Three-dimensional printer, printing method of three-dimensional printer and printing device of printing method

A three-dimensional printer and print head technology, used in typewriters, printing and other directions, can solve the problems of low color reproduction, low image resolution, and high cost, and achieve the effect of simplifying the structure of the print head, simple imaging process, and low imaging cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

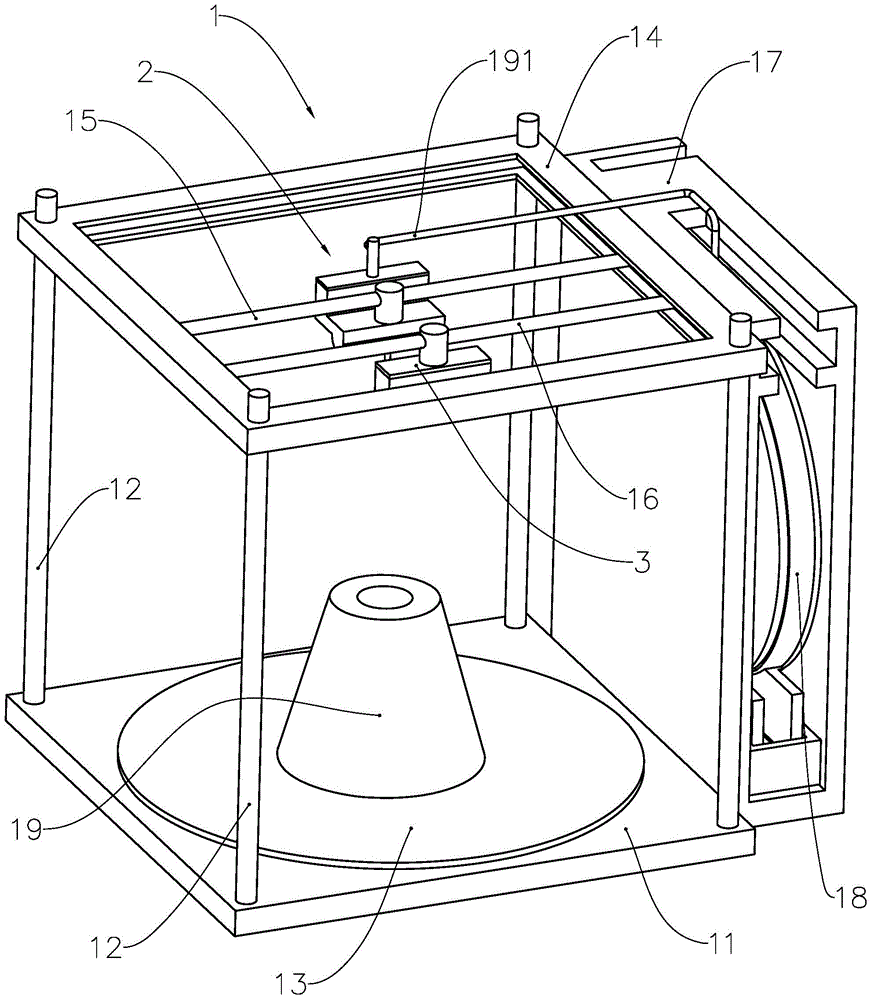

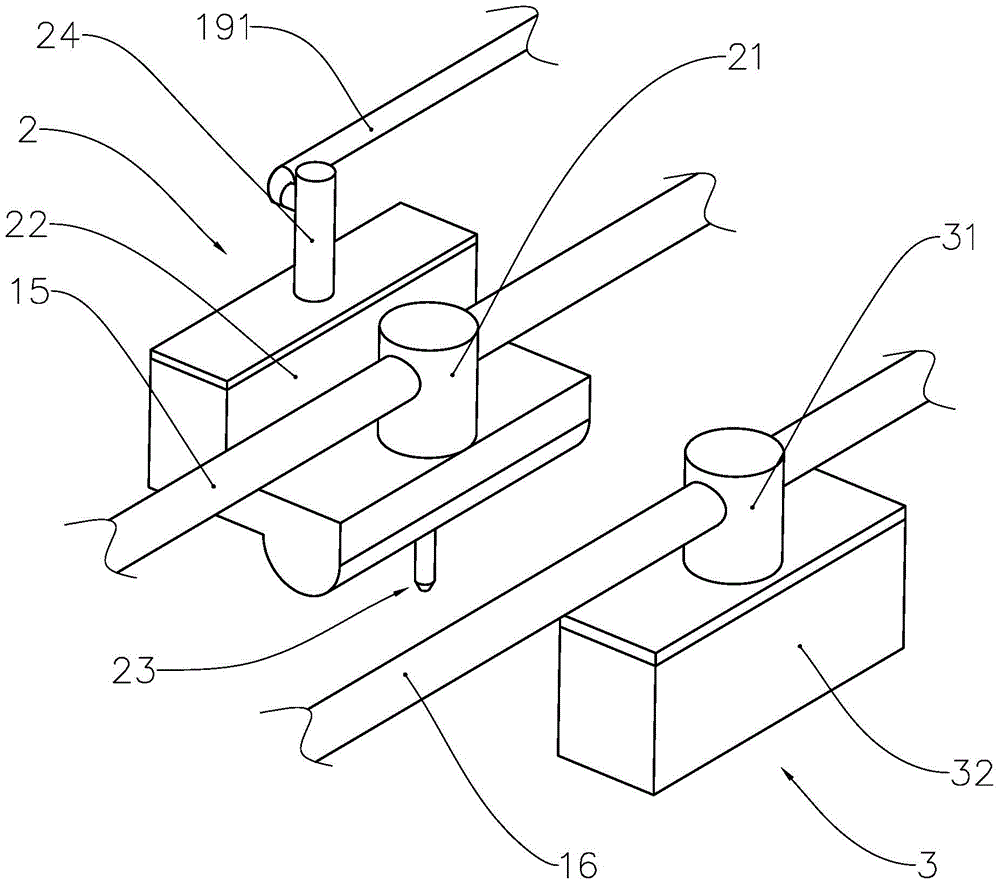

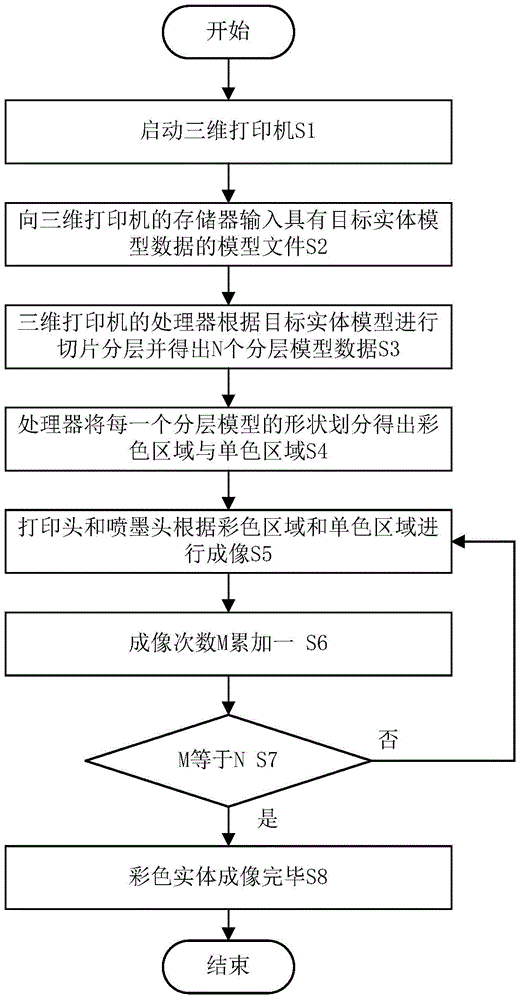

[0045] refer to image 3 , image 3 It is a flow chart of the printing method of the three-dimensional printer. When performing color solid imaging on the 3D solid model 19 , step S1 is first performed to start the 3D printer 1 . Then execute step S2, input the model file with three-dimensional solid model 19 data to the memory of three-dimensional printer 1, then execute step S3, the processor of three-dimensional printer according to such as Figure 4 The three-dimensional solid model 19 shown is sliced and layered, the three-dimensional solid model 19 is a cone, and a through hole is opened along the axis Z of the three-dimensional solid model 19, and the three-dimensional solid model 19 is sliced and divided along the axis Z through the processor. After layering, process the data of N layered models with different diameters, where a layered model such as Figure 5 The hierarchical model 192 is shown. Then step S4 is executed, and the processor divides each layered ...

no. 2 example

