Rapid combustion, purification and regeneration device for black smoke and exhaust gas discharged by vehicles

A rapid combustion and processing device technology, applied in the direction of exhaust devices, mufflers, engine components, etc., can solve the problems of not fast enough exhaust heat removal, easy flameout, incomplete combustion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032]The specific implementation of the present invention will be described in more detail below in conjunction with the drawings and component symbols, so that those skilled in the art can implement it after studying this specification.

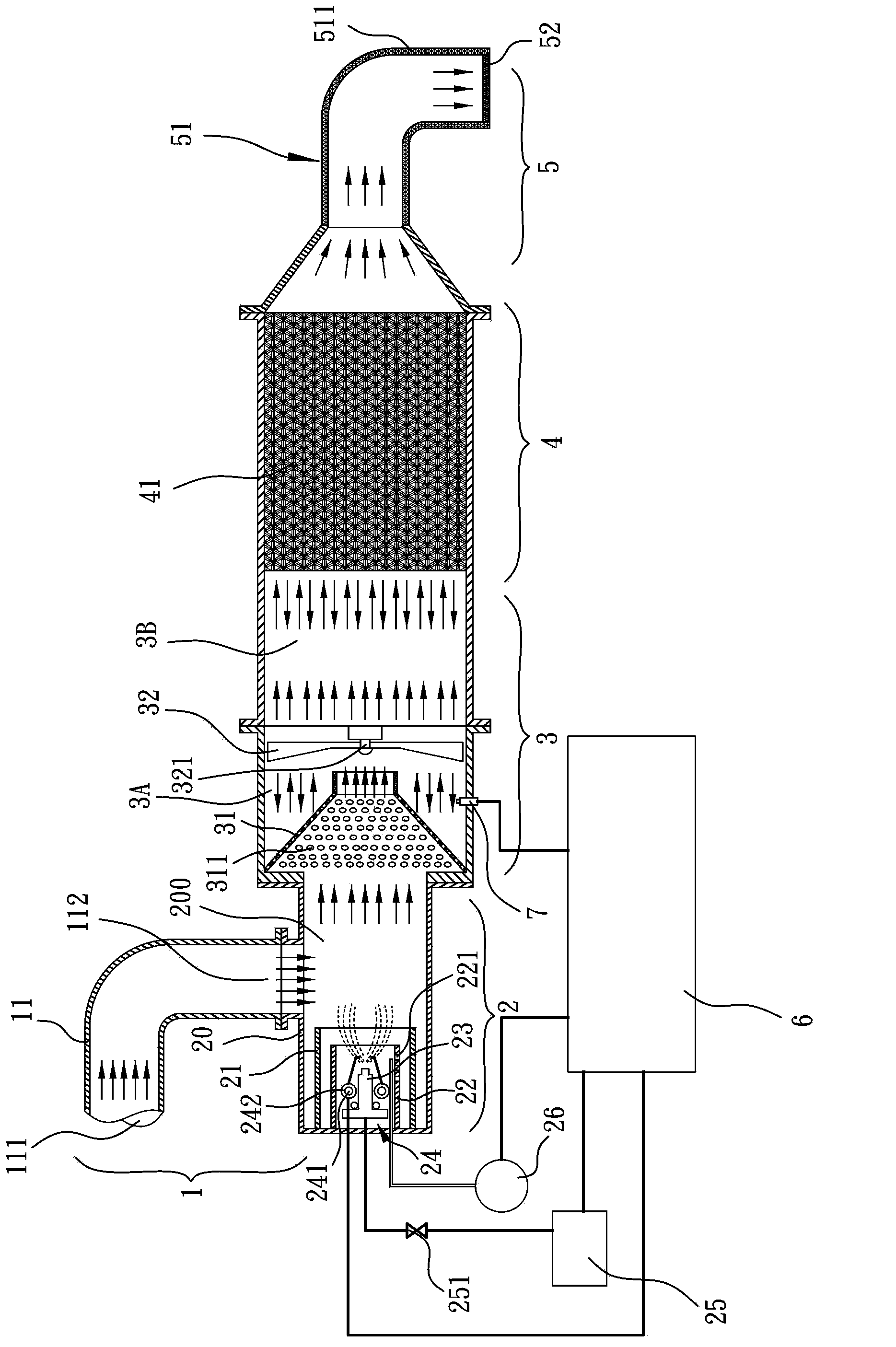

[0033] Such as figure 1 As shown, the vehicle exhaust black smoke exhaust gas rapid combustion purification regeneration treatment device provided by the present invention includes an air intake unit 1, a combustion unit 2, a buffer delay unit 3, a filter unit 4, and a discharge unit connected in sequence 5 and an automatic control unit 6; wherein, the air intake unit 1 has an exhaust pipe 11 whose two ends are respectively an air intake end 111 and an air outlet end 112, and the air intake end 111 is connected to an exhaust gas outlet of an engine (not shown in the figure show).

[0034] The combustion unit 2 includes an outer tube body 20 with a combustion chamber 200 inside, the side wall of the outer tube body 20 is connected to the ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com