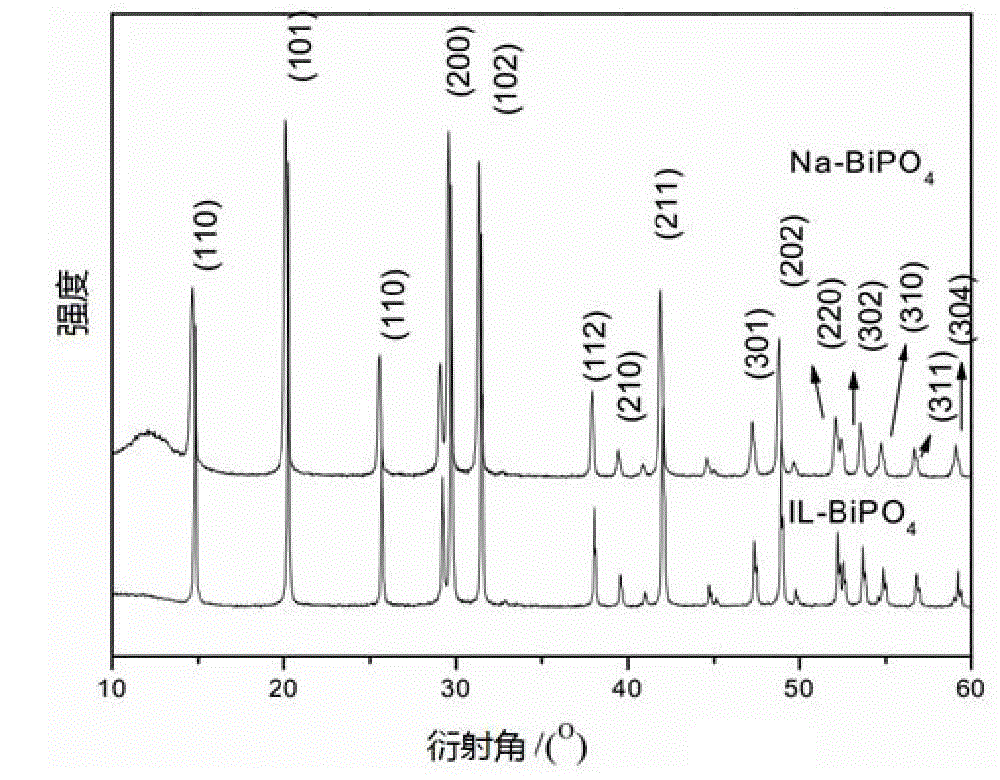

Method for synthesizing spindly bismuth phosphate by adopting imidazole dihydric phosphate type ionic liquid

An imidazole dihydrogen phosphate, ionic liquid technology, applied in phosphorus compounds, chemical instruments and methods, inorganic chemistry and other directions, can solve problems such as poor effect, and achieve the effect of high product purity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

