XLPE insulated non-extrusion shielded medium voltage power cable production process

A cross-linked polyethylene, power cable technology, applied in cable/conductor manufacturing, circuits, electrical components, etc., can solve the problem of time-consuming and laborious, and achieve the effect of reducing cost, reducing outer diameter, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In the following, the present invention will be further illustrated through examples in conjunction with the drawings.

[0024] The production process of XLPE insulated non-extrusion shielded medium voltage power cable includes the following process steps:

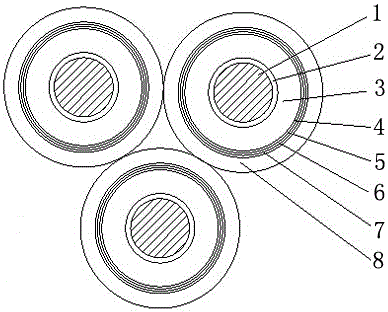

[0025] ① XLPE insulated non-extrusion shielded medium voltage power cable, including conductor core 1, inner shielding layer 2, insulating layer 3, silicone oil layer 4, wrapped semi-conductive tape shield 5, wrapped copper tape shield 6 , Wrap non-woven fabric 7 and environmental protection PVC sheath 8;

[0026] ②The conductor core adopts a compacted conductor. During the conductor production, an antioxidant is added to prevent the copper wire from oxidizing during the production process. The conductor core 1 is sequentially covered with an inner shielding layer 2, an insulating layer 3, a silicone oil layer 4, and a half-wrapped layer. Conductive tape shield 5, wrapped copper tape shield 6, wrapped non-woven fabric 7 a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap