A preparation method of biochar modified material for removing phosphorus in eutrophic water body

A technology of eutrophication and modified materials, which is applied in the direction of chemical instruments and methods, water pollutants, soil conditioning materials, etc., can solve the problems of high cost of modified biochar, influence of product application, complicated process, etc., and achieve good adsorption The effect of removal ability, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A method for preparing a biochar modified material for removing phosphorus in eutrophic water bodies, comprising the steps of:

[0020] Step 1. Wash the apricot shells with a particle size of 0.5-4 mm with clean water to remove impurities on the surface of the biochar, and air-dry them naturally. The washed biochar was pulverized and sieved to obtain biochar powder with a particle size of 150 μm.

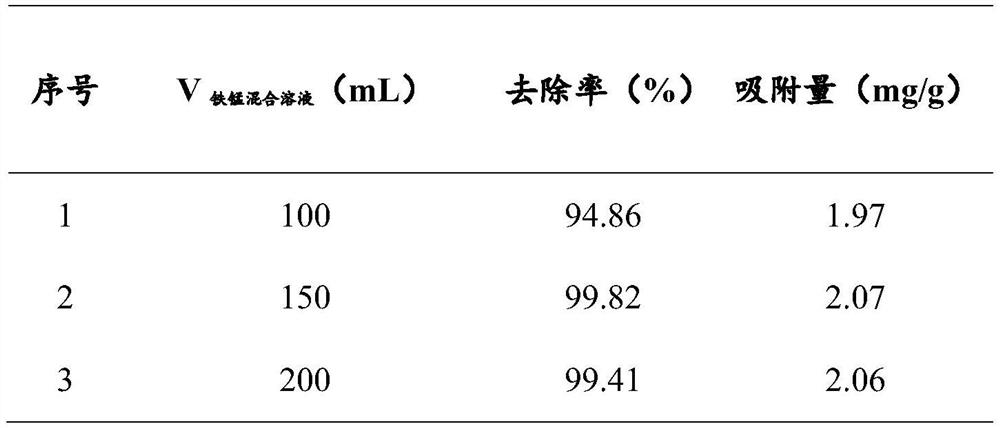

[0021] Step 2. Soak the biochar powder in the iron-manganese mixed solution with a volume of 100ml, and the FeCl in the iron-manganese mixed solution 3 and KMnO 4 The concentration is 0.05mol / L, the soaking time is 48h, after washing and filtering, the filtrate is colorless and neutral, and the pH is 7.0. Drying for 24 hours under the condition of 105° C. in a blast oven to obtain a composite metal-modified biochar functional material. It is measured that under the condition of different volumes of iron-manganese mixed solutions, the adsorption removal rate of 0.1g modifie...

Embodiment 2

[0025] A method for preparing a biochar modified material for removing phosphorus in eutrophic water bodies, comprising the steps of:

[0026] Step 1. Wash the walnut shells with a particle size of 0.5-4mm with clean water to remove impurities on the surface of the biochar, and then air-dry them naturally. The washed biochar was crushed and sieved to obtain biochar powder with a particle size of 150 μm.

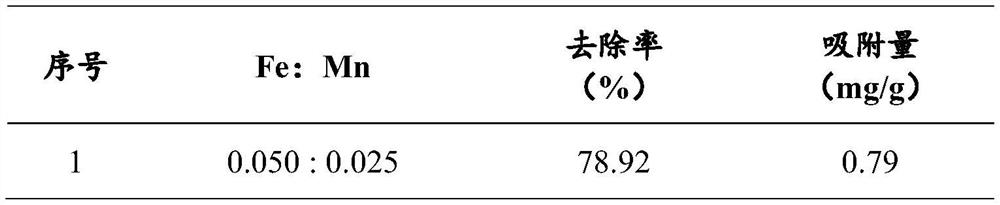

[0027] Step 2. Soak the biochar powder in 150mL of 0.050mol / L FeCl 3 ·6H 2 O and 0.025mol / LKMnO 4 In the mixed solution, the soaking time is 24h, and then filtered until the filtrate is colorless and neutral, with a pH of 7.5. Dry at 105° C. for 24 hours in a blast drying oven to obtain a composite metal-modified biochar functional material. It is measured that the adsorption and removal rate of the functional material to low-concentration phosphorus (0.5 mg / L) is 78.92%, and the adsorption capacity is 0.79 mg / g. The results are shown in Table 2.

[0028] Table 2 Phosph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com