Intelligent detection system and method for distribution profile and position of container

A detection system and container technology, applied in the field of detection systems, can solve problems such as inability to apply automatic loading and unloading, inability to determine spatial distance, poor detection accuracy, etc., achieve safe and intelligent automatic handling and storage, reduce loading and unloading box collision accidents, improve The effect of loading and unloading boxes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

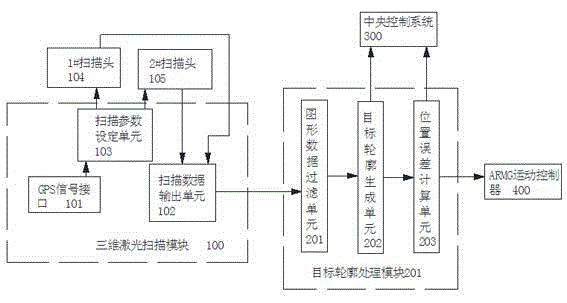

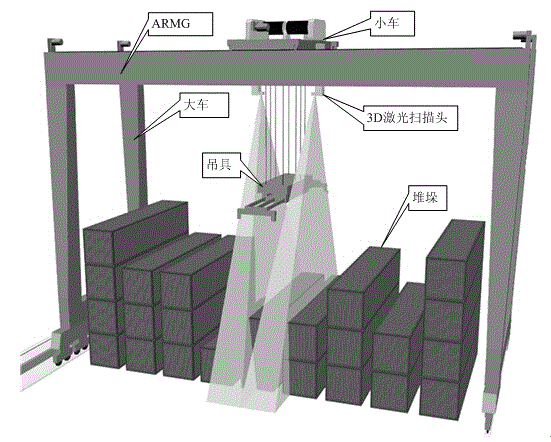

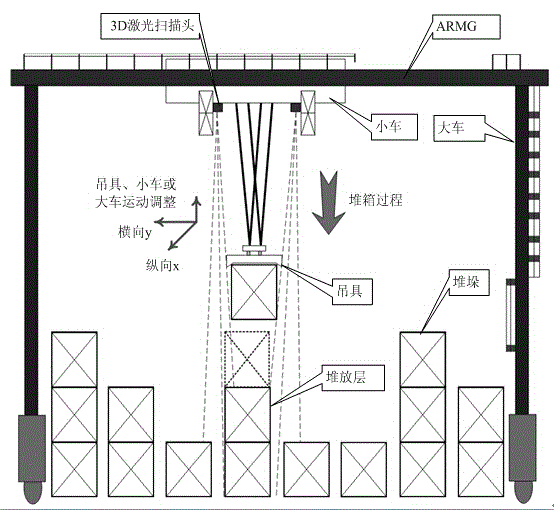

[0036] Such as figure 1 As shown, an intelligent detection system for container distribution contour and position is characterized in that: it includes a central control system 300, a three-dimensional laser scanning module 100, a target contour processing module 200 and an ARMG motion controller 400; the three-dimensional laser scanning The module 100 is connected with the target contour processing module 200; the target contour processing module 200 is connected with the central control system 300 and the ARMG motion controller 400 respectively; wherein, the central control system 300 is used for remote loading and unloading of the container Monitoring and control; the three-dimensional laser scanning module 100 is used to perform rapid and continuous three-dimensional scanning on the stacking of containers, and deliver the scanned information to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com