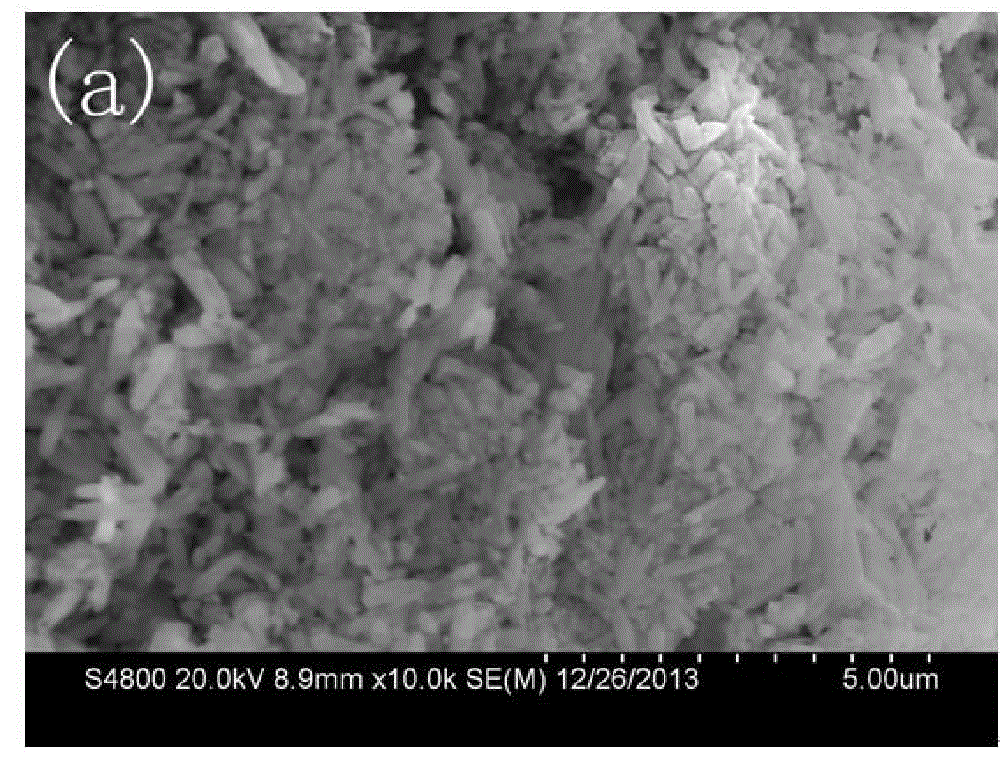

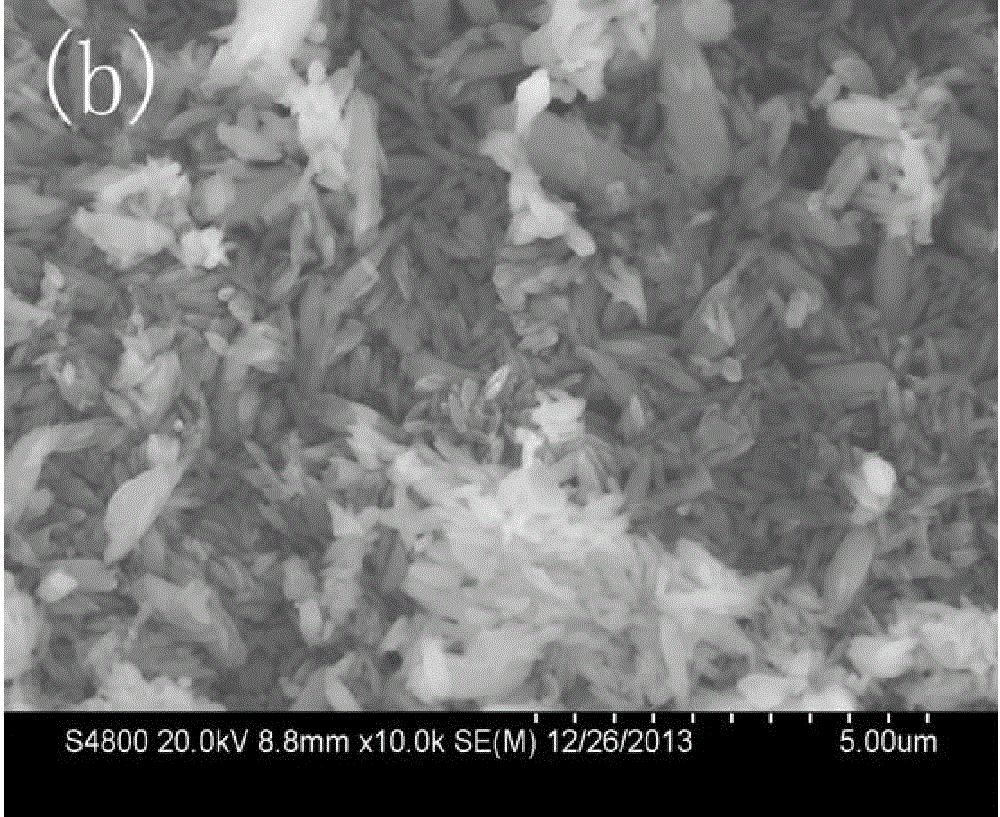

Embodiment 1

[0025] Dissolve 0.5 mol of N-methylimidazole in 100 mL of deionized water, add phosphoric acid dropwise at a molar ratio of 1:1, and stir at 60°C for 2 h. A rotary evaporator is used to remove water and unreacted raw materials in the mixed liquid, and the obtained light yellow viscous liquid is the imidazole dihydrogen phosphate ionic liquid. Dissolve 4.85 g of bismuth nitrate and 1.85 g of imidazolium dihydrogen phosphate ionic liquid in 100 mL of deionized water at an equimolar ratio, sonicate at 60 °C for 2 h, and centrifuge to separate the precipitate. After washing several times and drying in a drying oven at 90 °C for 6 h, the resulting product was spindle-shaped BiPO 4 .

Embodiment 2

[0027] Dissolve 1 mol of N-methylimidazole in 100 mL of deionized water, add phosphoric acid dropwise at a molar ratio of 1:1, and stir at 60°C for 2 h. A rotary evaporator is used to remove water and unreacted raw materials in the mixed liquid, and the obtained light yellow viscous liquid is the imidazole dihydrogen phosphate ionic liquid. Dissolve 4.85 g of bismuth nitrate and 1.85 g of imidazolium dihydrogen phosphate ionic liquid in 100 mL of deionized water at an equimolar ratio, sonicate at 60 °C for 2 h, and centrifuge to separate the precipitate. After washing several times and drying in a drying oven at 90 °C for 6 h, the obtained product was spindle-shaped BiPO 4 .

Embodiment 3

[0029] Dissolve 0.5 mol of N-methylimidazole in 100 mL of deionized water, add phosphoric acid dropwise at a molar ratio of 1:1, and stir at 60°C for 2 h. A rotary evaporator is used to remove water and unreacted raw materials in the mixed liquid, and the obtained light yellow viscous liquid is the imidazole dihydrogen phosphate ionic liquid. Dissolve 9.7 g of bismuth nitrate and 3.7 g of imidazolium dihydrogen phosphate ionic liquid in 100 mL of deionized water at an equimolar ratio, sonicate at 60°C for 2 h, centrifuge to separate the precipitate, and wash with deionized water and absolute ethanol After washing several times and drying in a drying oven at 90 °C for 6 h, the obtained product was spindle-shaped BiPO 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com