Establishment method of simulation model for fdtd ultrasonic testing of coarse-grained materials based on ebsd map

A simulation model and method establishment technology, which is applied in the analysis of materials, material analysis using sound waves/ultrasonic waves/infrasonic waves, and measurement devices, and can solve problems that affect model calculation accuracy, grain structure, and orientation distortion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The establishment method of FDTD ultrasonic testing simulation model for coarse-grained materials based on EBSD maps, taking the Z3CN20-09M main pipeline material of a pressurized water reactor nuclear power plant with a thickness of 96mm as an example, includes the following steps:

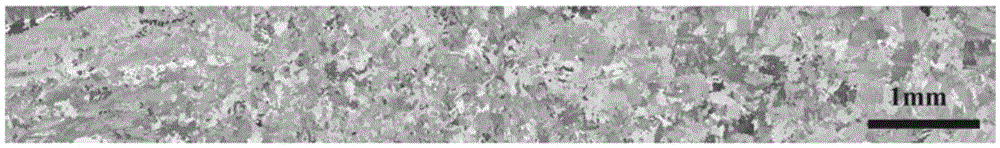

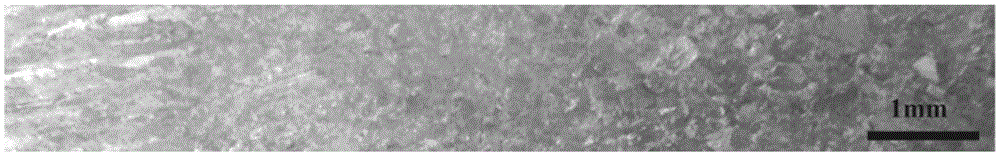

[0033] (1) Taking Z3CN20-09M with a thickness of 96mm as the research object, cut a sample of 96mm×12mm×2mm along the pipeline axis-radial direction, and then cut the sample into four pieces of 24mm×12mm×2mm for EBSD analysis, and the rest with Time-domain waveforms for ultrasonic testing. According to the national standard "GB / T19501-2004 General Principles of Electron Backscatter Diffraction Analysis Method", the samples were pretreated by grinding, mechanical polishing, and stress-relieving electrolytic polishing. Select 40μm scan step to perform EBSD analysis on the sample to be tested;

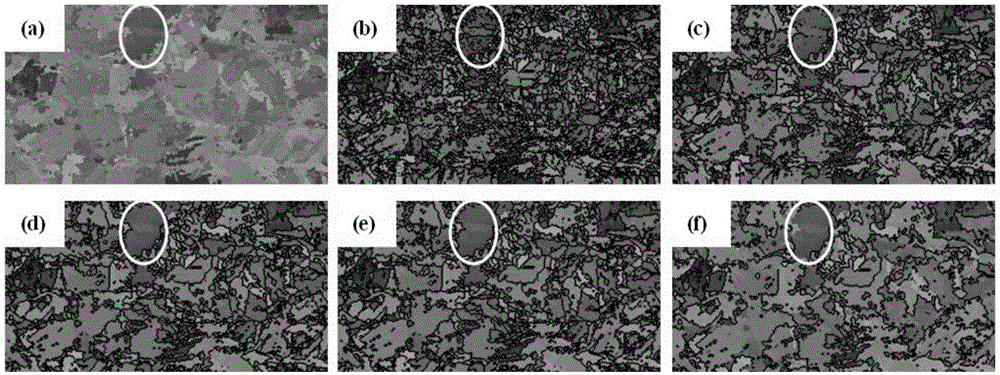

[0034] (2) As a microscopic measurement tool, EBSD can only scan 6mm at a time 2 Areas need to b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com