A method for improving the performance of nickel-chromium-iron electric heating alloy

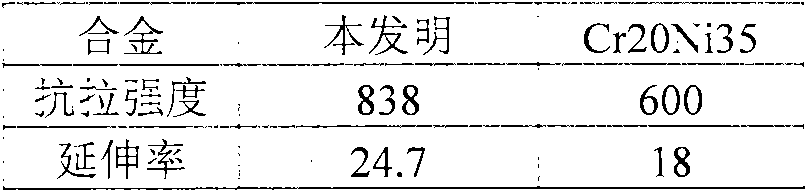

A technology of electrothermal alloy and nickel-chromium iron, which is applied in the field of electrothermal alloy material preparation, can solve problems such as gaps and uneven product quality, and achieve the effects of increasing service life, improving oxidation resistance, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Further illustrate and understand the present invention through embodiment below.

[0020] A method for improving the performance of a nickel-chromium-iron electrothermal alloy, characterized in that the method comprises the following steps: (1) preparing a master alloy ingot by using a non-consumable electromagnetic induction melting process, the elemental composition and quality of the master alloy ingot The ratio is: C: 0.08%, Si: 0.3%, Mn: 0.5%, Al: 2.5%, Cr: 12%, Ni: 44%, Hf: 1.6%, Nb: 2%, V: 1.1%, Mo : 1.7%, B: 0.09%, S ≤ 0.001%, P ≤ 0.001%, the balance is iron and unavoidable impurities; (2) The master alloy is prepared by powder metallurgy process, including: 1-3 micron high-purity nickel powder and 0.1-0.2 micron yttrium oxide powder are mixed evenly by mechanical ball milling, the mass ratio of the two is 100:5, and the ball milling time is 55 hours. After mixing evenly, put the above powder into the discharge plasma sintering equipment, and add Edge pressing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com