Bi-directional phase-shifted full-bridge soft switch circuit

A phase-shifting full-bridge and soft-switching technology, applied in electrical components, adjusting electrical variables, high-efficiency power electronics conversion, etc., can solve the problems of large switching loss, energy waste, hard-switching power supply frequency can not be too high, etc., to achieve low power circulation and current stress, reducing volume and quantity, and improving energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

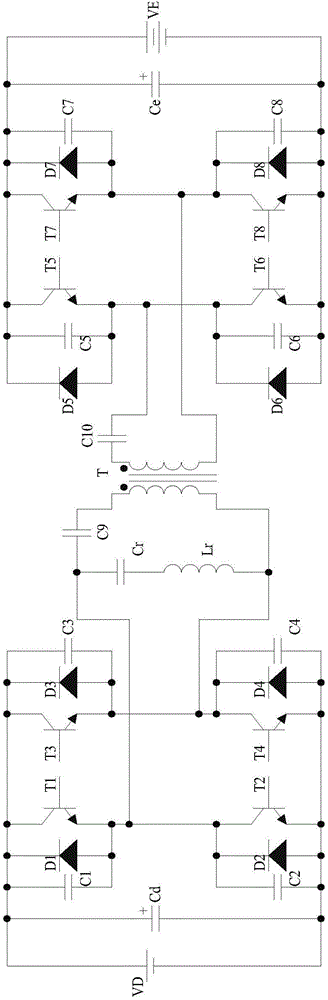

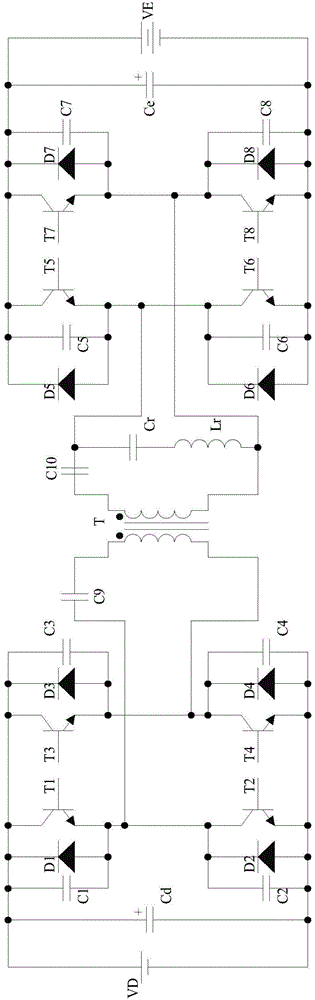

[0016] see figure 1 and figure 2 As shown, the bidirectional phase-shifting full-bridge soft switch circuit of the present invention includes a transformer T, a first bidirectional phase-shifting full-bridge circuit, a second bidirectional phase-shifting full-bridge circuit and a resonant circuit, and the transformer T is respectively connected to the The first bidirectional phase-shifting full-bridge circuit and the second bidirectional phase-shifting full-bridge circuit.

[0017] The resonant circuit in the present invention includes a DC blocking capacitor C9, a DC blocking capacitor C10, a resonant inductance Lr and a resonant capacitor Cr, and the resonant inductance Lr is connected in series with the resonant capacitor Cr;

[0018] The first bidirectional phase-shifting full-bridge circuit includes a switching tube T1, a switching tube T2, a switching tube T3 and a switching tube T4, the switching tube T1 and the switching tube T2 are connected in series to form a firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com