Zeolite perlite powder gel chitosan resin adsorbent and preparation method thereof, and purification and production method of hyaluronic acid

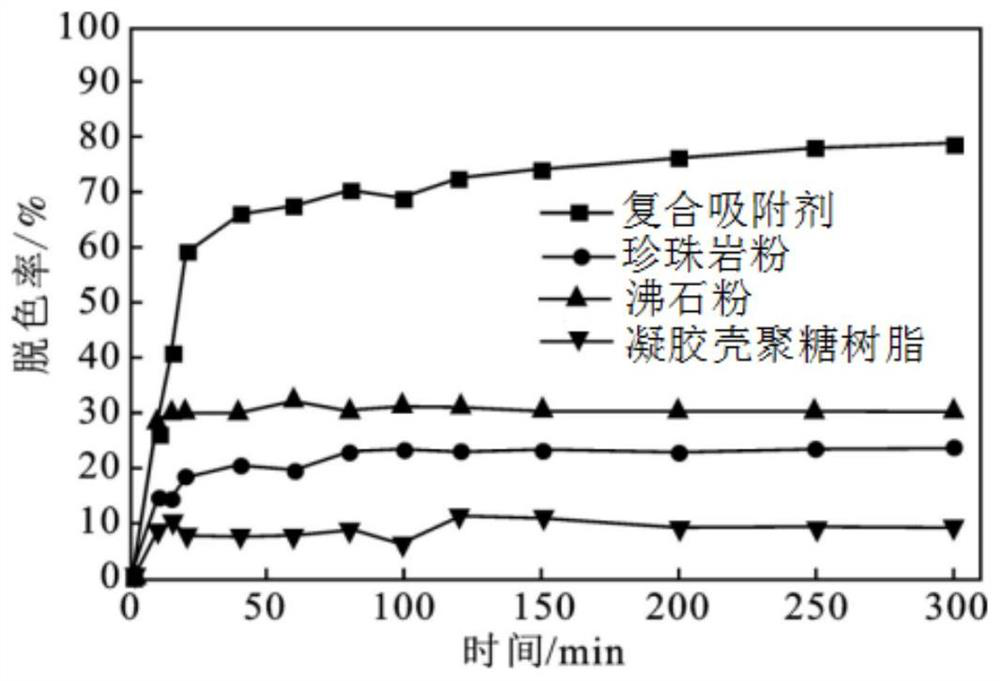

A technology of chitosan resin and perlite powder, which is applied in the direction of solid adsorbent liquid separation, separation methods, and other chemical processes, can solve the problems of cumbersome process and low removal rate of impurities, and achieve high processing efficiency and strong adsorption Miscellaneous ability, the effect of shortening the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

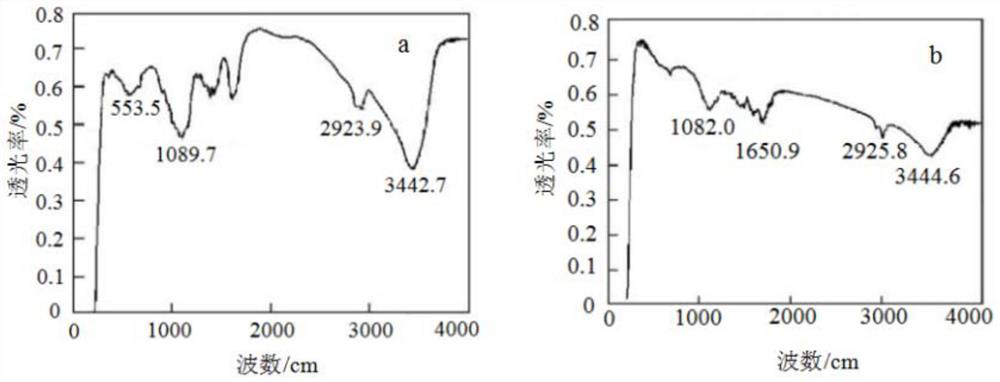

[0080] Yet chitosan also has some deficiencies: it is inconvenient to directly use chitosan as a material, and the scope of application is narrow, non-porous and easy to run off, so the present invention needs to make chitosan into gel chitosan sugar resin. Specifically, the preparation method of the gel chitosan resin includes the following steps: S11, dissolving chitosan in a dilute acid solution to obtain a chitosan dilute acid solution; S12, dissolving the metal hydroxide solution with a crosslinking agent Mix evenly to obtain a solidified solution; S13. Slowly add chitosan dilute acid solution to the solidified solution dropwise under stirring conditions, filter after the dropwise addition is completed, wash the wet resin obtained after filtering until it is neutral, and then decolorize. The resin is dried to obtain gel chitosan resin.

[0081] In step S11, specific examples of the dilute acid solution include but are not limited to: at least one of hydrochloric acid sol...

preparation example 1

[0123] This preparation example is used to illustrate the zeolite perlite powder gel chitosan resin adsorbent provided by the present invention and its preparation method.

[0124] (1) Preparation of gel chitosan resin:

[0125] S11. Prepare 1.5 L of a dilute hydrochloric acid solution with a concentration of 1% v / v, add 30 g of chitosan into the dilute hydrochloric acid solution and stir until dissolved to obtain a chitosan dilute acid solution.

[0126] S12. Add 200g of NaOH solid into 500mL of pure water and stir until dissolved to obtain an aqueous sodium hydroxide solution. After cooling, add 200mL of methanol solution and stir evenly to obtain a solidified solution for use.

[0127] S13. Slowly drip the chitosan dilute acid solution obtained in step S11 into the solidified solution obtained in step S12 under the condition of slow stirring with a syringe needle, stir and filter for 10 minutes after the addition is completed, wash the obtained wet resin with water until neut...

preparation example 2

[0132] This preparation example is used to illustrate the zeolite perlite powder gel chitosan resin adsorbent provided by the present invention and its preparation method.

[0133] (1) Preparation of gel chitosan resin:

[0134] S11. Prepare 2 L of dilute acetic acid solution with a concentration of 1% v / v, add 50 g of chitosan into the dilute acetic acid solution and stir until dissolved to obtain a dilute chitosan acid solution.

[0135] S12. Add 250g of NaOH solid into 1000mL of pure water and stir until dissolved to obtain an aqueous sodium hydroxide solution. After cooling, add 300mL of methanol solution and stir evenly to obtain a solidified solution for use.

[0136] S13. Slowly drip the chitosan dilute acid solution obtained in step S11 into the solidified solution obtained in step S12 under the condition of slow stirring with a syringe needle, stir and filter for 10 minutes after the addition is completed, wash the obtained wet resin with water until neutral, and then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com