Backlight module based on quantum dot light guide plate

A technology of backlight module and light guide plate, which is applied to optical elements, point light sources, optics and other directions for changing the spectral characteristics of emitted light, can solve the problems of low temperature, low light transmittance and large amount of quantum dots, etc. Achieve the effect of good heat dissipation, wide color gamut and high light efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

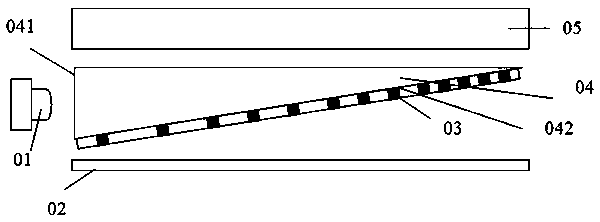

[0026] refer to figure 1 , is a schematic diagram of the first embodiment of the backlight module provided by the present invention. The backlight module includes a blue light source 01 , a light guide plate 04 , a reflection sheet 02 disposed below the light guide plate 04 , and an optical module 05 disposed above the light guide plate 04 . The blue light source 01 is located at the side of the light guide plate 04 .

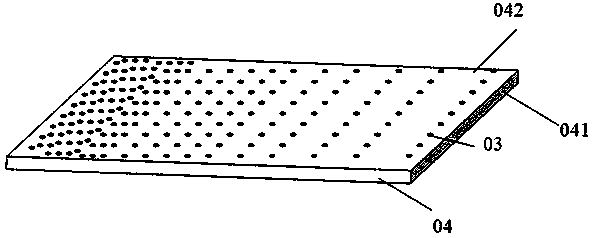

[0027] The light guide plate 04 has an upper surface 041 and a lower surface 042, and the lower surface 042 has light guide dots 03 distributed thereon. The light guide dots 03 are uniformly circular, with a diameter between 0.02 mm and 1 mm. The light guide dots 03 are distributed from dense to sparse on the lower surface 042 of the light guide plate, and the distribution density is between 2.5% and 76%. Use light simulation software to regulate the distribution of light guide points. According to the relative positional relationship between the light guide ...

Embodiment example 2

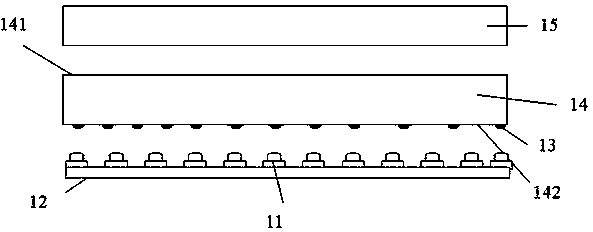

[0033] refer to image 3 , is a schematic diagram of the second embodiment of the backlight module provided by the present invention. The backlight module includes a blue light source array 11 , a light guide plate 14 , a reflection sheet 12 disposed below the light guide plate 14 , and an optical module 15 disposed above the light guide plate 14 . The blue light source array 11 is located under the light guide plate 14 .

[0034] The light guide plate 14 has an upper surface 141 and a lower surface 142 , and light guide dots 13 are distributed on the lower surface 142 . The light guide dots 13 are uniformly circular, with a diameter between 0.02 mm and 1 mm. The light guide dots 13 are distributed from dense to sparse arrays on the lower surface 142 of the light guide plate, and the distribution density is between 2.5% and 76%. between. Use light simulation software to regulate the distribution of light guide points. According to the relative positional relationship betwee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com