Carbon nanofiber heating cloth

A nano carbon fiber, carbon fiber technology, applied in ohmic resistance heating, electric heating devices, electrical components, etc., can solve the problems of uneven heating and short service life of carbon fiber heating cloth, and achieve good heating effect, high specific modulus and high strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

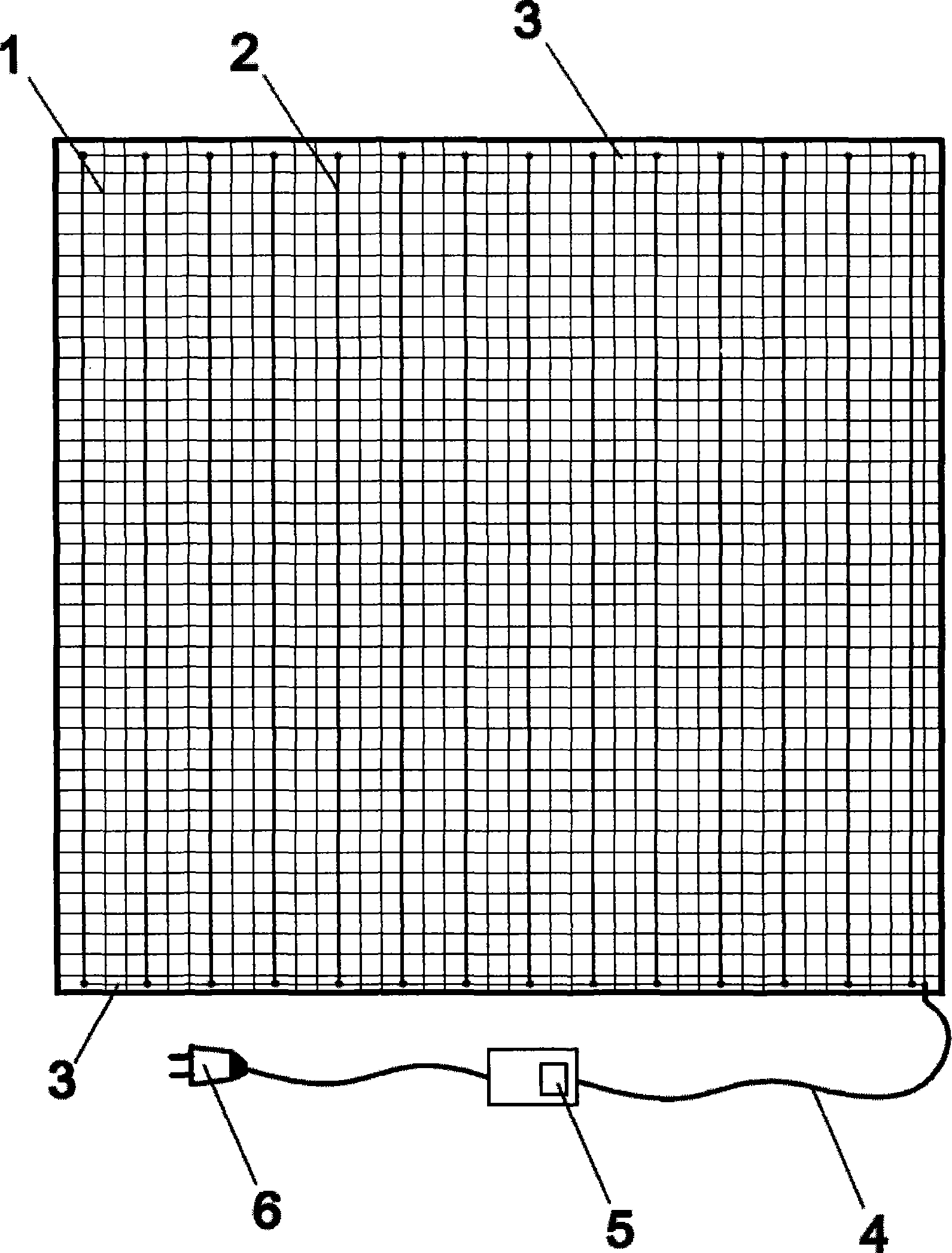

[0028] The structural diagram of nano carbon fiber heating cloth of the present invention is as follows figure 1 As shown, it includes an insulating fiber braid woven by insulating fiber 1 warp and weft, and several carbon nanofibers 2 are interspersed in parallel in the radial direction of the insulating fiber braid. The two ends of the electrode 3 and the controller 5 are connected between the power plug 6 and the power line 4 .

[0029] When the carbon nanofiber 2 is energized, it is converted into heat energy by the carbon nanofiber 2 and radiated outward in the form of far-infrared radiation. Since the heating component uses carbon nanofibers, the carbon nanofibers have low density, high specific modulus, high Strength, high conductivity, good thermal stability and large specific surface area, so the nano-carbon fiber heating cloth made of nano-ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com