High temperature and wear resistant double-layer composite hearth roll

A double-layer composite, high-temperature-resistant technology, applied in furnaces, furnace components, furnace types, etc., can solve problems affecting product quality and normal production, roll surface oxidation, furnace roll nodules, etc., to solve the problems of roll surface oxidation, surface Smooth and delicate, not easy to fall off effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

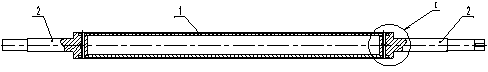

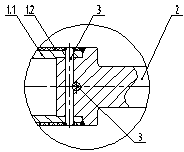

[0016] The high-temperature-resistant and wear-resistant double-layer composite hearth roller shown in the accompanying drawings includes a roller 1 and a roller shaft 2 connected to both ends of the roller 1; the roller shaft 2 is inserted into the end of the roller 1 to form a fit and fixed connection; the roller The cylinder 1 is a double-layer composite cylinder composed of an alloy layer 1.1 on the inner layer and a quartz ceramic layer 1.2 covering the outer layer. In this way, the present invention has the characteristics of high strength, high temperature resistance, small thermal expansion, good chemical stability, stable high temperature performance, no deformation, smooth and fine surface, good wear resistance, etc. Tumor problem, will not produce loose and peeling phenomenon.

[0017] In order to improve the reliability and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com