Logistics delivery route optimizing generation method and system

A route and logistics technology, applied in logistics, instruments, data processing applications, etc., can solve the problems of complex roads, difficult to promote, and high requirements for technical support capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

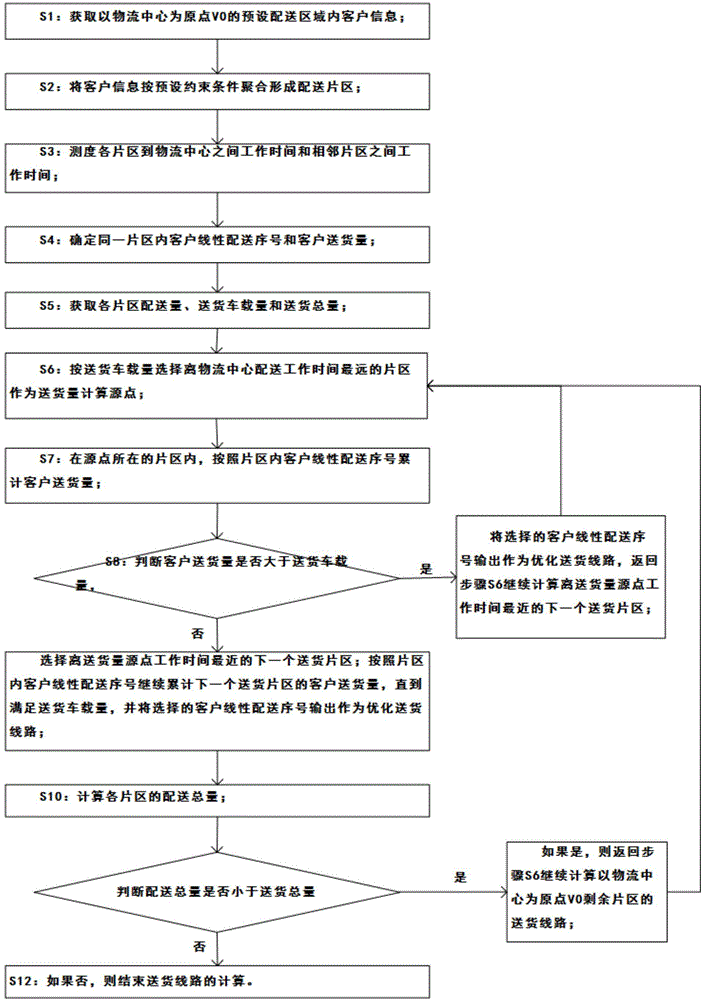

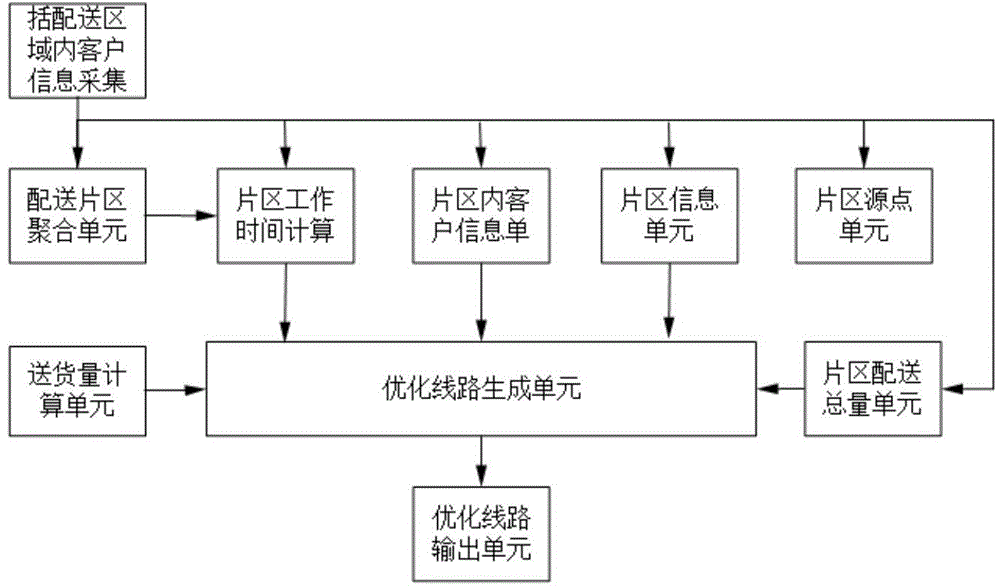

[0082] figure 1 The flow chart of Example 1 of the method for generating an optimized logistics delivery route provided by the embodiment of the present invention is shown in the figure: a method for generating an optimized logistics delivery route provided by the present invention includes the following steps:

