Preparation process of compound glabrous greenbrier rhizome granules

A preparation process, the technology of Smilax smilax, applied in the field of preparation of compound Smilax smilax granules, can solve the problems of poor repeatability of molding process, high cost, unreasonable design of water extraction process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Take by weighing 45 parts of raw material Smilax smilax, 15 parts of Achyranthes bidentata, 15 parts of fennel, 15 parts of Wang Buliuxing, and 15 parts of Arrowhead mushroom, and prepare compound Smilax smilax granules according to the following process steps:

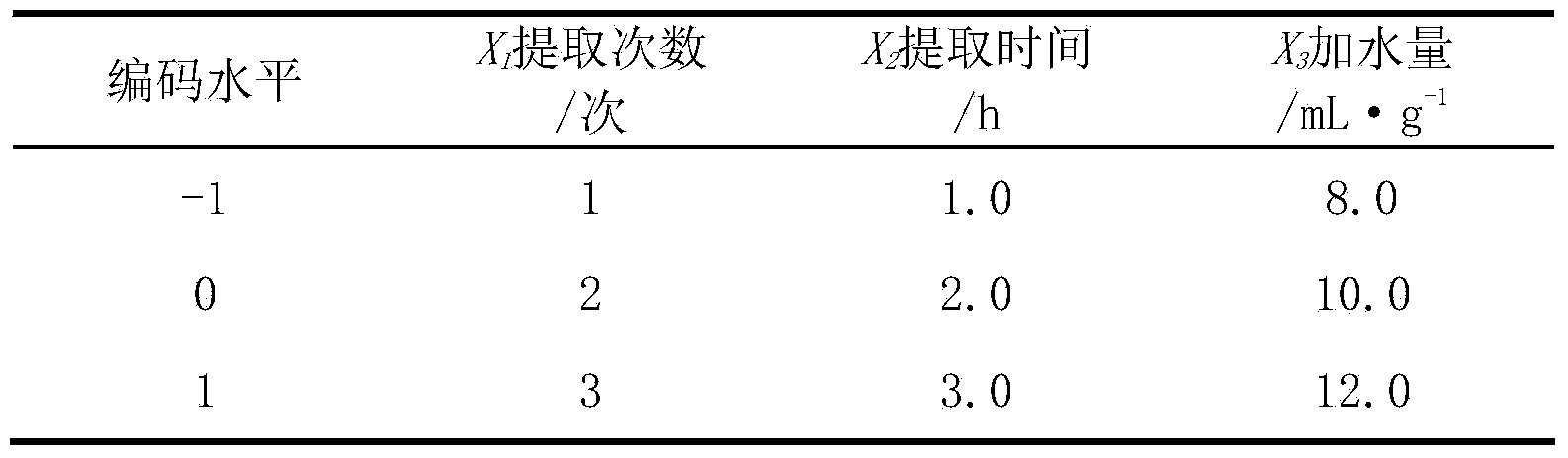

[0067] (1) Water extraction: take by weight 45 parts of raw material Smilax tuckahoe, 15 parts of Achyranthes bidentata, 15 parts of fennel, 15 parts of vaccinia, 15 parts of Arrowhead mushroom, add 8 times of water and soak for 30 minutes, Boil for 1 hour, pass through three layers of gauze to obtain water extract;

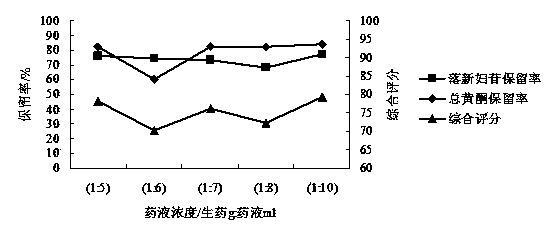

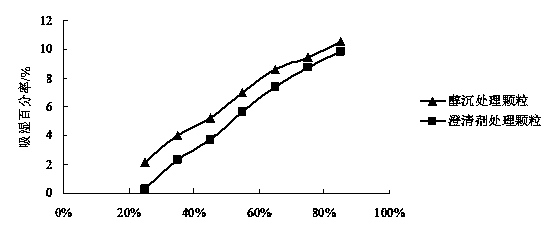

[0068] (2) Clarification: Evaporate and concentrate the water extract prepared in step B to a concentration of 1:5 (crude drug g / medicine liquid mL), stir at 50°C (100r min -1 ) condition, add 5mL of viscose solution of A component of ZTC1+1-Ⅱ clarifier with a concentration of 1%, and then stir once every 30min or so; after 2h, stir at 60°C (100r·min Add 2.5mL of B-component viscose liquid with a...

Embodiment 2

[0071] Take by weighing 45 parts of raw material Smilax smilax, 15 parts of Achyranthes bidentata, 15 parts of fennel, 15 parts of Wang Buliuxing, and 15 parts of Arrowhead mushroom, and prepare compound Smilax smilax granules according to the following process steps:

[0072] (1) Water extraction: take by weight 45 parts of raw material Smilax tuckahoe, 15 parts of Achyranthes bidentata, 15 parts of fennel, 15 parts of vaccinia, 15 parts of Arrowhead mushroom, add 10 times of water and soak for 30 minutes, Boil for 2 hours, pass through three layers of gauze, add 10 times more water to decoct twice, filter, and combine the filtrate three times;

[0073] (2) Clarification: Evaporate and concentrate the water extract prepared in step B to a concentration of 1:8 (crude drug g / medicine liquid mL), stir at 70°C (100r min -1 ) conditions, add 30mL of viscose solution of A component of ZTC1+1-Ⅱ clarifier with a concentration of 1%, and then stir once every 30min; Next, add 15mL of ...

Embodiment 3

[0076] Take by weighing 45 parts of raw material Smilax smilax, 15 parts of Achyranthes bidentata, 15 parts of fennel, 15 parts of Wang Buliuxing, and 15 parts of Arrowhead mushroom, and prepare compound Smilax smilax granules according to the following process steps:

[0077] (1) Water extraction: take by weight 45 parts of raw material Smilax tuckahoe, 15 parts of Achyranthes bidentata, 15 parts of fennel, 15 parts of vaccinia, 15 parts of Arrowhead mushroom, add 12 times of water and soak for 30 minutes, Boil for 2 hours, pass through three layers of gauze, add 12 times of water to decoct twice, filter, and combine the filtrate three times;

[0078] (2) Clarification: Evaporate and concentrate the water extract obtained in step B to a concentration of 1:12 (crude drug g / medicine liquid mL), stir at 90°C (100r min -1 ) under the condition, add 50mL of viscose solution of A component of ZTC1+1-Ⅱ clarifier with a concentration of 1%, and then stir once every 30min or so; after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com