Preparation method of PPS superfine fiber compound filter material

A technology of ultra-fine fiber and composite filter material, which is applied in separation methods, chemical instruments and methods, filtration separation, etc., and can solve the problems of low PM2.5 filtration efficiency, poor oxidation resistance, poor tolerance, and low dust emission concentration , to achieve the effect of improving anti-oxidation performance, reducing filtration resistance and reducing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

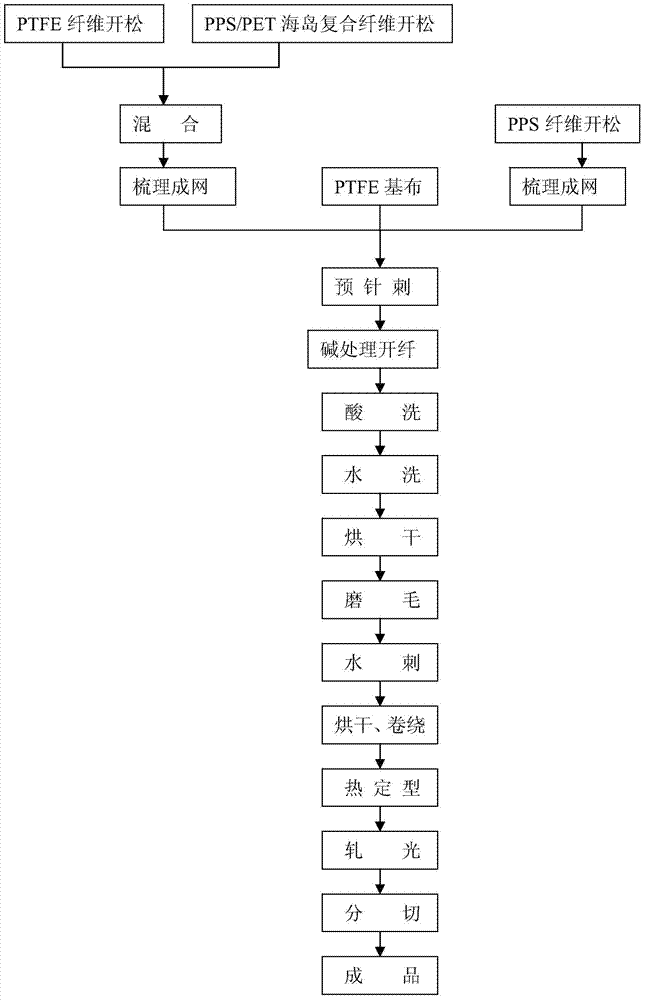

[0020] A preparation method of the PPS superfine fiber composite filter material according to the present invention, in which the dust facing surface adopts PPS / PET sea-island composite fiber and PTFE fiber blending, wherein the weight ratio of PPS / PET sea-island composite fiber is 40 -60%; the base fabric is made of 100% PTFE filament interwoven in warp and weft; the net air surface is made of 100% PPS fiber; the dust surface is made of PPS ultra- Composite needle-punched felt with fine fibers, and then through spunlace reinforcement and post-finishing treatment, is prepared into PPS ultra-fine fiber composite filter material; the specific steps are as follows:

[0021] (1) Open PPS / PET sea-island composite fibers and PTFE fibers respectively, and then mix the two fibers evenly;

[0022] (2) Combing and cross-lapping the uniformly mixed composite fiber web to form a dust-facing surface; the weight ratio of PPS / PET sea-island composite fibers in the dust-facing surface is 40-6...

Embodiment 1

[0031] The dust-facing surface is mixed with 2.2dtex PPS / PET sea-island composite fibers and 2.2dtex PTFE fibers to obtain a mixed fiber web, in which the proportion of PPS / PET sea-island composite fibers is 40%; the base fabric is made of 2.2dtex PTFE filaments interwoven in warp and weft; 2.2dtex PPS fiber mesh with 100% net air side; as above figure 1 Processing technology, made of PPS superfine fiber composite filter material. Among them, the mass concentration of NaOH in alkali treatment is 25g / L, the temperature of alkali solution is 100°C, and the heating time is 70min. It is washed 3 times with 5g / L HAc solution, rinsed with water for 5 times and baked at 105°C for 0.5h; spunlace reinforcement process The pressure of the water needle is: Spunlace head 1: Double-row needle board 50MPa, Spunlace head 2: Single-row needle board 80MPa, Spunlace head 3: Double-row needle board 150MPa, Spunlace head 4: Single-row needle board 160MPa, water Piercing head 5: single-row needle...

Embodiment 2

[0034]2.2dtex PPS / PET sea-island composite fiber and 2.2dtex PTFE fiber are mixed on the dust-facing surface to obtain composite fiber, in which the proportion of PPS / PET sea-island composite fiber is 50%; the base fabric is made of 2.2dtex PTFE filament warp and weft; The air surface is 100% 2.2dtex PPS fiber net; it is processed according to the above-mentioned figure to make PPS superfine fiber composite filter material. Among them, the mass concentration of NaOH in alkali treatment is 30g / L, the temperature of alkali solution is 110°C, and the heating time is 60min. It is washed 3 times with 5g / L HAc solution, rinsed with water for 5 times and baked at 105°C for 0.5h; spunlace reinforcement process The pressure of the water needle is: Spunlace head 1: Double-row needle board 55MPa, Spunlace head 2: Single-row needle board 85MPa, Spunlace head 3: Double-row needle board 155MPa, Spunlace head 4: Single-row needle board 165MPa, water Piercing head 5: single-row needle plate 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Filter resistance | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com