverized into particle size respectively and be the small molecular grain flour of 180 purpose for subsequent use;

[0042] (2) Flavor optimization

[0043] Grain flour treated with small molecule anti-retro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com