Moderate temperature straight all-glass vacuum heat collecting tube

A vacuum heat collecting tube and straight-through technology, which is applied in the field of solar heat utilization, can solve the problems of not being able to effectively compensate for large differences in expansion, low working temperature, and inconvenient connection in series, so as to reduce the difficulty of sealing and the failure rate. The effect of reducing the connection difficulty and improving the reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

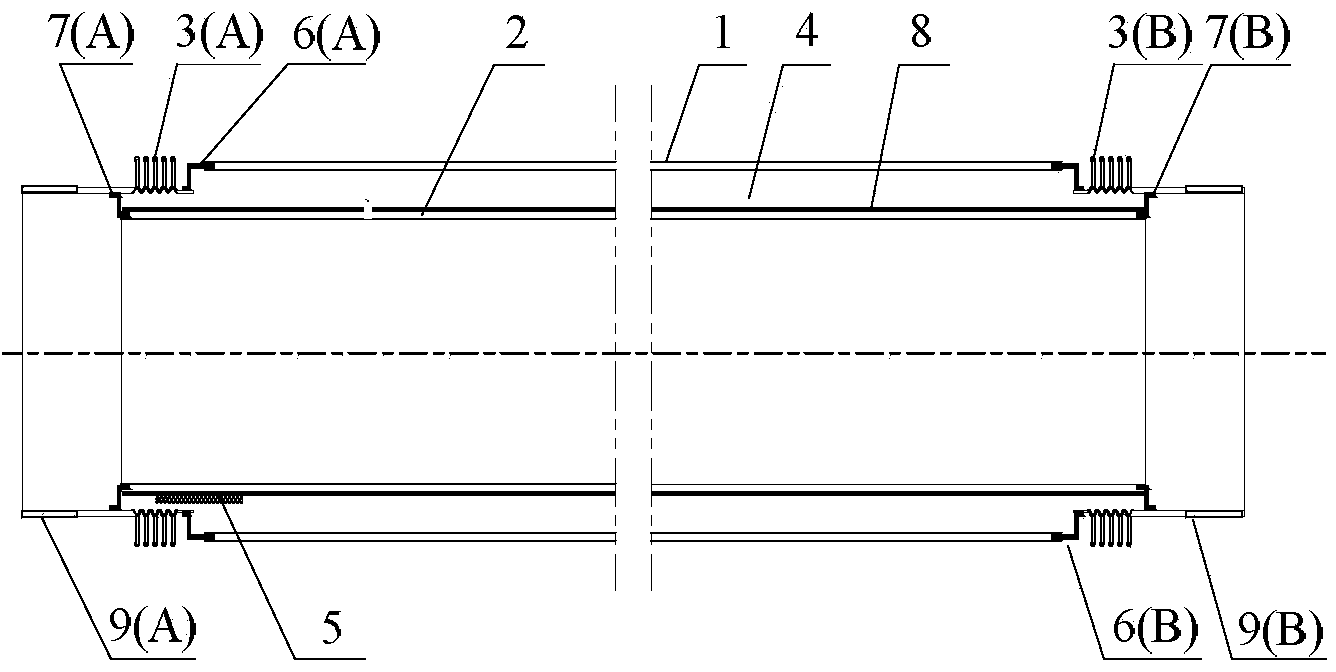

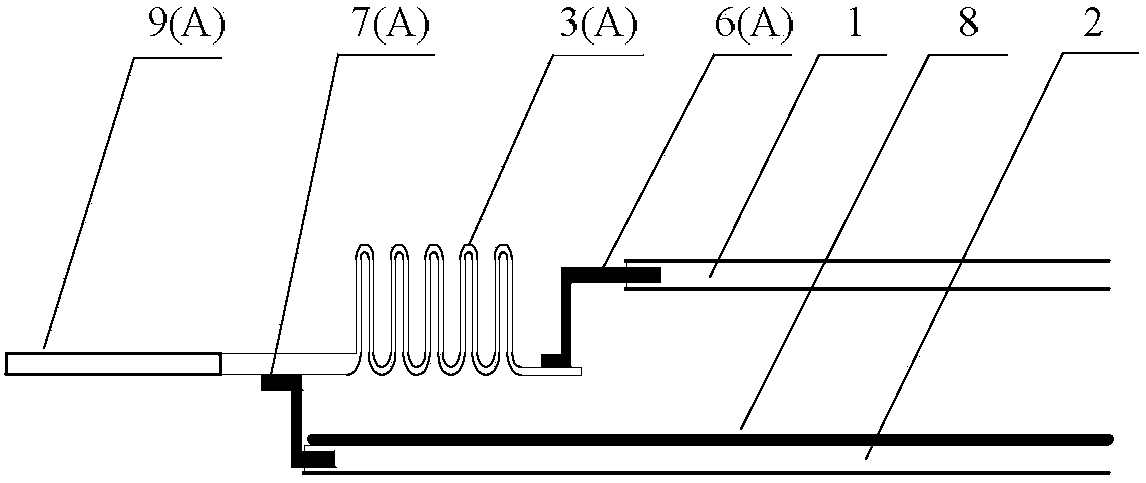

[0028] Such as figure 1 As shown, the present invention discloses a medium-temperature straight-through all-glass vacuum heat collecting tube, which is composed of a glass outer tube 1, a glass inner tube 2, a corrugated expansion joint 3 and a metal connecting tube 9; the glass outer tube 1 and the glass inner tube 2 The space is a vacuum space 4, the outer surface of the glass inner tube 2 is coated with a selective absorption coating 8 with high absorption rate and low emissivity; 1 One end is sealed to one end of the first wave expansion joint 3 (A) through the first transition coupling ring 6 (A), and the other end is sealed to the second wave expansion joint 3 (B) through the second transition coupling ring 6 (B) One end is sealed; the other ends of the first wave expansion joint 3 (A) and the second wave expansion joint 3 (B) respectively pass through the third transition coupling ring 7 (A) and the fourth transition coupling ring 7 (B) and the inner glass Both ends of...

