Special intelligent lopper saw for high-voltage live working robots

A working robot and special intelligent technology, applied in the direction of agricultural machinery and implements, instruments, applications, etc., to achieve the effect of reducing structural space, reducing weight, and eliminating the impact of dynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

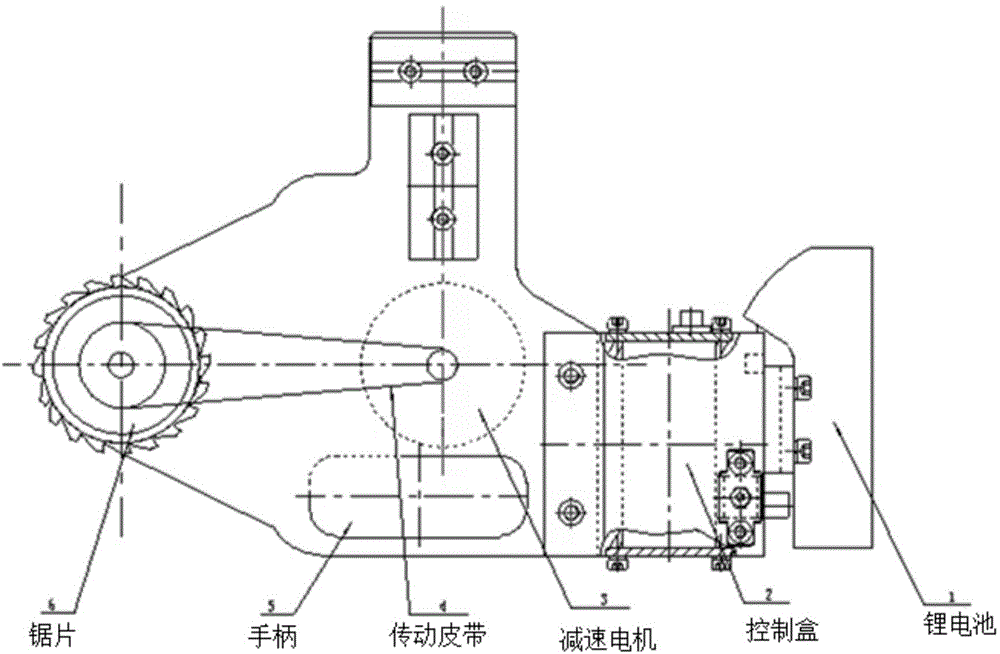

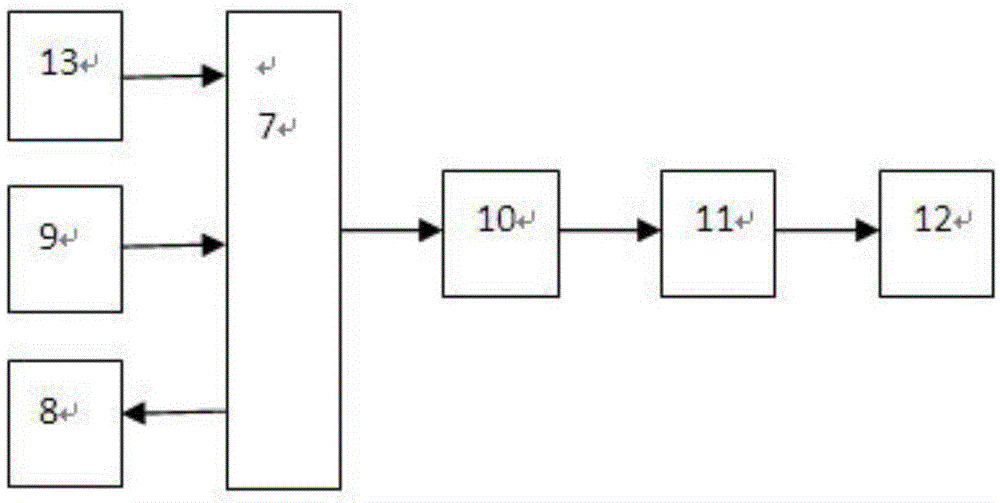

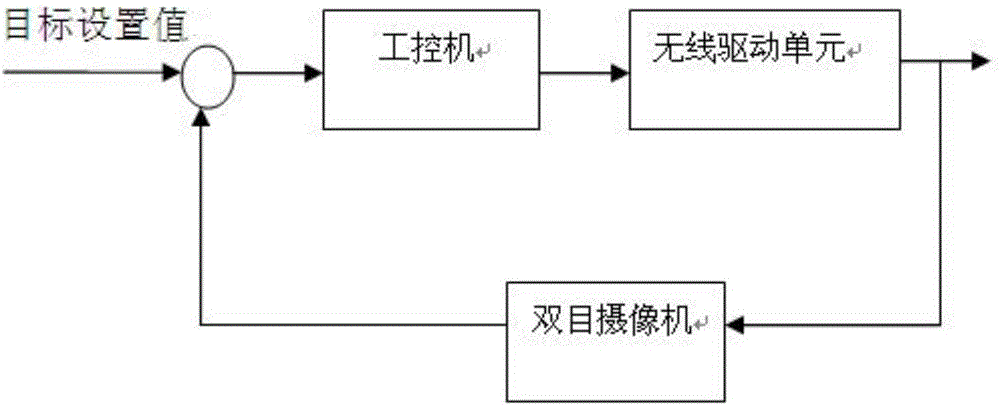

[0039] like figure 1 As shown, the present invention consists of a high-branch saw body, an intelligent transmitter remote control, and a receiver and motor driver;

[0040] The main body of the high-branch saw includes a lithium battery 1 to provide 24V, 3A DC power for the high-branch saw. The battery is light in weight and has a large capacity. It is the current standard power supply for electric tools and is interchangeable.

[0041] The control box 2 integrates the rack interface, battery interface, and controller installation functions into one. On the one hand, the control box is connected to the frame through the positioning notch, the mechanical structure is compact and reliable, the controller is completely installed in the control box, and the metal control box acts as a shield to ensure the safe and reliable operation of the controller in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com