AAO-MBR process and apparatus for synchronously removing nitrogen and phosphorus

A simultaneous denitrification and dephosphorization technology, applied in water/sewage multi-stage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problem of increasing the operating cost of the membrane separation process and limiting engineering applications, etc. problems, to achieve the effect of alleviating membrane fouling and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

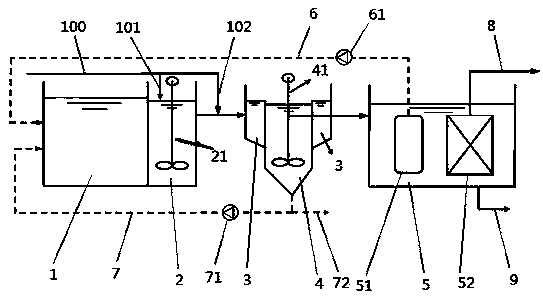

[0028] figure 1 The reference numerals in the figure are: sewage inlet pipe 100; first sewage inlet pipe 101; second sewage inlet pipe 102; anoxic pool 1; anaerobic pool 2; first agitator 21; aerobic pool 3; sedimentation tank 4 ; second agitator 41; MBR reaction tank 5; non-woven fabric filter 51; MBR membrane assembly 52; Sludge discharge pipe 72 ; drain pipe 8 ; second excess sludge discharge pipe 9 .

[0029] The present invention needs to solve the problems of difficulty in further improving the phosphorus and nitrogen removal capacity of the traditional A2 / O process, insufficient utilization of carbon sources, long process, large floor area and high energy consumption caused by membrane fouling in the MBR process. The present invention proposes a simultaneous denitrification and dephosphorization MBR process that can make full use of ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com