A double-turret double-channel CNC vertical lathe

A CNC vertical, dual-channel technology, applied in the field of CNC lathes, can solve the problems of poor stability, low production precision, and bulky lathes, and achieve the effects of compact structure, improved production efficiency, and reduced motion paths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0088] In order to further explain the technical solution of the present invention, it will be described in detail below in conjunction with the accompanying drawings.

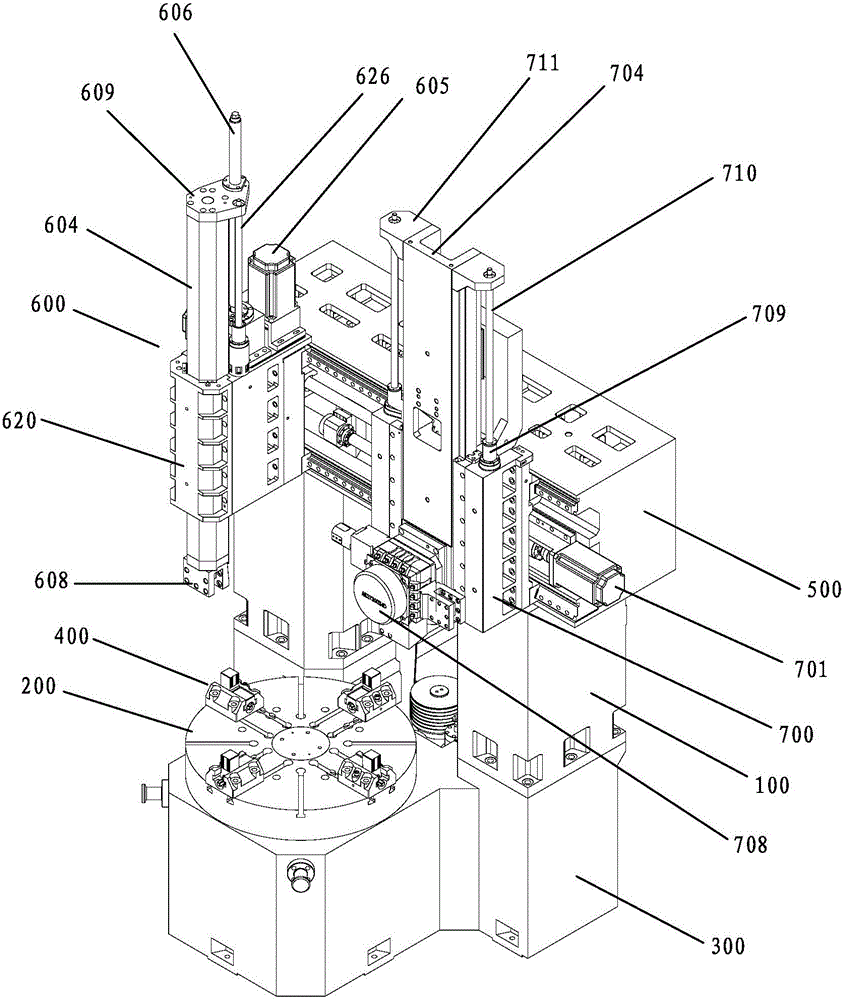

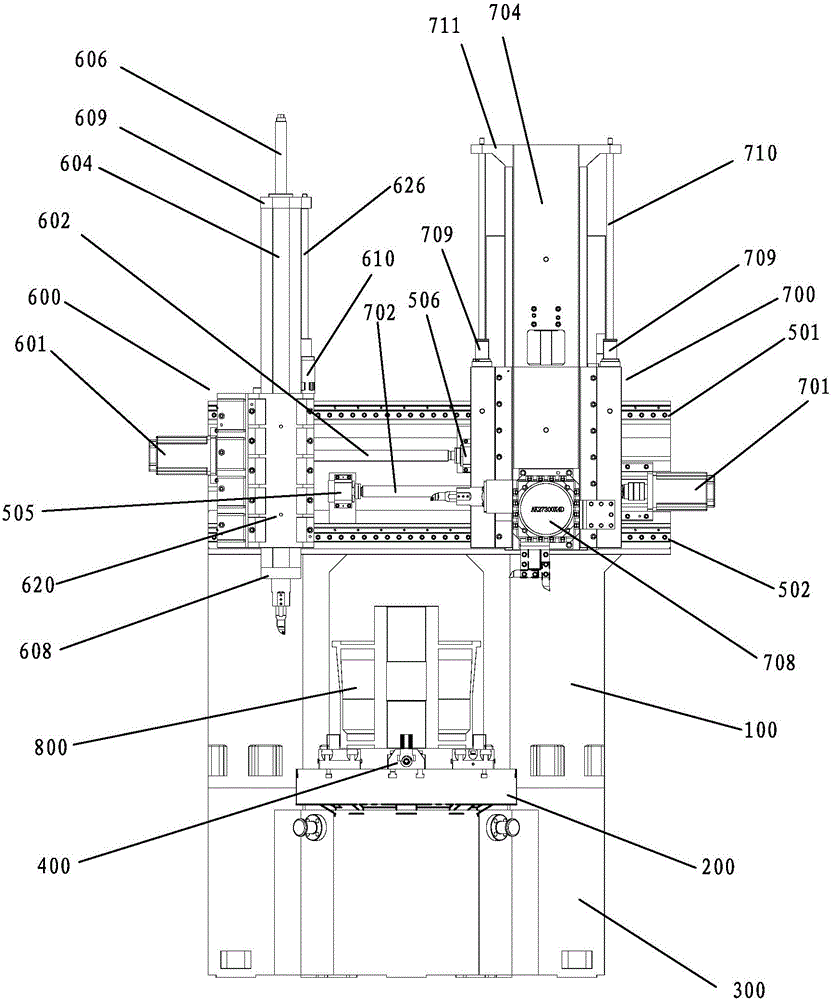

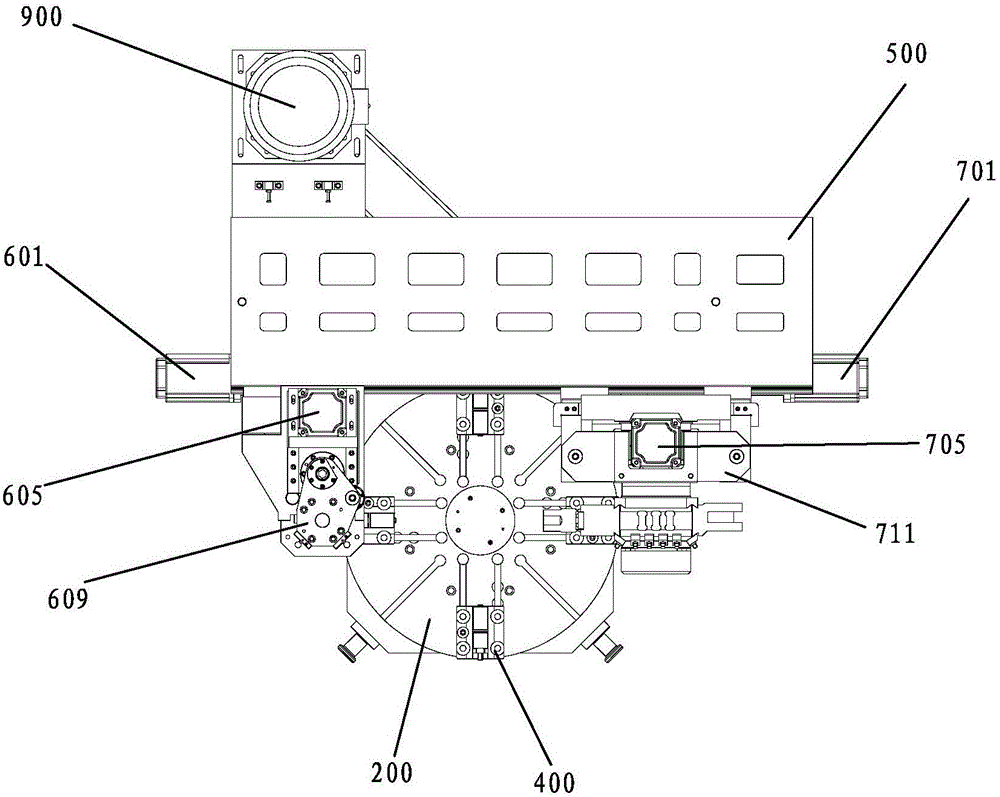

[0089] Such as Figures 1 to 14 As shown, a double-turret double-channel CNC vertical lathe includes a bed 100, a base 300, a workbench 200 arranged on the base 300, a chuck 400 for clamping a workpiece 800, and a bed 100. The fixed beam 500, the tool rest assembly arranged on the fixed beam 500, and the numerical control system (not shown in the figure) used to control the timing of each component of the lathe, the numerical control system is the 840DSL numerical control system produced by SIEMINS.

[0090] The tool rest assembly includes a first slide box 600 and a second slide box 700 that can slide horizontally relative to the fixed beam 500 , and also includes a first feed mechanism for driving the first slide box 600 to move on the fixed beam 500 . A feed mechanism includes a first servo motor 601, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com