[0051] On the basis of the first embodiment of the printing method of the above-mentioned three-dimensional printer, the imaging step S5 of the printing head 2 and the inkjet head 3 can also adopt such as Figure 7 In the sequence of steps, specifically, when step S5 is executed, step S54 is first executed, and the print head 2 ejects the silk material in a molten state according to the color area 193 and the color area 195 for solid imaging, and then step S55 is executed, inkjet The head 3 ejects ink on the layered model 192 according to the color area 193 and the color area 195. After the print head 2 and the inkjet head 3 complete the imaging of the color area, step S56 is performed. 194 ejecting the silk material in the molten state for solid imaging. Of course, the inkjet head 3 can also work simultaneously with the printhead 2, that is, the inkjet head 3 follows the movement track of the printhead 2, and the inkjet head 3 performs color imaging on the filament material j...

no. 3 example

[0053] On the basis of the first embodiment of the printing method of the above-mentioned three-dimensional printer, the imaging step S5 of the printing head 2 and the inkjet head 3 can also adopt such as Figure 8 In the sequence of steps, specifically, when step S5 is executed, step S57 is first executed, and the print head 2 performs physical imaging of the layered model 192 according to the single-layer layered solid model data, and after the layered model 192 completes imaging, then Execute step S58, the inkjet head 3 ejects ink on the layered model 192 according to the color area 193 and the color area 195, using this method can also realize color three-dimensional solid molding, the print head 2 and the inkjet head 3 of this method are Working in different time periods will not interfere with each other, so this printing method is relatively simple.

[0054] The printing device embodiment of three-dimensional printer:

[0055] refer to Figure 9 , Figure 9 It is a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com