A railway-specific multifunctional steel coil transport vehicle

A multi-functional, transport vehicle technology, which is applied in the transportation of passenger cars, railway car body parts, transportation and packaging, etc. The effect of load utilization, improved safety and comfort, and convenient maintenance and repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be specifically described below in conjunction with the accompanying drawings and embodiments.

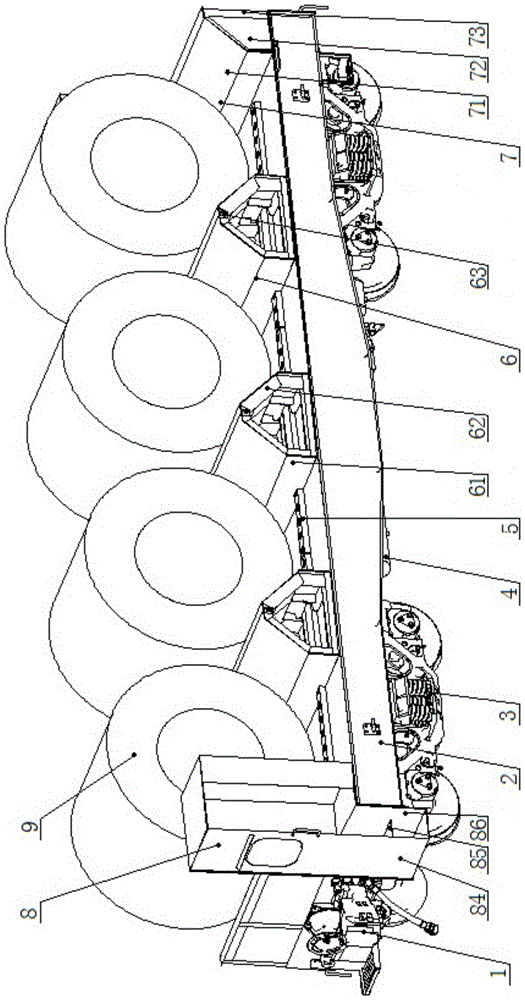

[0017] figure 1 Shown is the structure and loading schematic diagram of the present invention.

[0018] figure 2 Shown is a schematic left view of the structure of the present invention.

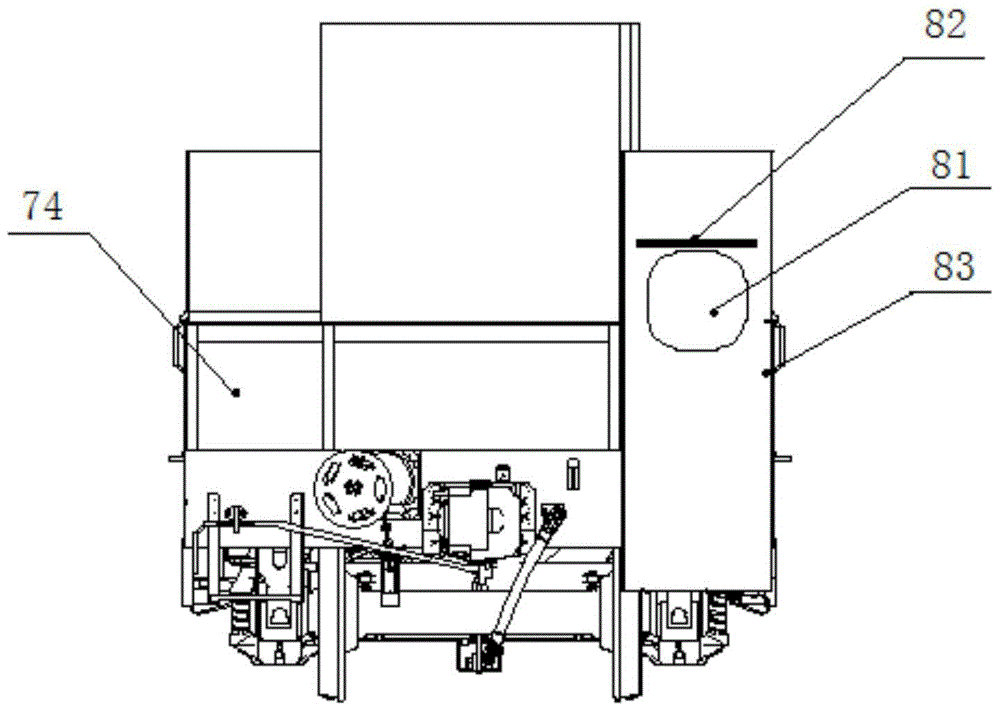

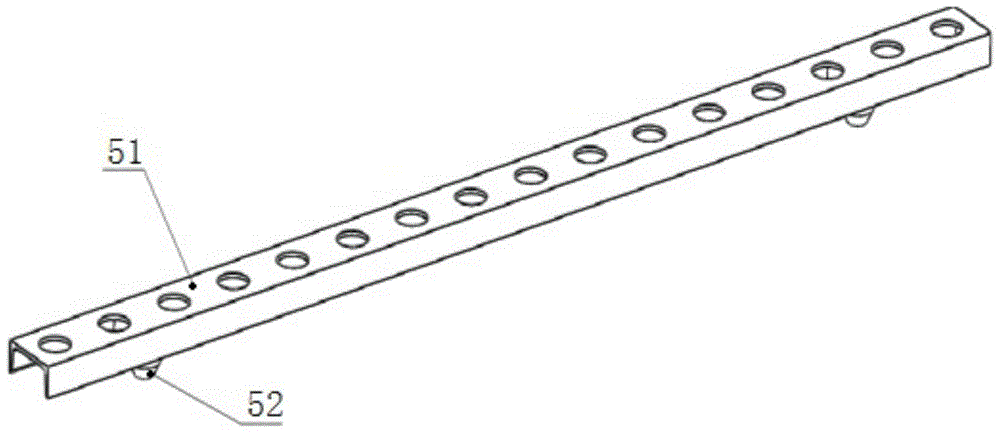

[0019] The present invention includes a rectangular underframe 2, two bogies 3, two coupler buffer devices 1, several brake devices 4, two personnel protection devices 8, two fixed support devices 7, six limit devices 5 and At least 2 adjustable support devices 6.

[0020] The bottom of the rectangular underframe 2 is provided with two upper center plates, the bogie 3 is provided with a lower center plate, and the rectangular underframe 2 is located on the bogie 3 through the upper center plate and the lower center plate for carrying the car body .

[0021] A plurality of braking devices 4 are provided on the bottom of the rectangular underframe 2 and on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com