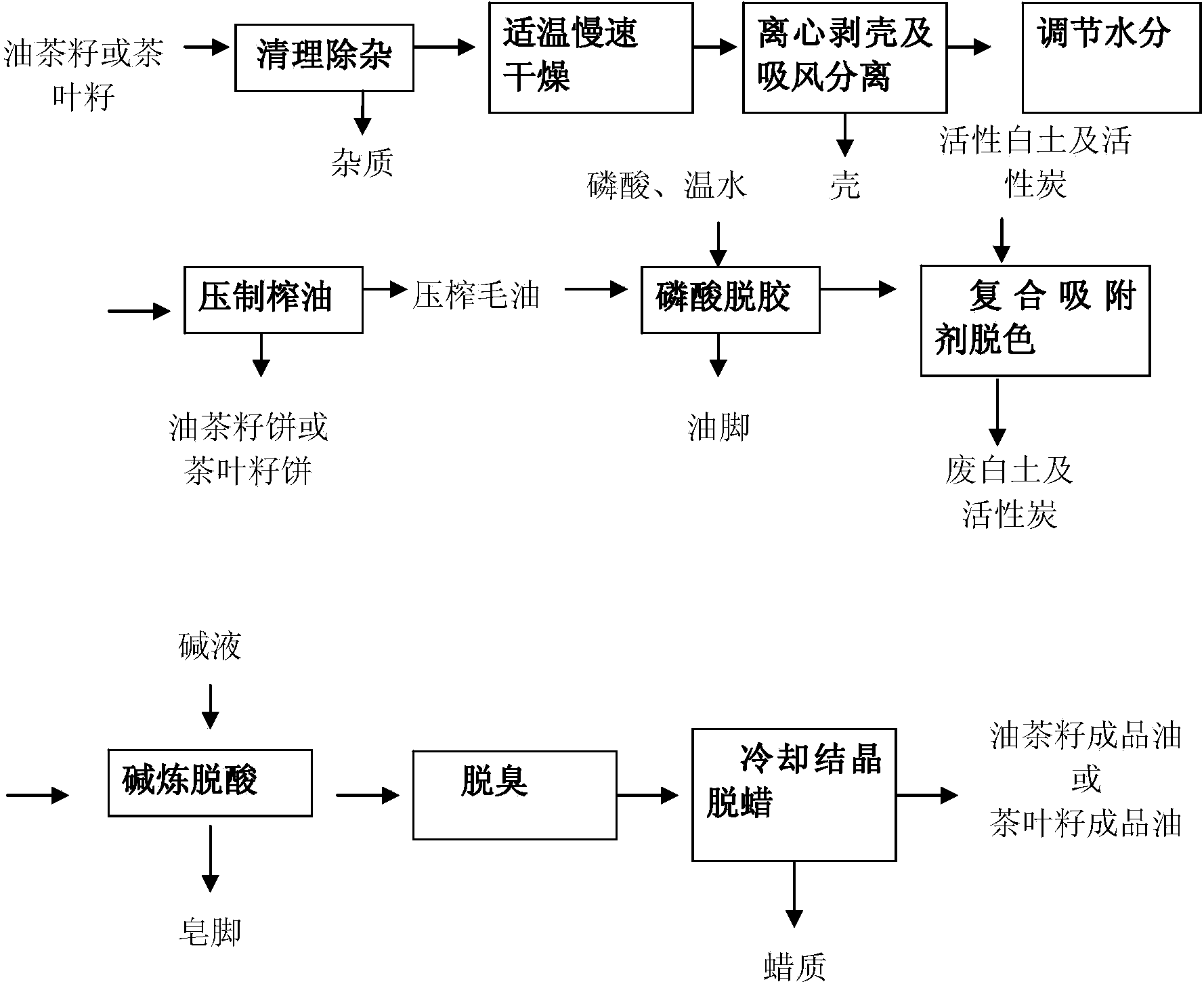

Production method for preparing and refining oil from tea seeds or camellia seeds

A production method and technology for camellia seeds, which are applied in the directions of oil/fat production, oil/fat refining, and fat production, can solve the problem that the edible safety of camellia seeds and tea seed oil products cannot be guaranteed, and the natural ingredients cannot be well preserved. Eliminate astringent bitterness and peculiar smell, achieve good taste and nutrition, improve oil flavor and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. Raw materials of camellia oleifera or tea seeds are cleaned and removed by screening equipment;

[0035] 2. Send the oil-tea camellia seeds or tea seeds after cleaning and removing impurities to a dryer (such as the PHGJ dryer produced by Anlu Tianxing Grain and Oil Machinery Equipment Co., Ltd.), and dry the oil-tea camellia seeds after cleaning and removing impurities at 70°C. Seeds or tea seeds are circulated and dried, and the dried camellia seeds or tea seeds are allowed to cool down and then returned to the dryer for drying at a suitable temperature. This cycle is repeated several times to reduce the moisture content of the material to the moisture contained in the grains. Gradually spread to the surface to reduce the moisture content of the material to less than 13%, so as to facilitate shelling and separation of kernels and shells.

[0036] 3. After drying, the camellia seed or tea seed adopts an impact shelling machine (such as the CLBK model tea seed centri...

Embodiment 2

[0046] 1. Raw materials of camellia oleifera or tea seeds are cleaned and removed by screening equipment

[0047] 2. Send the cleaned and removed camellia seeds or tea seeds to the dryer, and cycle dry the cleaned and removed camellia seeds or tea seeds at 80°C, and let the once-dried camellia seeds or tea seeds stand After cooling, return to the dryer to dry at a suitable temperature. This cycle is repeated several times to reduce the moisture content of the material to the point where the moisture contained in the grain gradually diffuses to the surface, so that the moisture content of the material is reduced to less than 10%, so as to facilitate shelling and drying. Kernel shells are separated.

[0048] 3. After drying, the camellia seed or tea seed is peeled by impact peeling machine, and the peeling rate reaches 85%. Then the kernel and the shell are separated through the vertical air suction channel according to the difference in the suspension speed of the kernel and t...

Embodiment 3

[0058] 1. Raw materials of camellia oleifera or tea seeds are cleaned and removed by screening equipment;

[0059] 2. Send the cleaned and removed camellia seeds or tea seeds to the dryer, and cycle dry the cleaned and removed camellia seeds or tea seeds at 75°C, and let the once-dried camellia seeds or tea seeds stand After cooling, return to the dryer for drying at a suitable temperature. This cycle is repeated several times to reduce the moisture content of the material to the point where the moisture contained in the grain gradually diffuses to the surface, so that the moisture content of the material is reduced to less than 12%, which is beneficial to shelling and drying. Kernel shells are separated.

[0060] 3. After drying, the camellia seed or tea seed adopts an impact shelling machine (such as the CLBK model tea seed centrifugal shelling and shell kernel separation unit produced by Anlu Tianxing Grain and Oil Machinery Equipment Co., Ltd., which has both centrifugal s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com