Preparation method of edible essence 8-mercaptomenthone

A kind of sulfhydryl horse, synthesis method technology, applied in the field of edible flavor preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

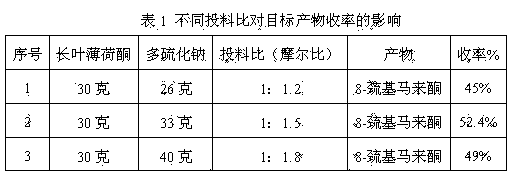

[0021] Add 300 grams of menthol, 250 grams of sodium polysulfide and 1000 grams of water into the reactor, stir and mix evenly, heat to 80°C to 90°C, and react for 12 hours under constant stirring. Then the above reaction mixture was diluted with water, acidified to neutral with hydrochloric acid, cooled to room temperature, filtered, and the filter cake was washed with warm water at a temperature of 35° C. to 40° C. to obtain 310 g of crude 8-mercaptomaleone.

[0022] Add 310 grams of crude 8-mercaptomaleone into the reaction vessel, then add 400 grams of ethanol to reflux for 4 hours, then cool the solution to room temperature, precipitate a solid, then filter, and vacuum-dry the filtered solid to constant weight to obtain the final product 195 grams of 8-mercaptomaleone, the yield is 52.4%, which is better than the bibliographical reports of the existing normal pressure reaction.

[0023] The NMR parameters of the prepared 8-mercaptomaleone are:

[0024] 1 H-NMR(300MHz,DM...

Embodiment 2

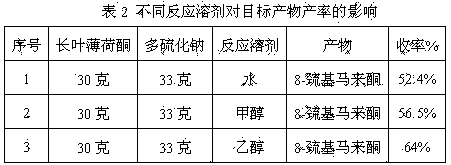

[0027] Add 300 grams of menthol, 330 grams of sodium polysulfide and 1000 grams of methanol into the reactor, stir and mix evenly, heat to 80°C to 90°C, and react for 12 hours under constant stirring. Then the above reaction mixture was diluted with water, acidified to neutral with hydrochloric acid, cooled to room temperature, filtered, and the filter cake was washed with warm water at a temperature of 35° C. to 40° C. to obtain 305 g of crude 8-mercaptomaleone.

[0028] Add 305 grams of crude 8-mercaptomaleone into the reaction vessel, then add 400 grams of ethanol to reflux for 4 hours, then cool the solution to room temperature, precipitate a solid, then filter, and vacuum-dry the filtered solid to constant weight to obtain the final product 210 grams of 8-mercaptomaleone, the yield is 56.5%.

Embodiment 3

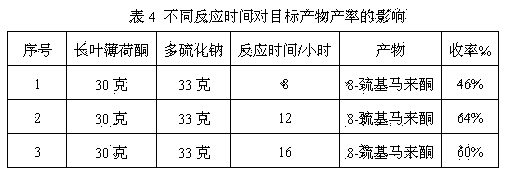

[0030] Add 300 grams of menthone, 400 grams of sodium polysulfide and 1200 grams of ethanol to the reactor, stir and mix evenly, heat to 80 ° C ~ 90 ° C, add 5 g of zinc chloride (Friedel-Crafts catalyst), under constant stirring React for 12 hours. Then the above reaction mixture was diluted with water, acidified to neutral with hydrochloric acid, cooled to room temperature, filtered, and the filter cake was washed with warm water at a temperature of 35° C. to 40° C. to obtain 320 g of crude 8-mercaptomaleone.

[0031] Add 320 grams of crude 8-mercaptomaleone into the reaction vessel, then add 400 grams of ethanol to reflux for 4 hours, then cool the solution to room temperature, precipitate a solid, then filter, and vacuum-dry the filtered solid to constant weight to obtain the final product 220 grams of 8-mercaptomaleone, the yield is 59%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com