Potassium-toning manganese-containing colored glass and sintering method thereof

A technology of colored glass and content, applied in the field of inorganic non-metallic materials, can solve the problems of large color difference of glass and difficult control of the color of manganese-containing glass, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

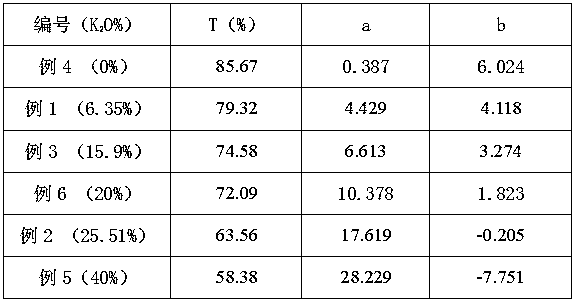

Embodiment 1

[0017] A potassium-toned manganese-containing colored glass, which is fired from silicon oxide, calcium oxide, manganese oxide, sodium nitrate and toner potassium oxide. The contents of each component of the colored glass are 88% silicon oxide, 0% calcium oxide, 0.15% manganese oxide, 5.5% sodium nitrate and 6.35% potassium oxide.

[0018] The firing method of the manganese-containing colored glass of above-mentioned potassium tinting, comprises the following steps:

[0019] 1) Select suitable raw materials for batching, and ensure that the content of each component in the selected raw materials meets the ratio of the above requirements;

[0020] 2) The prepared mixture is fully melted at 1468°C, and then annealed at 600°C and drawn into shape to obtain the product.

[0021] Step 2) When the mixture is melting, first raise the temperature uniformly to 200°C within 60-70 minutes, then raise the temperature from 200°C to 1468°C within 170-180 minutes, and keep the temperature a...

Embodiment 2

[0023] A manganese-containing colored glass toned by potassium, which is fired from silicon oxide, calcium oxide, manganese oxide, sodium nitrate and toner potassium oxide. The contents of each component of the colored glass are 50% silicon oxide, 24% calcium oxide, 0.15% manganese oxide, 0.34% sodium nitrate and 25.51% potassium oxide.

[0024] The firing method of the manganese-containing colored glass of above-mentioned potassium tinting, comprises the following steps:

[0025] 1) Select suitable raw materials for batching, and ensure that the content of each component in the selected raw materials meets the ratio of the above requirements;

[0026] 2) Fully melt the prepared mixture at 1468°C, and anneal at 600°C after molding to obtain the product.

[0027] Step 2) When the mixture is melting, first raise the temperature uniformly to 200°C within 60-70 minutes, then raise the temperature from 200°C to 1468°C within 170-180 minutes, and keep the temperature at 1468°C unti...

Embodiment 3

[0029] A manganese-containing colored glass toned by potassium, which is fired from silicon oxide, calcium oxide, manganese oxide, sodium nitrate and potassium oxide as a toner. The contents of each component of the colored glass are 69% silicon oxide, 12% calcium oxide, 0.15% manganese oxide, 2.95% sodium nitrate and 15.9% potassium oxide.

[0030] The firing method of the manganese-containing colored glass of above-mentioned potassium tinting, comprises the following steps:

[0031] 1) Select suitable raw materials for batching, and ensure that the content of each component in the selected raw materials meets the ratio of the above requirements;

[0032] 2) Fully melt the prepared mixture at 1468°C, and anneal at 600°C after molding to obtain the product.

[0033] Step 2) When the mixture is melting, first raise the temperature uniformly to 200°C within 60-70 minutes, then raise the temperature from 200°C to 1468°C within 170-180 minutes, and keep the temperature at 1468°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com