Scanning UV-LED exposure device

A technology of UV-LED and exposure device, which is applied in the direction of photolithography exposure device, microlithography exposure equipment, etc., which can solve the problems of irregular scanning speed, need for warm-up preparatory actions, large production space, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

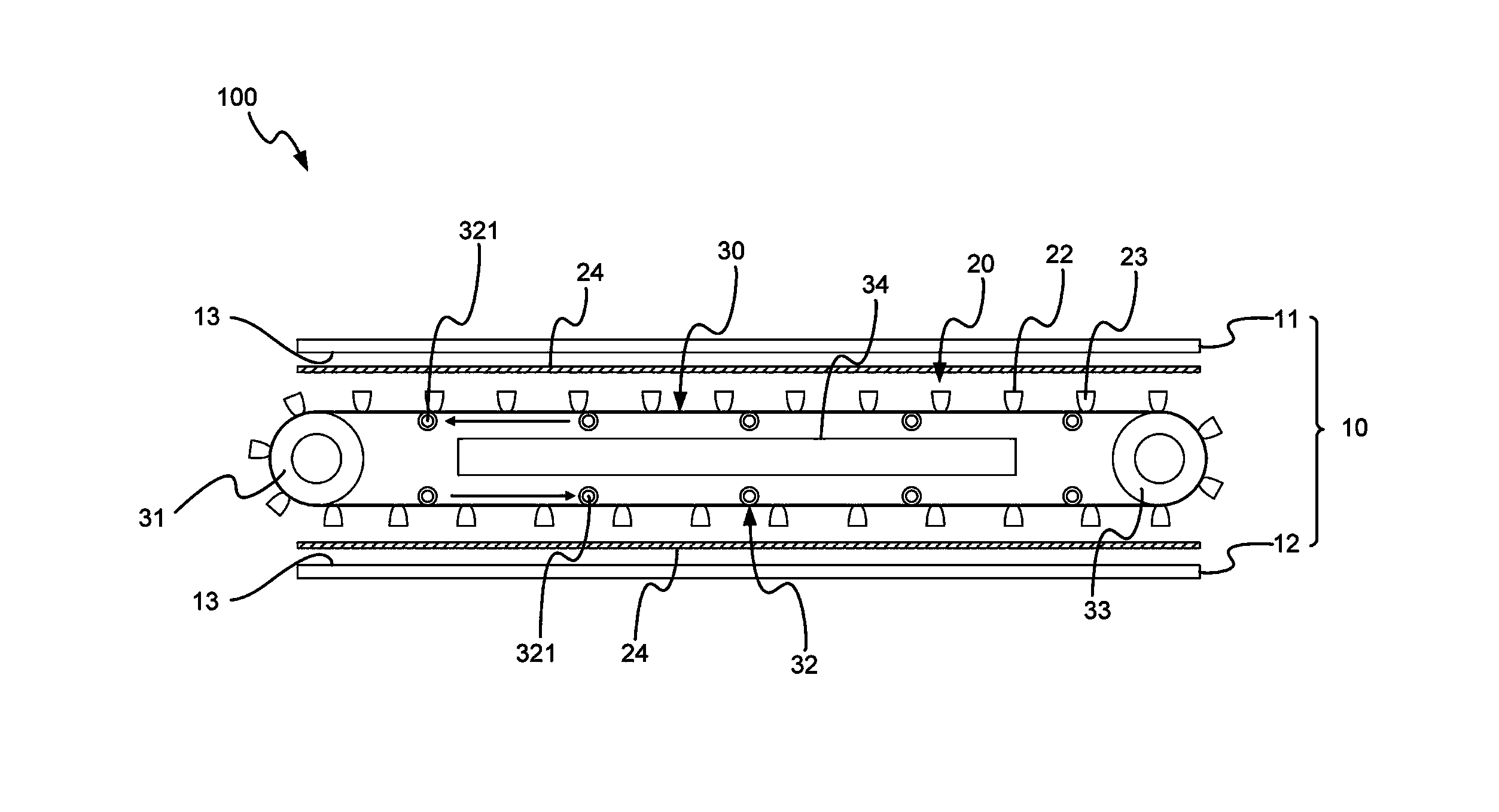

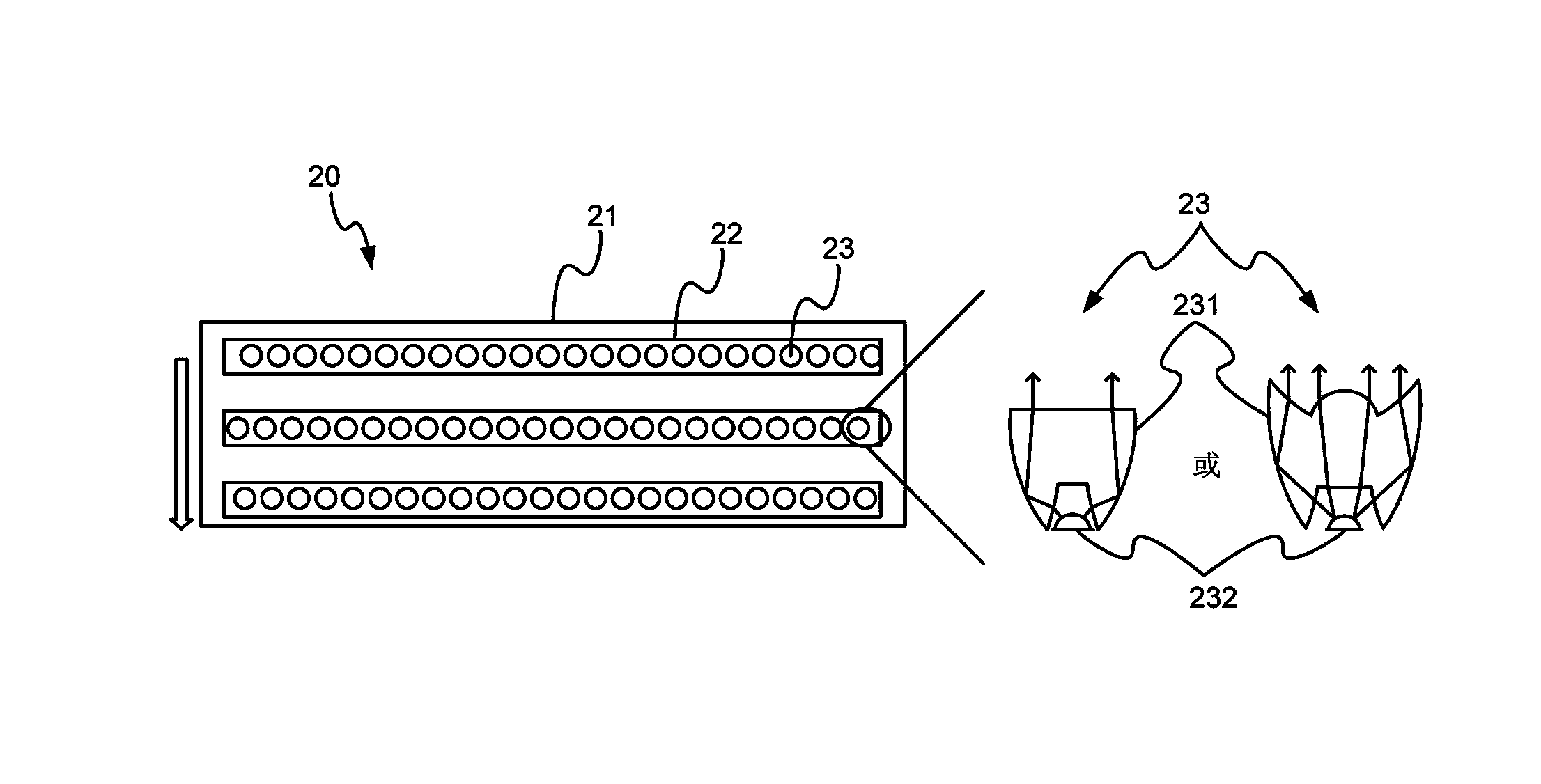

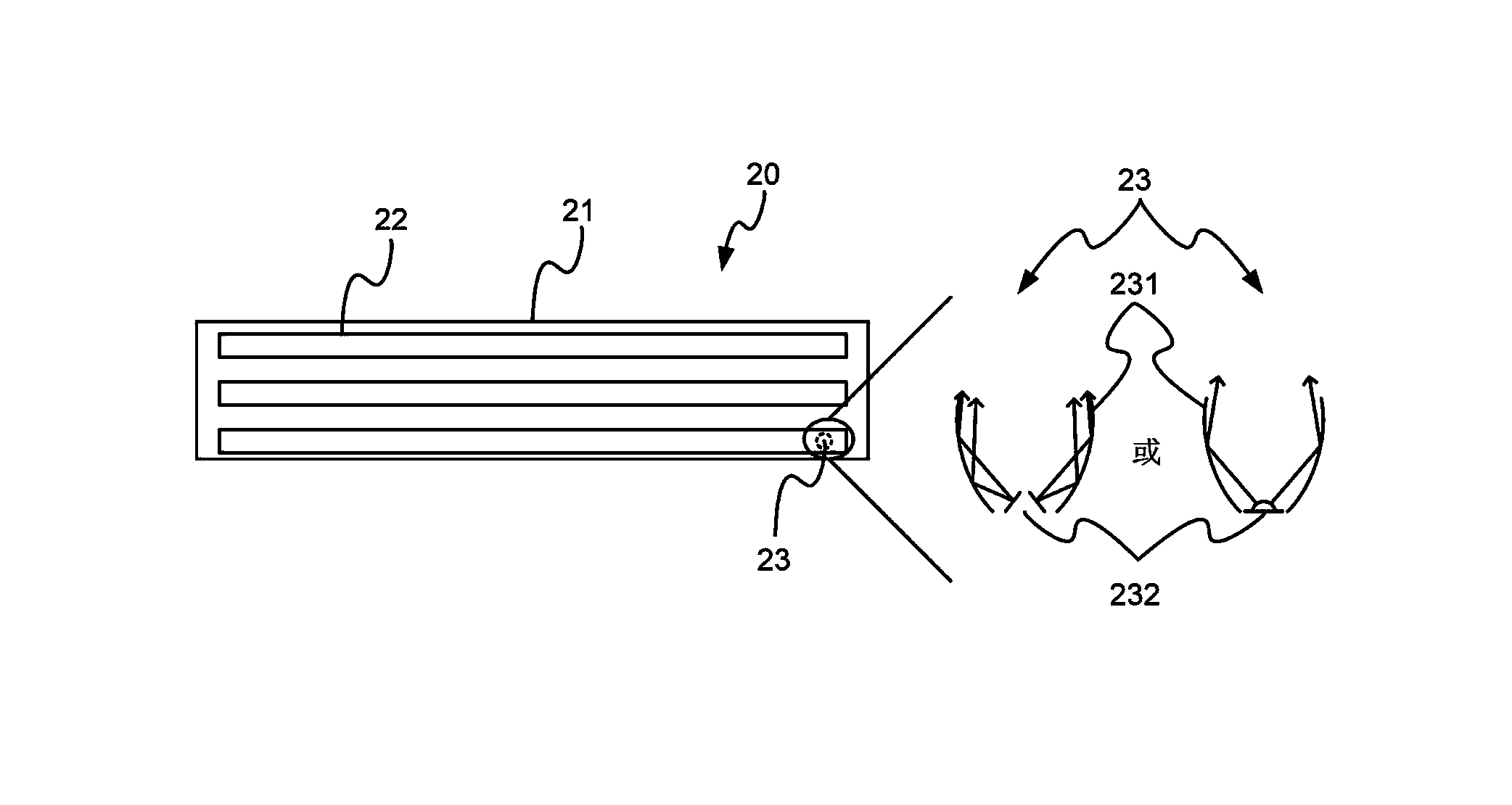

[0035] see Figure 1 to Figure 3 Shown are a schematic structural view of the present invention, a schematic top view of a UV-LED lighting unit according to a specific embodiment of the present invention, and a schematic top view of a UV-LED lighting unit according to another specific embodiment of the present invention. As shown in the figure: the present invention is a scanning UV-LED exposure device, which is an LED exposure machine with the function of large-area divided area exposure. The target exposure area for projection irradiation. The scanning UV-LED exposure device 100 at least includes an exposure unit 10 , a UV-LED lighting unit 20 and a cycle moving ring 30 .

[0036] The above-mentioned exposure unit 10 includes a set of upper exposure stage 11 and lower exposure stage 12 spaced apart from each other, and the corresponding two planes are used to place a substrate (not shown) coated with a photoresist layer. The resist layer is made of photosensitive material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com