High-adsorbability powdered material forming technology based on 3D printing technology

A powder material, 3D printing technology, applied in other chemical processes, chemical instruments and methods, etc., can solve the problems of long processing cycle, damage to the natural excellent properties of tourmaline materials and diatomite materials, and product quality discounts, etc. The effect of adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0026] A forming process for highly absorbent powder materials based on 3D printing technology, comprising the following steps:

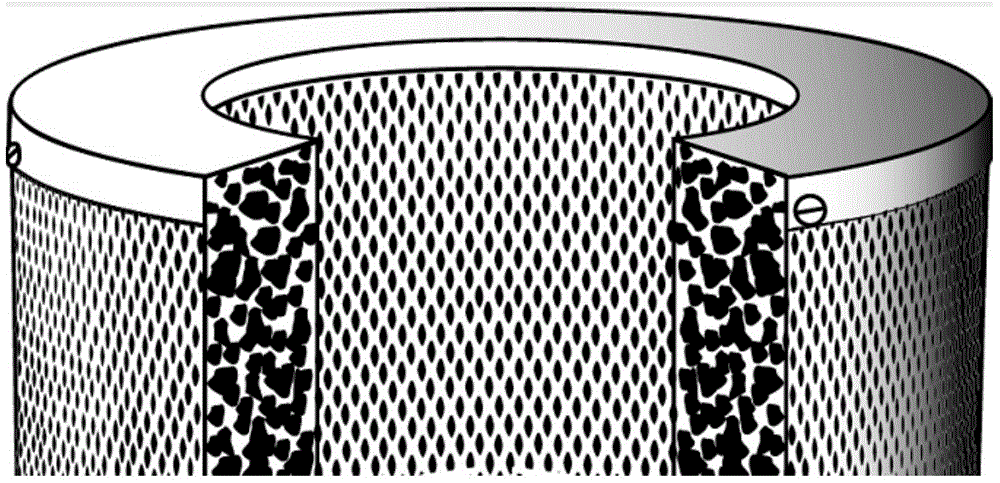

[0027] 1) Refer to figure 1 , mix the main material and auxiliary materials together, calculated by mass fraction, the proportion of the main material is 10% to 90%, the main material is tourmaline or diatomite powder material, and the auxiliary materials are quartz, zeolite powder, zirconia, oxide The mesh of titanium, nickel powder or borax powder, tourmaline powder or diatomite powder is 10 mesh to 200 mesh, such mixed powder can form parts with high adsorption performance;

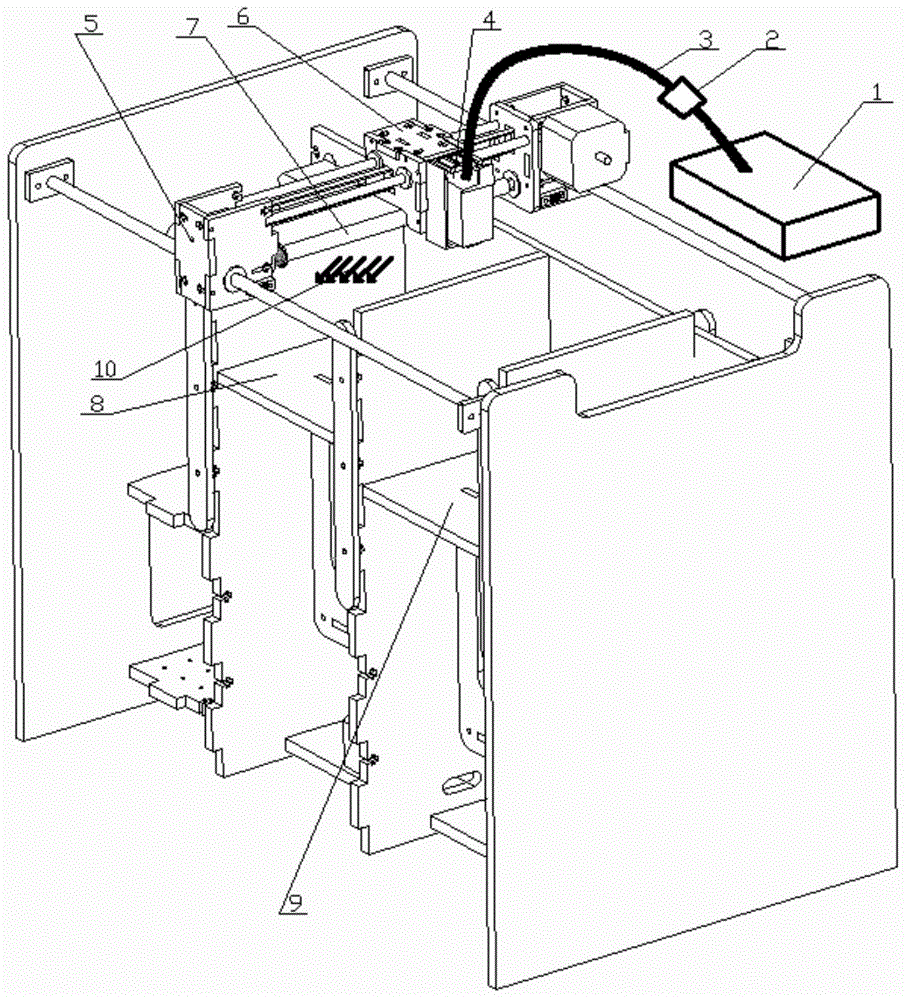

[0028] 2) Refer to figure 2 , put the mixed powder material into the powder supply cylinder 9 of the 3D printing equipment, and then store the binder in the external supply binder box 1, and the binder is always replenished by the conduit 3 under the dri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com