Embodiment 2

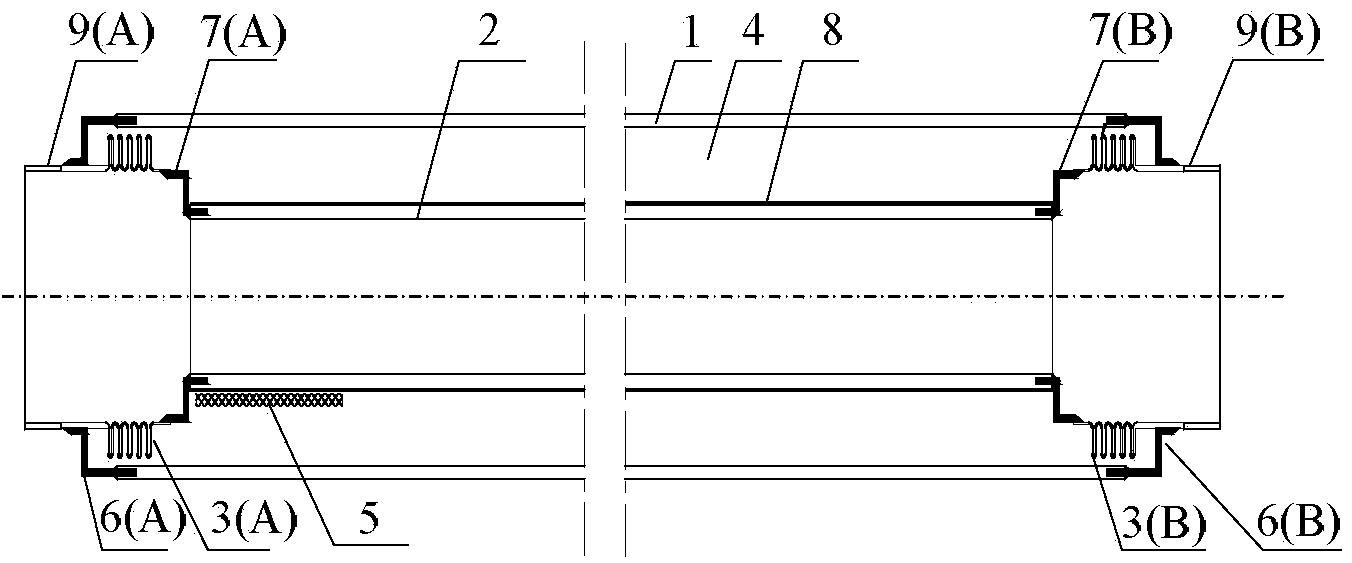

[0031] Such as image 3 Shown is another embodiment of the present invention, the corrugated expansion joint 3 is a built-in type, that is, it is placed inside the glass outer tube 1; the diameter of the glass inner tube 2 is 30mm, and the length is 2m; the diameter of the glass outer tube 1 is The glass inner tube 2 is 10mm larger; the glass outer tube 1 and the glass inner tube 2 are made of borosilicate glass 5.0; the corrugated expansion joint 3 is made of stainless steel, the waveform is U-shaped, and the wave number is 1; the transition connection ring I6 and the transition connection ring II7 The material has an expansion coefficient of 4×10 -6m / (m·℃) Fe-Ni-Co Kovar alloy, sealed with glass outer tube 1, glass inner tube 2 and corrugated expansion joint 3 respectively by fusion sealing connection and solder welding process; the vacuum of vacuum space 4 The degree is 0.01Pa; the absorptivity of the selective absorbing coating is 96%, and the emissivity is 14%. All the ...

Embodiment 3

[0034] In yet another embodiment of the present invention, the corrugated expansion joint 3 is Ω-shaped, and the length of the glass outer tube is 4m; the material of the transition coupling ring I6 and the transition coupling ring II7 is an expansion coefficient of 12×10 -6 m / (m·℃) of stainless steel; sealing with glass outer tube 1, glass inner tube 2 and corrugated expansion joint 3 by fusion sealing connection and solder welding process respectively; the vacuum degree of the vacuum space is 5×10 -5 Pa. All the other structural forms and parameters are the same as in Example 1.

[0035] The heat collecting tube in this embodiment is used in the compound parabolic concentrating system, the heat collecting efficiency of the heat collecting tube reaches 65% to 75%, and the heat collecting temperature range is 0 to 150°C; when the working temperature is 150°C, the thermal stress of the heat collecting tube is higher than that of the straight-through metal- The glass vacuum hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com