Air-coupled transducer based on air-based 1-3 type piezoelectric composite material

A piezoelectric composite material and sensor technology, which is applied in the analysis of materials, material analysis using sonic/ultrasonic/infrasonic waves, and instruments, etc., can solve the problems of high impedance difference of sensors, high impedance difference between detection medium and air, and high ultrasonic attenuation. Achieve the effect of increasing ultrasonic energy, reducing acoustic impedance and reducing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

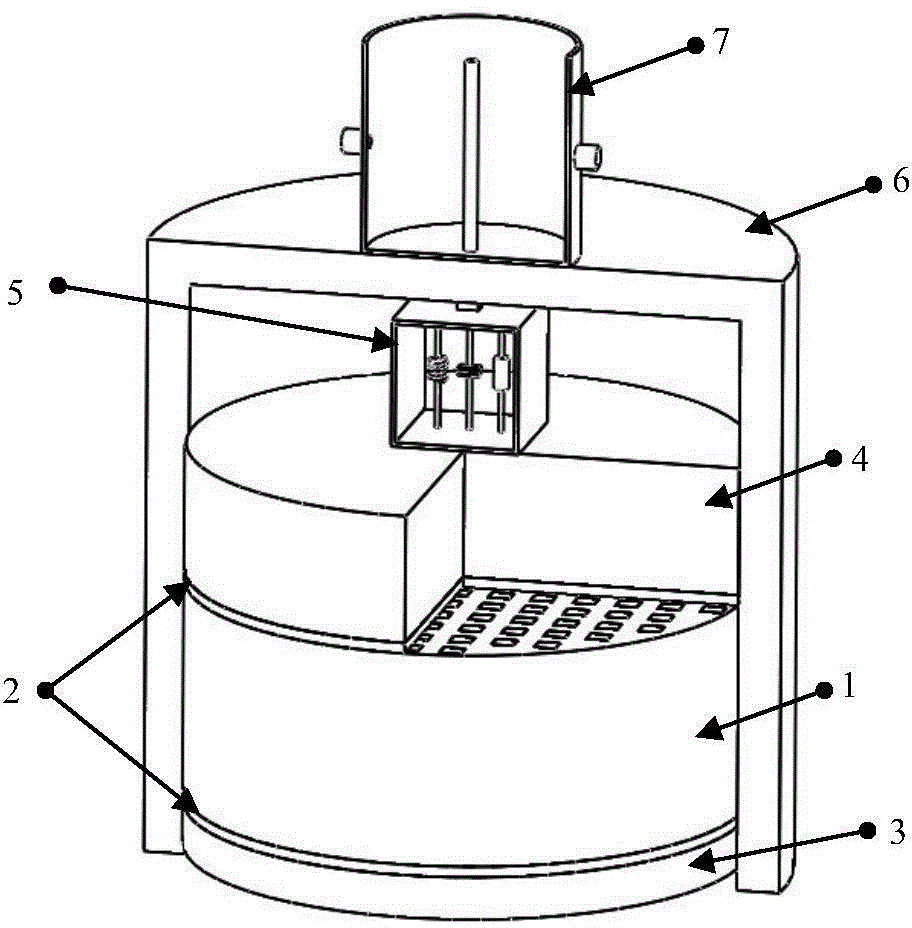

[0036] Such as Figure 1-7b As shown, an air-coupled sensor based on a gas-based 1-3 type piezoelectric composite material, the sensor includes a 1-3 type piezoelectric composite material wafer 1, an electrode 2, a transmission layer 3, a damping layer 4, and an impedance matching circuit 5 , sensor shell 6, BNC interface 7; Wherein, electrode is plated on the surface of 1-3 type piezoelectric composite wafer 1, and is bonded together with matching layer and damping layer 4 concentrically, and the lead wire that upper and lower electrode 2 draws out through impedance The matching circuit 5 is connected to the BNC interface 7 .

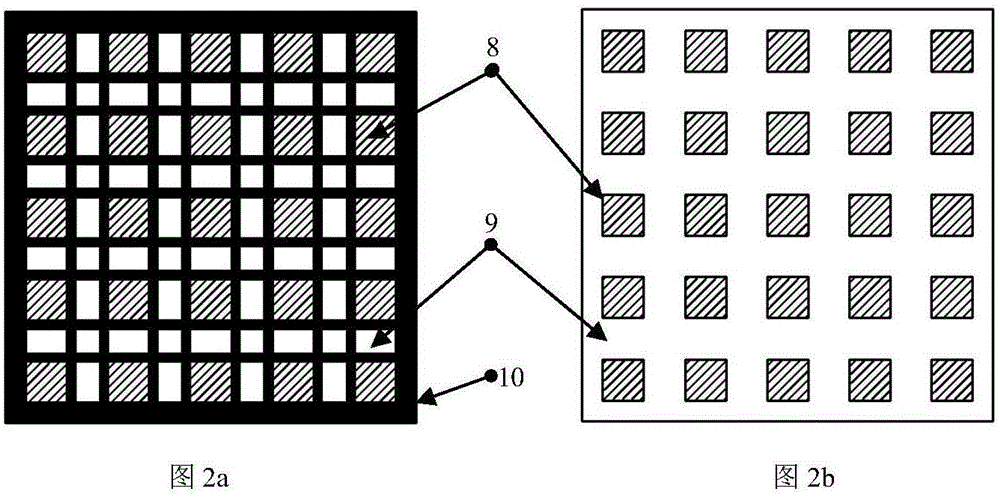

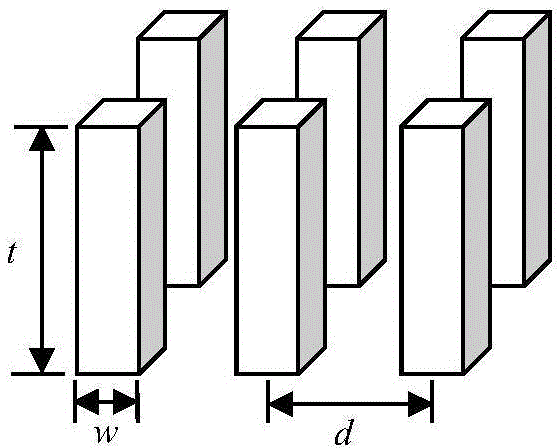

[0037] The 1-3 type piezoelectric composite material wafer 1 is produced by using air instead of traditional polymers and composited with piezoelectric pillars. The piezoelectric pillars are cut from the whole piece of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com