Flexible corrosion-resisting drag chain cable

A drag chain cable and corrosion-resistant technology, applied in the direction of insulated cables, bendable cables, cables, etc., can solve the problems of manufacturers' losses, production stoppages, etc., and achieve high bending resistance, good wear resistance, and high conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

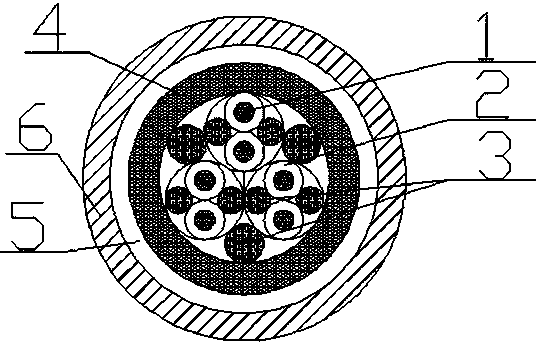

[0008] Such as figure 1 As shown, the flexible corrosion-resistant towline cable of the present invention adopts 6 types of soft copper conductors 1 to extrude the elastomer insulating layer 2; the cable has good flexibility and elasticity, so that the cable has a longer service life; The cores are twisted and the side gaps of the cables are filled with filling strips 3, and the twisted joint diameter ratio is 6 to 8 times during the twisting and cable formation, so as to meet the requirements for the bending radius during the cable laying and installation process. It is filled with a filler strip 3 made of elastic fiber insulating material extruded outside the tensile fiber rope to ensure the roundness of the cable; the cable core is covered with a thin polyester tape 4; a layer of braided shielding layer 5 is braided outside the tape; The shielding layer 5 is extruded with a polyurethane outer sheath 6. The two materials have excellent properties such as ultra-high flexibili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com