Waterborne colorful lacquer composite exterior wall construction paint

A technology of building exterior walls and real stone paint slurry, which is applied in the field of coatings, can solve problems such as unsuitable operation and complicated construction technology, and achieve the effects of reducing labor intensity, excellent aging resistance, and reducing decoration costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

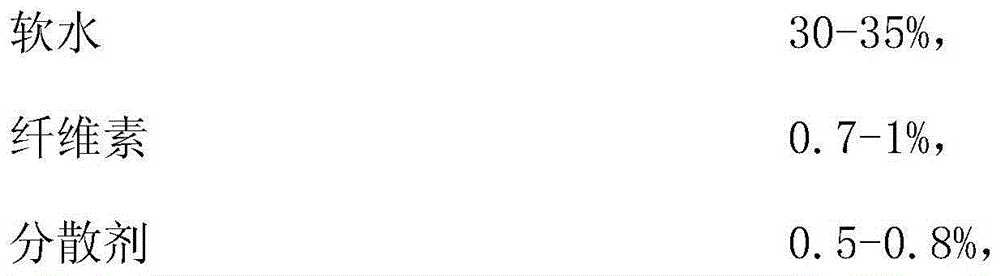

[0045] A water-based real stone varnish multicolor composite building exterior wall coating, the raw material formula is real stone varnish slurry, colorful color dots, and the weight percentage of each color sand is: 20:45:35.

[0046] The preparation steps of the colorful composite building exterior wall paint of the water-based real stone paint are:

[0047] A: Put the real stone paint slurry into the reaction kettle, turn on 100 rpm and put in colorful dots, and disperse for 1 minute to achieve uniform color particles;

[0048] B: Add each color sand in turn, pay attention to the slow addition process, to prevent the multi-color dots and high-concentration color sand from becoming broken due to dry friction, stir evenly after adding, and stir at the same speed for 3 minutes to prepare water-based real stone paint Colorful composite building exterior wall paint;

[0049] The components and weight percentages of the real stone paint slurry are as follows: soft water 35.4, c...

Embodiment 2

[0073] A water-based real stone lacquer multicolor composite building exterior wall coating, the raw material formula is real stone varnish slurry, colorful color dots, and the weight percentage of each color sand is: 30:35:35.

[0074] The preparation steps of water-based real stone paint colorful composite building exterior wall paint are as follows:

[0075] A: Put the real stone paint slurry into the reaction kettle, turn on 100 rpm and put in colorful dots, and disperse for 1 minute to achieve uniform color particles;

[0076] B: Add each color sand in turn, pay attention to the slow addition process, stir evenly after adding, then stir at the same speed for 2 minutes to prepare water-based real stone paint colorful composite building exterior wall paint.

[0077] The components and weight percentages of the real stone paint slurry are as follows: soft water 45, cellulose (HBR250) 0.4, film-forming aid propylene glycol monobutyl ether (BCS) 2, film-forming aid (TEXANOL) 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com