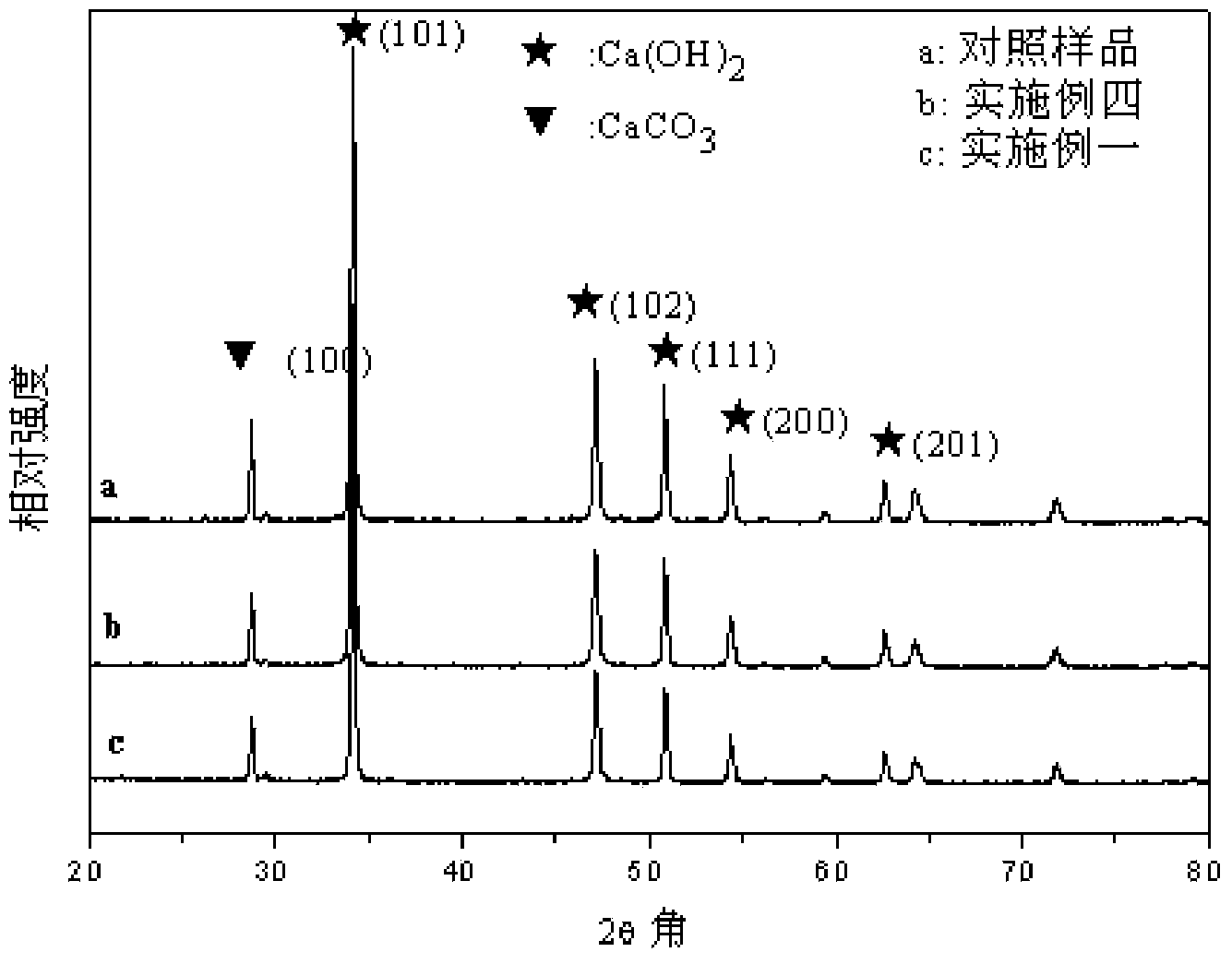

Preparation method of calcium hydroxide nano particles with high adsorption activity

A technology of calcium hydroxide and nanoparticles, which is applied in the field of preparation of calcium oxide nanoparticles, and can solve problems such as powder instability and low specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1. Weigh 22.2g CaCl 2 , put into a 250ml three-neck bottle, add 80ml deionized water to dissolve, and stir with a magnetic stirrer;

[0019] 2. Weigh 0.47g of SDS into the three-necked bottle, stir to dissolve;

[0020] 3. Weigh 8.0g of NaOH and dissolve it in 20ml of deionized water, drop it into a three-necked bottle at a rate of 40ml / h, and stir for 0.5h.

[0021] 4. After the slurry obtained by the reaction was suction-filtered, it was washed twice with distilled water and then twice with ethanol, and finally the filter cake was vacuum-dried at 60°C for 24 hours.

Embodiment 2

[0023] 1. Weigh 22.2g CaCl 2 , put into a 250ml three-neck bottle, add 80ml deionized water to dissolve, and stir with a magnetic stirrer;

[0024] 2. Weigh 1.17g of SDS into the three-necked bottle, stir to dissolve;

[0025] 3. Weigh 8.0g NaOH and dissolve it in 20ml deionized water, drop it into the three-necked bottle at a rate of 40ml / h, and stir for 1.5h.

[0026] 4. After the slurry obtained by the reaction was suction-filtered, it was washed twice with distilled water and then twice with ethanol, and finally the filter cake was vacuum-dried at 60°C for 24 hours.

Embodiment 3

[0028] 1. Weigh 22.2g CaCl 2 , put into a 250ml three-neck bottle, add 80ml deionized water to dissolve, and stir with a magnetic stirrer;

[0029] 2. Weigh 2.34g of SDS into the three-necked bottle, stir to dissolve;

[0030] 3. Weigh 8.0g of NaOH and dissolve it in 20ml of deionized water, drop it into a three-necked bottle at a rate of 40ml / h, and stir for 2.5h.

[0031] 4. After the slurry obtained by the reaction was suction-filtered, it was washed twice with distilled water and then twice with ethanol, and finally the filter cake was vacuum-dried at 60°C for 24 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com