Wireless intelligent terminal based remote wireless monitoring method for oxygen stations

A wireless smart terminal, remote wireless technology, applied in the container discharge method, container filling method, electrical components, etc., can solve the problems of high labor cost, high experience and technical level requirements, and large power consumption, etc., to achieve The effect of avoiding personal safety problems, shortening the fault judgment time, and improving the efficiency of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

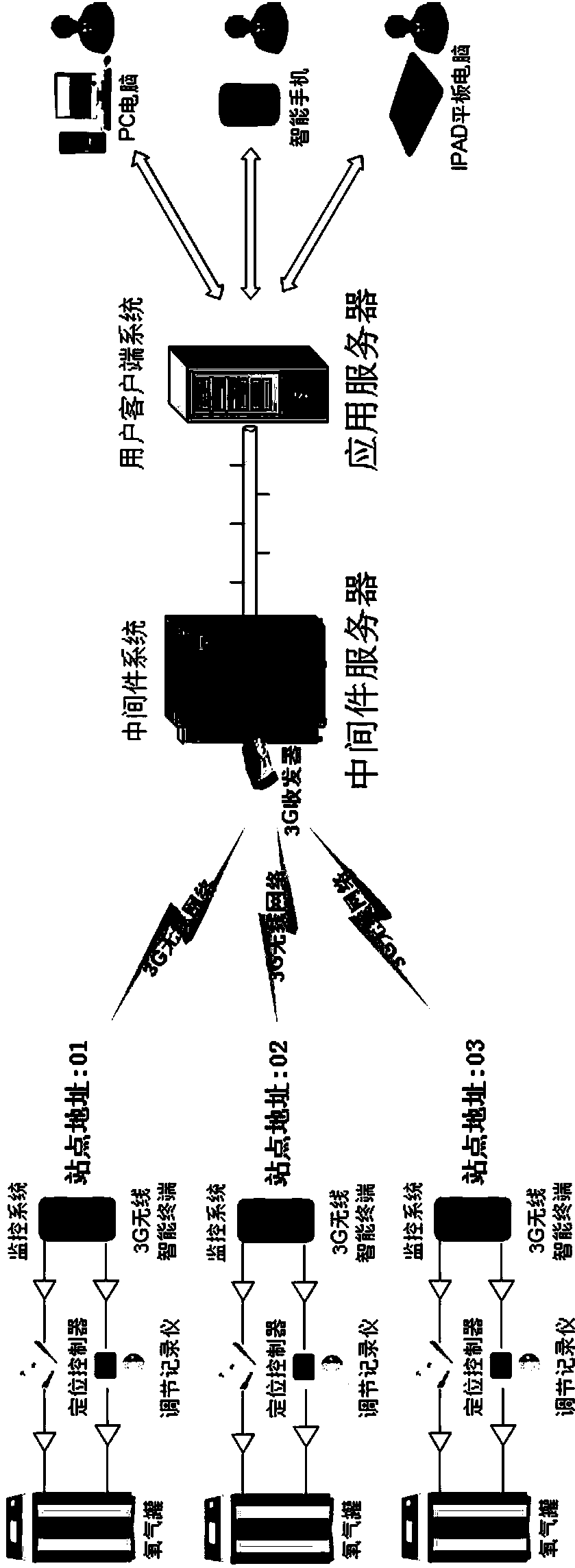

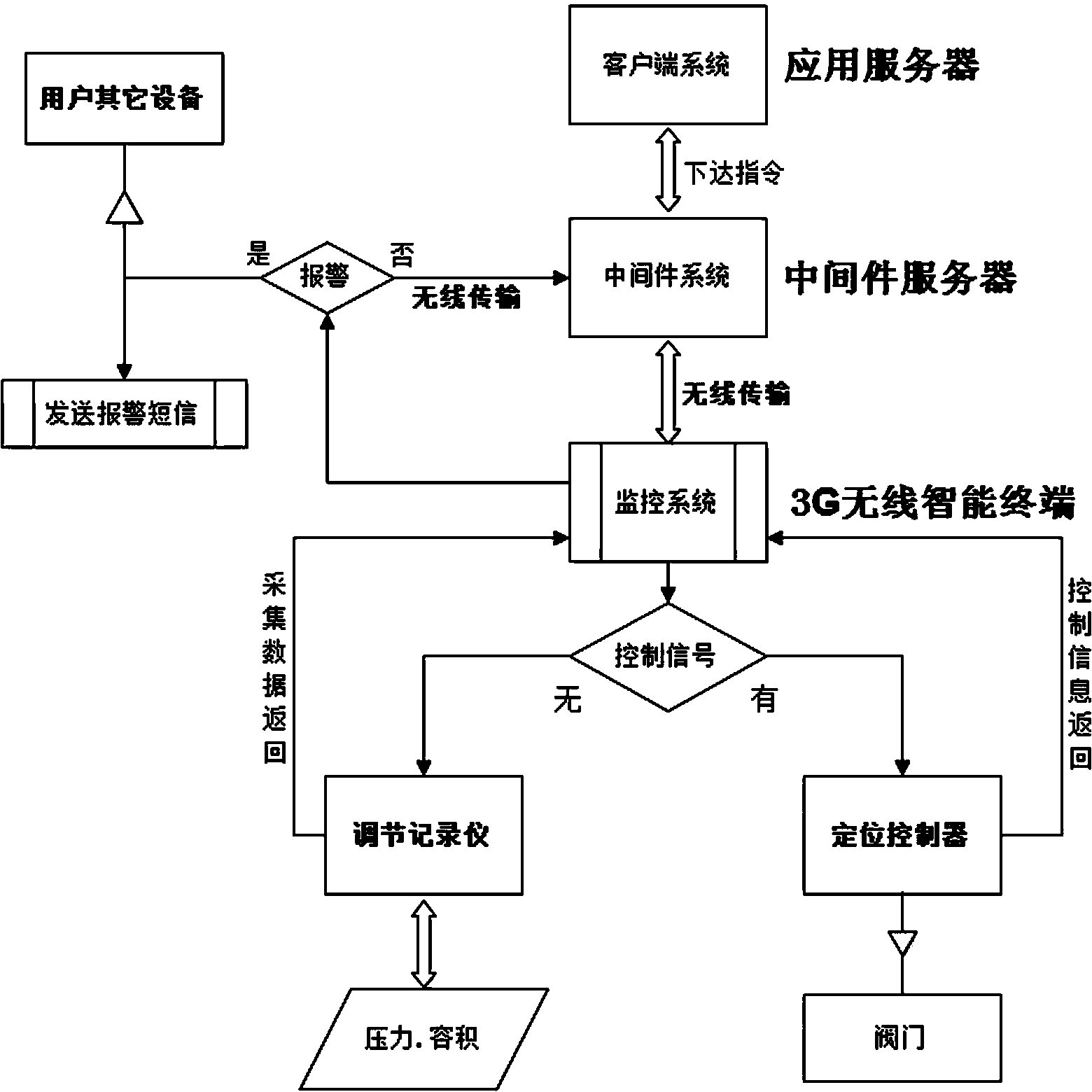

[0031] see figure 1 and figure 2 , a remote wireless monitoring method for an oxygen station based on a wireless smart terminal, which is realized by using a remote wireless monitoring system for an oxygen station based on a smart terminal. , a number of adjustment recorders distributed in each oxygen station for collecting oxygen tank volume and pressure data, and a number of positioning controllers distributed in each oxygen station for controlling the valve of the oxygen tank. The middleware server is connected with a 3G transceiver with a USB interface. The middleware server in this embodiment includes a HP server, a 3G transceiver with a USB interface, a middleware system and a database system running on the server. The application server in this embodiment includes a HP server, and a client system running on the server. The client system is for the client (user) to log in remotely to monitor and control the field equipment in real time. Wherein: the client and the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com