Method for preparing instant buckwheat tea

A kind of buckwheat tea, instant technology, applied in the field of food processing, can solve the problems of shortage, etc., achieve the effect of reducing the loss of flavonoids, strong free radical scavenging ability, and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

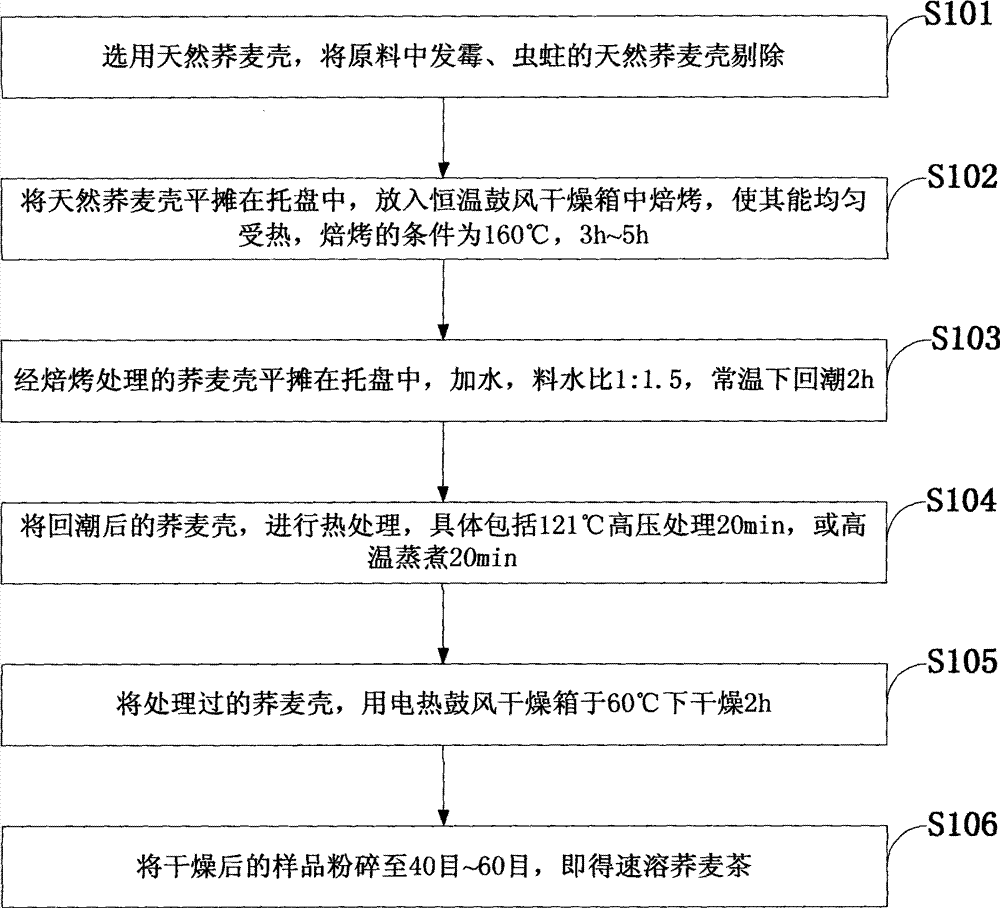

[0034] like figure 1 Shown, the preparation method of the instant buckwheat tea of the embodiment of the present invention comprises the following steps:

[0035] S101: Select natural buckwheat husks, and remove moldy and moth-eaten natural buckwheat husks from the raw materials;

[0036] S102: Spread the natural buckwheat husks on a tray, put them into a constant temperature blast drying oven and bake them so that they can be heated evenly. The baking conditions are 140-160°C for 3h-5h;

[0037] S103: Spread the roasted buckwheat husks on a tray, add water, the ratio of material to water is 1:1-2, and rehydrate at room temperature for 1-2 hours;

[0038] S104: heat-treat the rehydrated buckwheat hulls, specifically including high-pressure treatment at 100-120°C for 20-30 minutes, or high-temperature cooking for 20-30 minutes;

[0039] S105: drying the treated buckwheat husks in an electric blast drying oven at 60-80°C for 2-3 hours;

[0040] S106: crush the dried sample ...

Embodiment 1

[0046] Choose natural buckwheat husks, screen them, remove stones and impurities, and the grain shape is uniform. Weigh 100g of raw material, lay it flat on a tray after cleaning, dry it in a thermoelectric blast dryer at 60-80°C for 2h-3h, crush it to 40-60 mesh, seal it in a paper bag, and obtain buckwheat tea.

Embodiment 2

[0048] Choose natural buckwheat husks, screen them, remove stones and impurities, and the grain shape is uniform. Weigh 100g of raw material, clean it and spread it on a tray, bake it in a thermoelectric blower dryer at 140-160°C for 3h-5h, take it out, add 150-200mL of water to rehydrate it for 1-2h, and then put it in the electric blast dryer Dry it in a box at 60-80°C for 2h-3h, crush it to 40-60 mesh, pack it in a sealed paper bag, and obtain buckwheat tea.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com