[0083] S1: Obtain customer information in the preset delivery area with the logistics center as the origin V0;

[0084] S2: Aggregate customer information according to preset constraints to form a distribution area;

[0085] S3: Measure the working time between each area and the logistics center and the working time between adjacent areas;

[0086] S4: Determine the customer's linear delivery sequence number and the customer's delivery volume in the same area;

[0087] S5: Obtain the distribution volume, delivery vehicle volume and total delivery volume of each area;

[0088] S6: Select the area farthest away from the distribution working hours of the logistics cen...

Embodiment 2

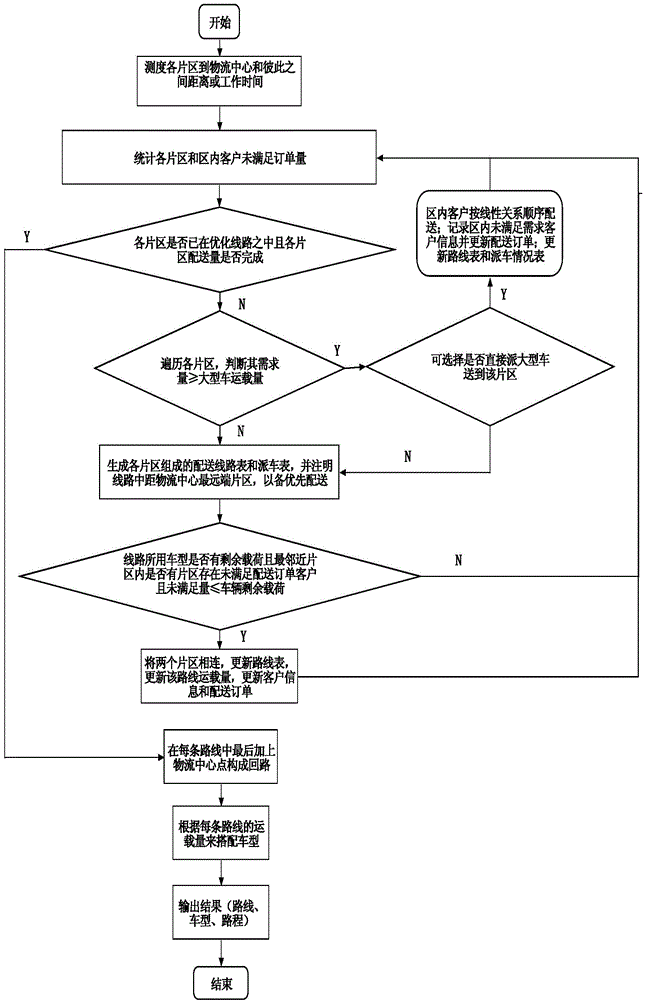

[0147] image 3 The flow chart of Embodiment 2 of the logistics delivery route optimization generation method provided by the embodiment of the present invention, as shown in the figure, the only difference between this embodiment and Embodiment 1 is:

[0148] S21: Acquiring customer delivery point information in the delivery area;

[0149] S22: Aggregate customer distribution point information according to preset constraints to form a distribution area;

[0150] S23: Measure the distance from each area to the logistics center and the area;

[0151] S24: Obtain the unsatisfied orders of customers in each area and in the area;

[0152] S25: Judging whether each area is in the optimized route list and whether the delivery volume of each area is completed;

[0153] S26: If yes, proceed to step S; if no, traverse each area to determine whether the required delivery volume is less than the carrying capacity of large vehicles;

[0154] S27: If not, judge whether to choose to sen...

Embodiment 3

[0163] Figure 4 The working process diagram of Embodiment 3 of the logistics delivery route optimization generation method provided by the embodiment of the present invention, as shown in the figure, the difference between this embodiment and Embodiment 1 is only:

[0164] In the figure, A is the distribution center, that is, the calculation source point; each point in the figure constitutes the area that needs to be reached during the distribution process; the value between points is determined by time, and can also be understood as between points On the basis of the length of the path, add the time constraints of each point (such as: parking time, unloading time, etc.), and then convert it into a working time condition.

[0165]The following example specifically illustrates the working process of the logistics delivery route optimization generation method provided in this embodiment:

[0166] a) Let the logistics center be the origin V0, W is the set of customer areas Vm (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com