Fish meal drier

A dryer and fishmeal technology, applied in the field of dryers and fishmeal dryers, can solve problems such as scaling easily, and achieve the effects of reducing energy consumption, fast drying, and good self-locking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

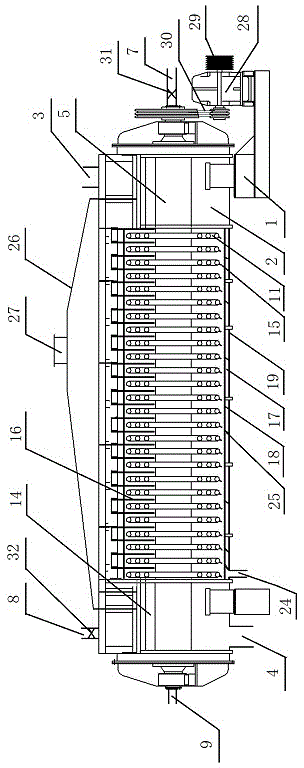

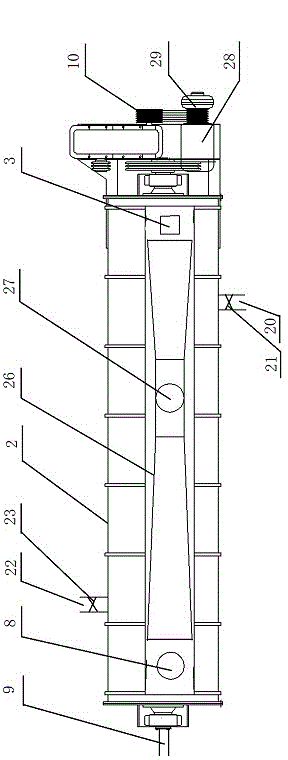

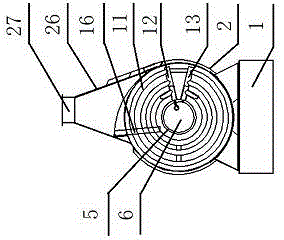

[0021] The present invention will be further described below in conjunction with the drawings.

[0022] Such as figure 1 , figure 2 The fishmeal dryer shown includes a base 1 and a tank 2 installed on the base 1. The base 1 is set as a steel structure base 1, so there is no need to provide a concrete foundation, and the installation position can be changed at will; A raw material inlet 3 is provided above one end of the tank body 2, and the raw material inlet 3 is connected to the outlet of the squeezing device. A raw material outlet 4 is provided below the other end of the tank body 2, and the raw material outlet 4 is connected to the cooling device In this way, the entire fishmeal production line is connected together to meet the needs of continuous automated production. A hollow shaft 5 is arranged in the tank body 2. The hollow shaft 5 is provided with a hollow inner cavity 6, and the hollow shaft 5 is connected with a steam pipe. The steam in the steam pipe can enter the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com