Anechoic tile skin coating material and preparation method thereof

A coating material and technology of anechoic tiles, applied in the field of anechoic tile skin coating materials and its preparation, can solve problems such as small size of anechoic tiles, no patents and technology public reports, sealant cracking, etc. , to achieve the effects of improving the impact and pressure deformation resistance of the surface of the anechoic tile, reducing cracking and falling off, and reducing water friction resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

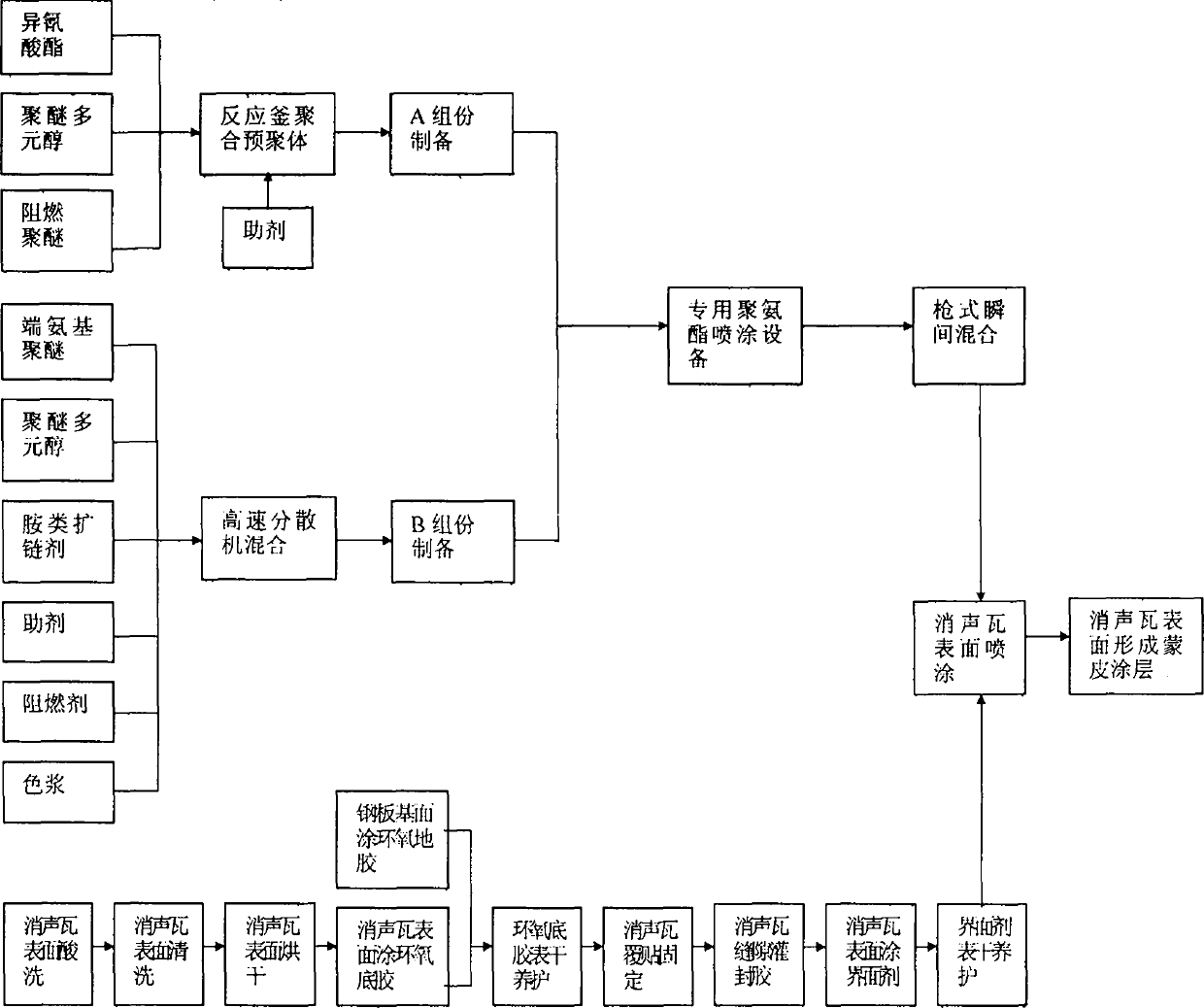

Method used

Image

Examples

Embodiment 1

[0027] The formula of the skin coating polyurethane material used in Example 1 of the patent of the present invention:

[0028] A component material formula Weight parts wt% B component material formula Weight parts wt% MDI isocyanate46 Amine chain extender E-10016 Polyether polyol N-22030 Amine chain extender E-3004 Flame retardant polyether OP-10016 Amine ether D-200040 Propylene carbonate8 Polyether polyol N21015 Yellow pulp5 Viscosity reducer, antioxidant1.5 Compound organic bismuth organic zinc1.5 Flame retardant OP-56017 total100 total100 Isocyanate content16.4% Mixed amine value15.8%

[0029] Preparation of component A of skin-coated polyurethane material: prepolymerize 46 parts of MDI isocyanate, 30 parts of polyol polyether N-220, and 16 parts of flame-retardant polyether OP-100 by dripping in a 500-liter reactor. Drop the temperature at 60~70℃, keep the temperature for 2~3 hours, then add 8 parts of propylene carbonate and stir together for 0.5 hours...

Embodiment 2

[0046] The entire implementation process of Example 2 is the same as that of Example 1, and will not be described; only the material formula is somewhat different, and the material performance test data is also somewhat different, which are listed in the following table.

[0047] The formula of the polyurethane skin coating material used in Example 2 of the patent of the present invention:

[0048] A component material formula Weight parts wt% B component material formula Weight parts wt% TDI-100 isocyanate50 Amine chain extender E-10022 Polyether polyol N-21033 Amine chain extender WH-62009 Flame retardant polyether OP-10012 Amine ether D-200032 Propylene carbonate5 Polyether polyol N21012 Polyurethane gray paste5 Antioxidant, light stabilizer3.2 Catalyst Organic Bismuth1.8 Flame retardant OP-550 15 total100 total100 Isocyanate content16.8% Mixed amine value16.2%

[0049] Preparation of component A of polyurethane skin coating material: prepolymerize 50 parts o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com