Method for producing pleurotus cornucopiae through bagasse, mulberry stems and corn residues

A technology of corn bagasse and sugarcane bagasse, which is applied in the direction of botany equipment and methods, applications, fertilizer mixtures, etc., can solve the problems of not being able to accelerate the decomposition of raw materials, not adding fermentation bacteria, and low biological efficiency, so as to improve the biological efficiency of raw materials , Increase the yield of Jiji mushroom and enrich the effect of nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

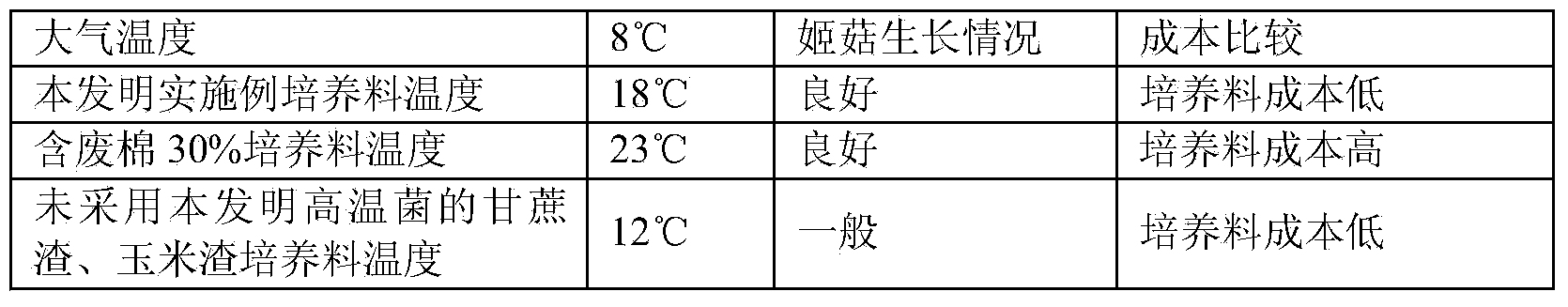

Examples

Embodiment 1

[0040] Composting of mushroom compost:

[0041] A: First crush 50 kg of bagasse, 5 kg of mulberry stalks and 10 kg of corn dregs, add 2 kg of high-temperature bacteria and mix thoroughly, dissolve 2 kg of lime in water, take the supernatant and pour it on the mixed raw materials to control the water content of 65-70 %, the pH value is 8-9, covered with a film, composted and fermented for 2-5 days;

[0042] B: Turn over the fermented cultivation material, then sprinkle 5 kg of peanut bran and 3 kg of fish meal into the culture material, mix well, start the pile again, and cover it with a film to ferment for 2 days. After turning the pile 2-3 times in this way, mix Evenly, heat up to 70-80°C, keep for 15 hours for sterilization, then cool down to 20-28°C.

[0043] The above-mentioned high-temperature bacteria are composite bacteria of lactic acid bacteria, Bacillus subtilis and cellulolytic bacteria, and the parts by weight are 1:1:1. The cultivation process requires high-tempe...

Embodiment 2

[0050] Composting of mushroom compost:

[0051] A: First crush 70 kg of bagasse, 15 kg of mulberry stalks and 30 kg of corn dregs, add 3 kg of high-temperature bacteria and mix thoroughly, dissolve 4 kg of lime in water, take the supernatant and pour it on the mixed raw materials to control the water content of 65-70 %, the pH value is 8-9, covered with a film, composted and fermented for 2-5 days;

[0052] B: Turn over the fermented cultivation material, then sprinkle 15 kg of peanut bran and 7 kg of fish meal into the culture material, mix well, start the pile again, and cover with film to ferment for 2 days. After turning the pile 2-3 times in this way, mix Evenly, heat up to 70-80°C, keep for 15 hours for sterilization, then cool down to 20-28°C.

[0053] The above-mentioned high-temperature bacteria are composite bacteria of lactic acid bacteria, Bacillus subtilis and cellulolytic bacteria, and the parts by weight are 1:1:1. The cultivation process requires high-temperat...

Embodiment 3

[0060] Composting of mushroom compost:

[0061] A: First crush 60 kg of bagasse, 10 kg of mulberry stalks and 20 kg of corn dregs, add 4 kg of high-temperature bacteria and mix thoroughly, dissolve 3 kg of lime in water, take the supernatant and pour it on the mixed raw materials to control the water content of 65-70 %, the pH value is 8-9, covered with a film, composted and fermented for 2-5 days;

[0062] B: Turn over the fermented cultivation material, then sprinkle 10 kg of peanut bran and 5 kg of fish meal into the culture material, mix well, start the pile again, and cover with film to ferment for 2 days. After turning the pile 2-3 times in this way, mix Evenly, heat up to 70-80°C, keep for 15 hours for sterilization, then cool down to 20-28°C.

[0063] The above-mentioned high-temperature bacteria are composite bacteria of lactic acid bacteria, Bacillus subtilis and cellulolytic bacteria, and the parts by weight are 1:1:1. The cultivation process requires high-temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com