A kind of oil and gas well solid corrosion inhibitor and preparation method thereof

A corrosion inhibitor and technology for oil and gas wells, applied in chemical instruments and methods, earthwork drilling and production, wellbore/well components, etc., can solve the problems of high cost of dosing, negative impact on the environment, and large consumption of chemicals, and achieve significant Economic effect, increase crude oil gas volume, and reduce production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

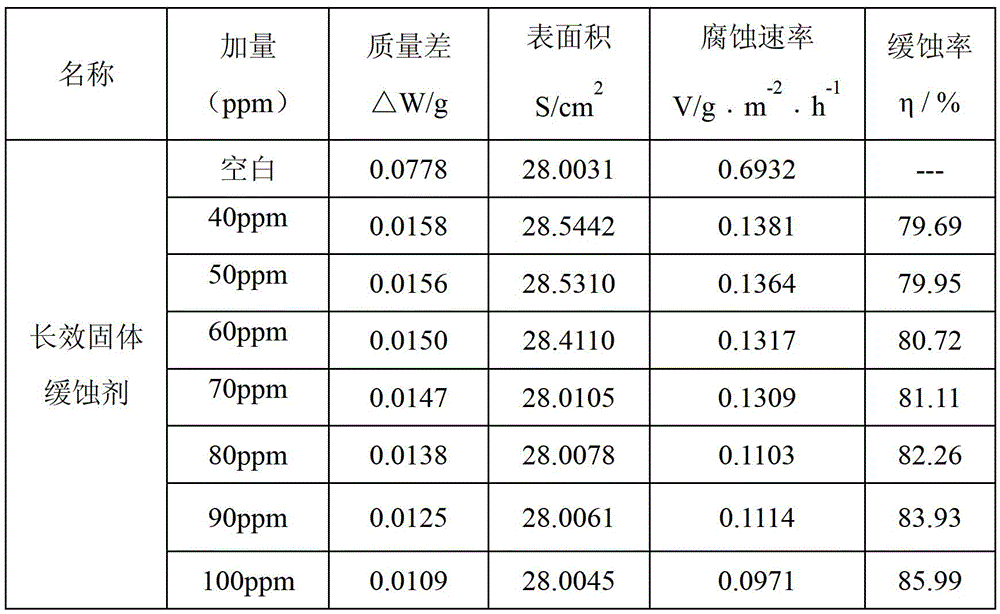

Examples

Embodiment 1

[0017] The long-acting solid corrosion inhibitor of the present invention is synthesized from the following raw materials in mass ratio: 47% of modified rosin, 15% of polyol, 32% of main agent, 3% of toughening agent and 3% of barium sulfate.

[0018] The main agent of the invention is polyoxyethylene naphthenic acid imidazoline, the modifying agent is polyvinyl alcohol, the polyhydric alcohol is glycerol, and the toughening agent is polyvinyl acetate.

[0019] The concrete preparation method of solid corrosion inhibitor of the present invention comprises the steps:

[0020] A. Synthesis of modified rosin: Put rosin in a stirring bottle, turn on the heater, and stir while heating. When the temperature reaches 250°C, add polyvinyl alcohol and keep stirring, keep the temperature for 2 hours, and turn off the heating after the reaction is completed. device, cooled to room temperature, that is, the modified rosin.

[0021] B. Preparation of long-acting solid corrosion inhibitor: ...

Embodiment 2

[0023] The long-acting solid corrosion inhibitor of the present invention is synthesized from the following raw materials in mass ratio: 48% of modified rosin, 16.5% of polyol, 33% of main agent, 1% of toughening agent and 1.5% of barium sulfate.

[0024] The main agent of the invention is polyoxyethylene naphthenic acid imidazoline, the modifying agent is polyvinyl alcohol, the polyhydric alcohol is pentaerythritol, and the toughening agent is polyvinyl acetate.

[0025] The concrete preparation method of long-acting solid corrosion inhibitor of the present invention comprises the following steps:

[0026] A. Synthesis of modified rosin: put rosin in a stirring bottle, turn on the heater, and stir while heating. When the temperature reaches 260°C, add polyvinyl alcohol and keep stirring, keep the temperature for 3 hours, and turn off the heating after the reaction is completed. device, cooled to room temperature, that is, the modified rosin.

[0027] B. Preparation of long-a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com