Rubber composition for tread of truck radial tire with low hysteresis loss

A technology of rubber composition and radial tire, which is applied in special tires, tire parts, rolling resistance optimization, etc. It can solve the problems of difficult processing and unsatisfactory mechanical properties of wear resistance, etc., and achieve low hysteresis loss and excellent fuel economy. Sexuality and the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] In this embodiment, the base rubber is natural rubber. Each component of the composition of the embodiment is in parts by mass, and the specific components are shown in Table 1. The mixing of the rubber composition is carried out according to the above-mentioned preparation method of the rubber composition, and the difference from the above-mentioned preparation method is: vulcanization The rubber is then pressed into a 2.0mm thick film with a small open mill. After parking for 6 hours, use a steam plate vulcanizer to vulcanize the samples for 20min, 30min, and 40min at a temperature of 151°C. The samples are in accordance with relevant national standards. Test performance, in addition, use DMA / SDTA861e dynamic thermodynamic analyzer to test the dynamic performance of the rubber composition, using shear mode, the measurement frequency is 5Hz, the heating rate is 3°C / min, and the temperature range is -20°C to 80°C , the maximum amplitude of the force is 6N, the maximum a...

Embodiment 2

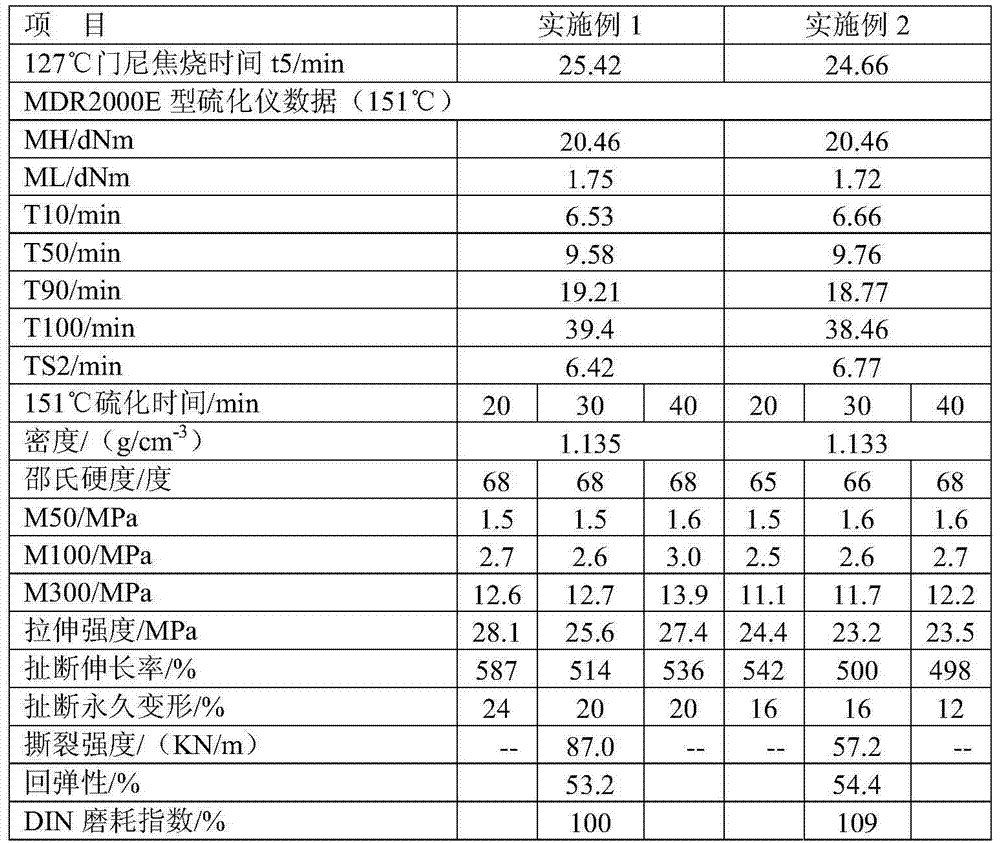

[0048] In this example, the only difference from Example 1 is that the base rubber is used in combination with natural rubber and rare earth butadiene rubber, and the performance test results of the prepared rubber composition are shown in Table 2.

[0049] Table 2 Typical performance

[0050]

[0051] .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com